Patents

Literature

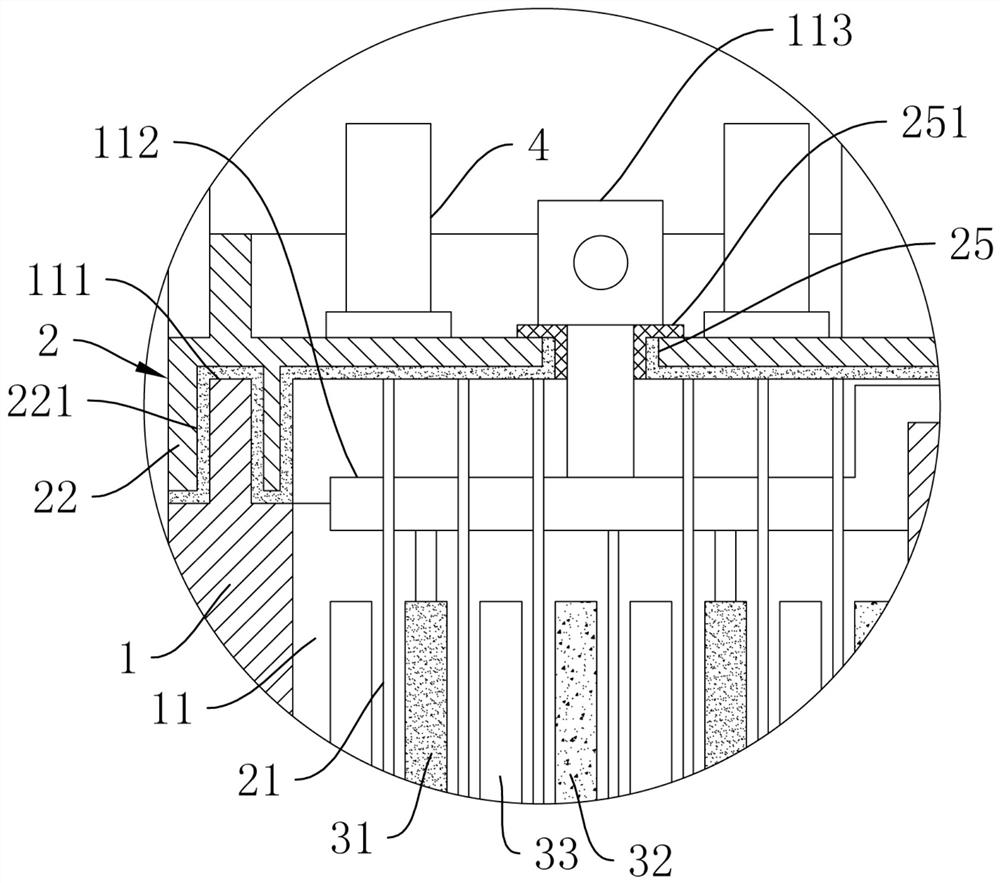

35results about How to "Guaranteed surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

