Production method of bluing tape for round steel packaging

A production method and blue-ribbon technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of easy fatigue of operators, packaging efficiency, strength of bundled round steel, blue-ribbon breakage, etc., so as to avoid blue-ribbon breakage. hidden dangers, increase product revenue, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

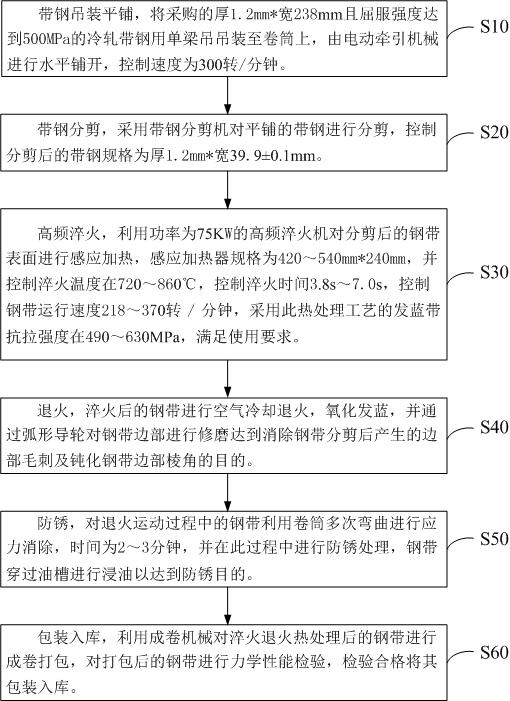

[0037] The steps of the production method of the blue ribbon include: hoisting and flat laying of the strip steel → cutting the strip steel → high-frequency quenching → annealing → rust prevention → packaging and storage.

[0038] The step of hoisting and laying the steel strip: hoist the purchased cold-rolled steel strip with a thickness of 1.2mm*width of 238mm, a tensile strength of 620-680MPa, and a yield strength of 235MPa to the drum with a single beam hoist, and the electric traction machine Spread horizontally, and control the speed at 250-300 rpm.

[0039] The step of dividing and shearing the strip: the step of dividing and shearing the strip specifically includes: adopting a strip dividing and shearing machine to divide and shear the flat strip, and control the specification of the strip after dividing and shearing to be 1.2mm thick*width 39.9± 0.1mm.

[0040] The high-frequency quenching step: using a high-frequency quenching machine with a power of 75KW to conduct i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com