Reaction tank for bluing process of chain

A reaction pool and process technology, applied in the field of reaction pools in the chain bluing process, can solve the problems of operator damage, inconvenience in operation, and easy sputtering of the bluing liquid on the operator, so as to avoid injury and facilitate delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

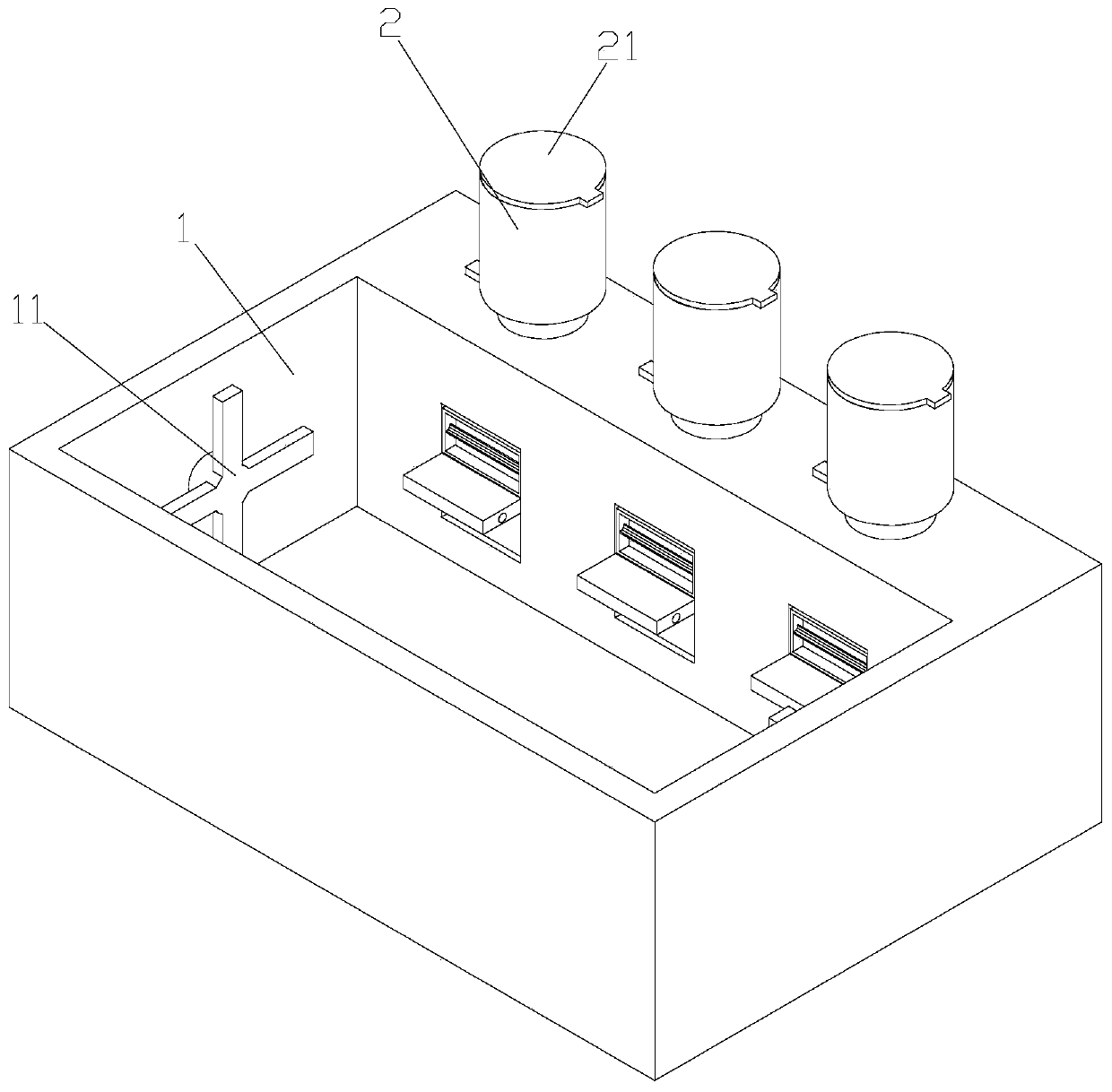

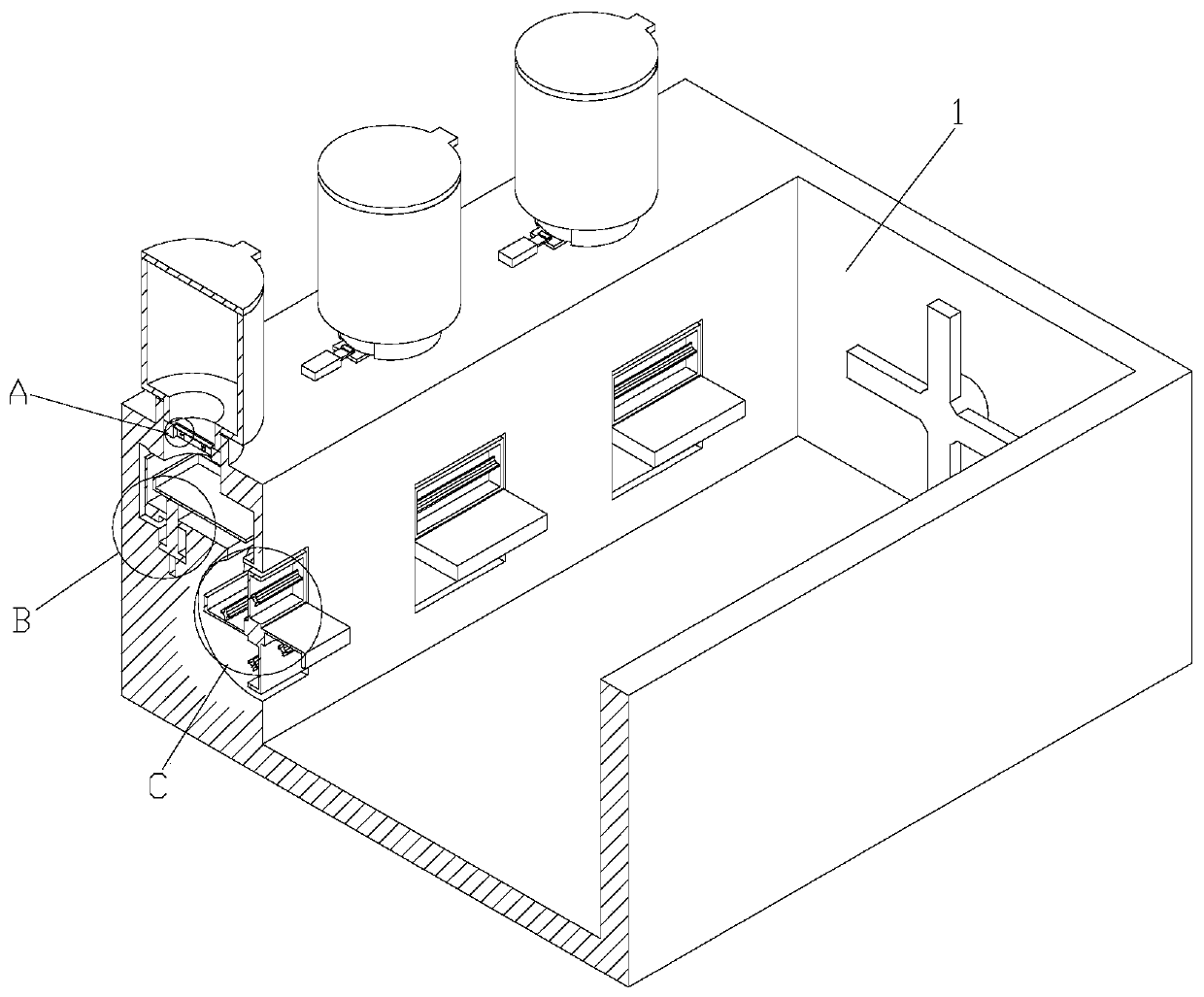

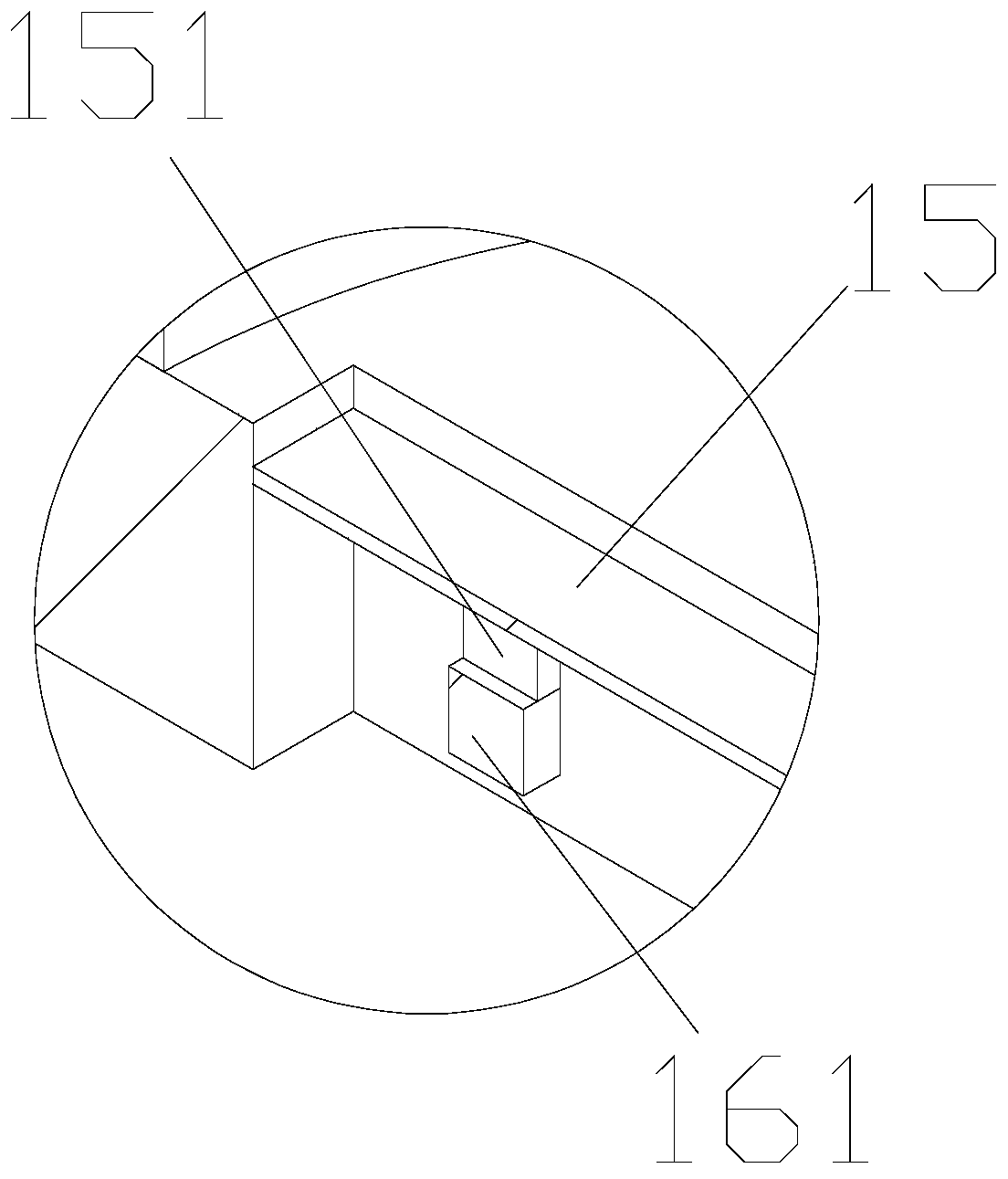

[0027] Such as Figure 1-11 As shown, a reaction pool used for the chain bluing process includes a pool body 1 and a medicine box 2 arranged on the pool body 1, and there are multiple medicine boxes 2 for storing various medicines. The side wall of the pool body 1 is provided with a control panel matched with the medicine box 2, and the top of the medicine box 2 is provided with a first cover plate 21, and one end of the first cover plate 21 is hinged to the medicine box 2. At the top, a push plate is provided on the side wall of the first cover plate 21, under the setting of the first cover plate, so as to directly add the medicine into the medicine box and reduce the difficulty of adding medicine; the side wall of the pool body 1 is provided with The first through cavity communicated with the medicine box 2, the bottom of the first through cavity is provided with a cavity, the cavity is provided with a loading box 18, and the bottom of the cavity is provided with a second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com