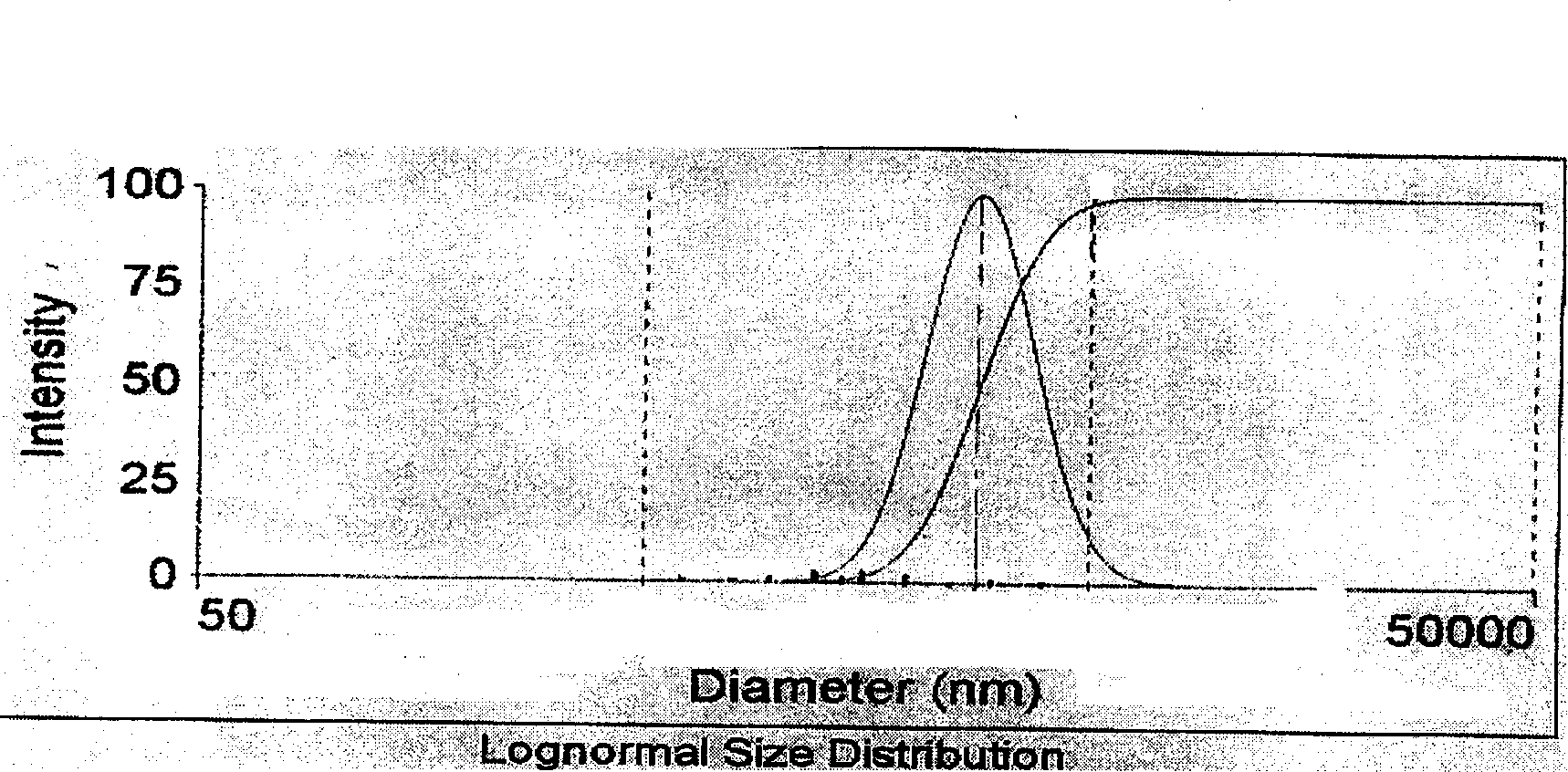

Prepn of super-paramagnetic polymer microsphere

InactiveCN1468898ASolving Dispersion ProblemsFix compatibility issuesInorganic pigment treatmentPolymer sciencePolyolefin

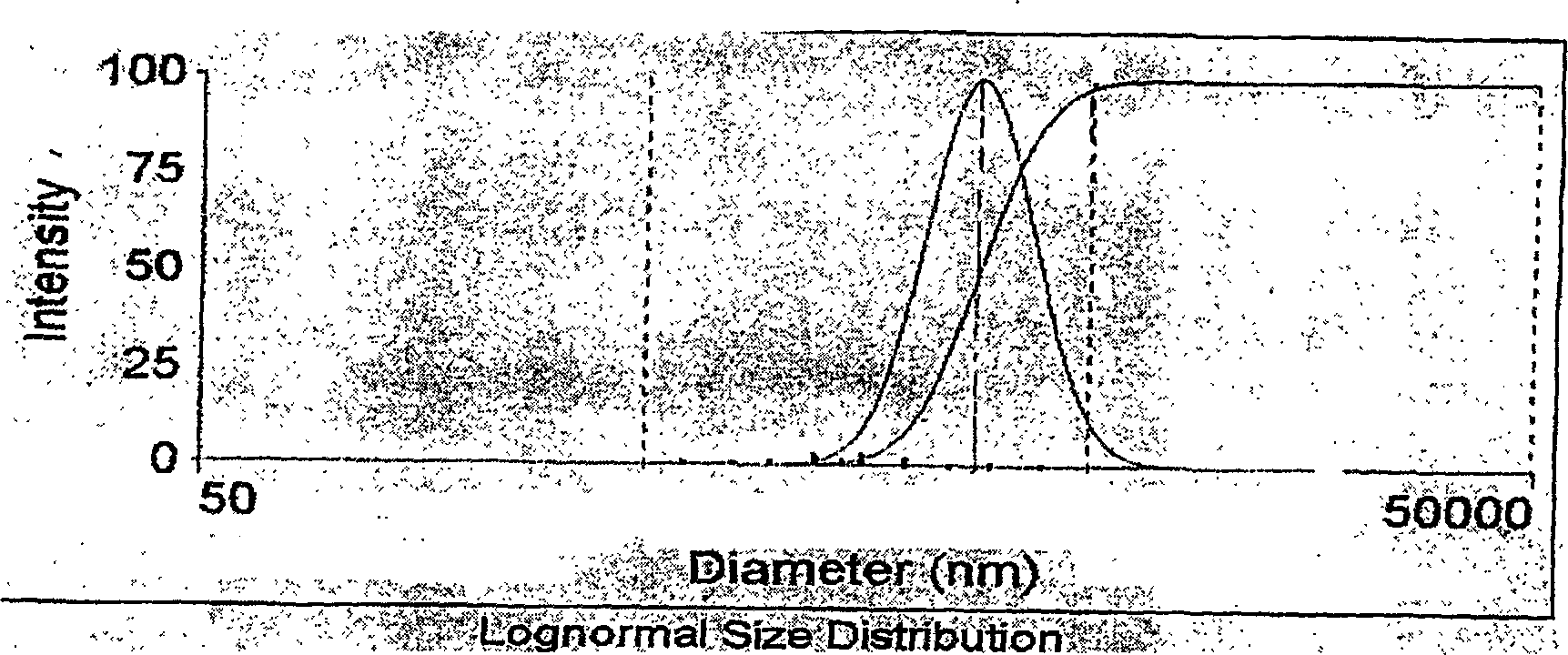

The present invention provides the preparation process of super-paramagnetic polymer microsphere. The super-paramagnetic polymer microsphere consists of polyolefin polymerized with lipophilic olefin monomer and organic monomer with hydrophilic functional radical and coated nano magnetic grains of modified ferroferric oxide. The nano magnetic grains with one surface lipophilic layer can be well dispersed in organic matter to form magnetic fluid and dispersed inside polymer microsphere to obtain super-paramagnetism. The microsphere is regular and has size of 0.1-5 micron and has magnetic ferroferric oxide accounting for 0.5-40 wt% of the whole micro microsphere. The present invention has the advantages of simple preparation process, narrow microsphere size, regular appearance, high functional radical content, homogeneous magnetism, stable chemical performance and acid and alkali resistance.

Owner:北京倍爱康生物技术有限公司 +1

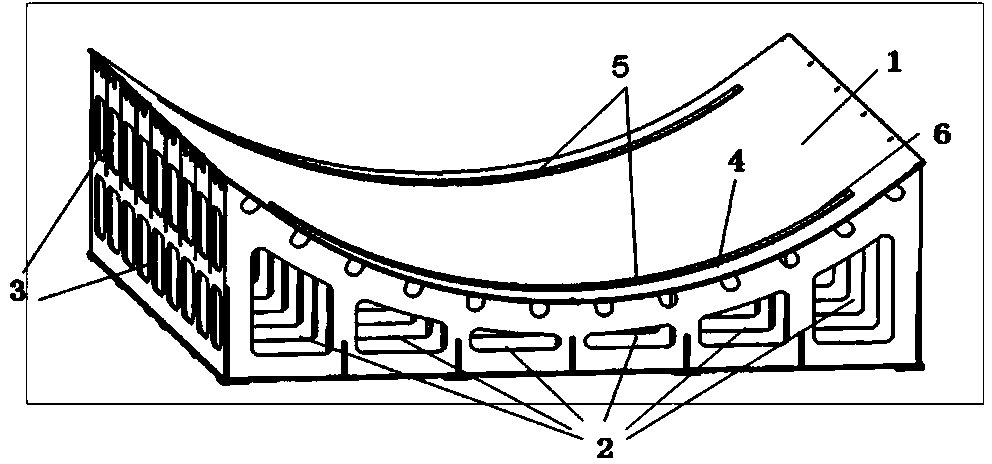

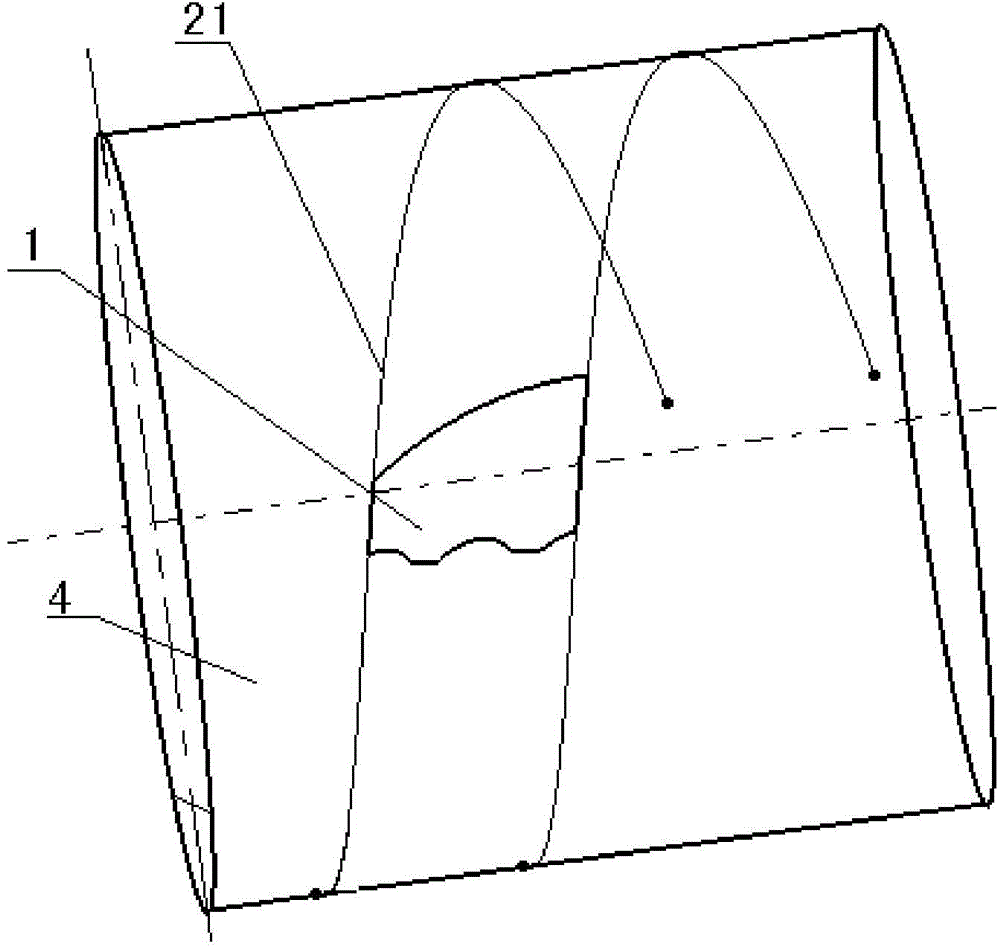

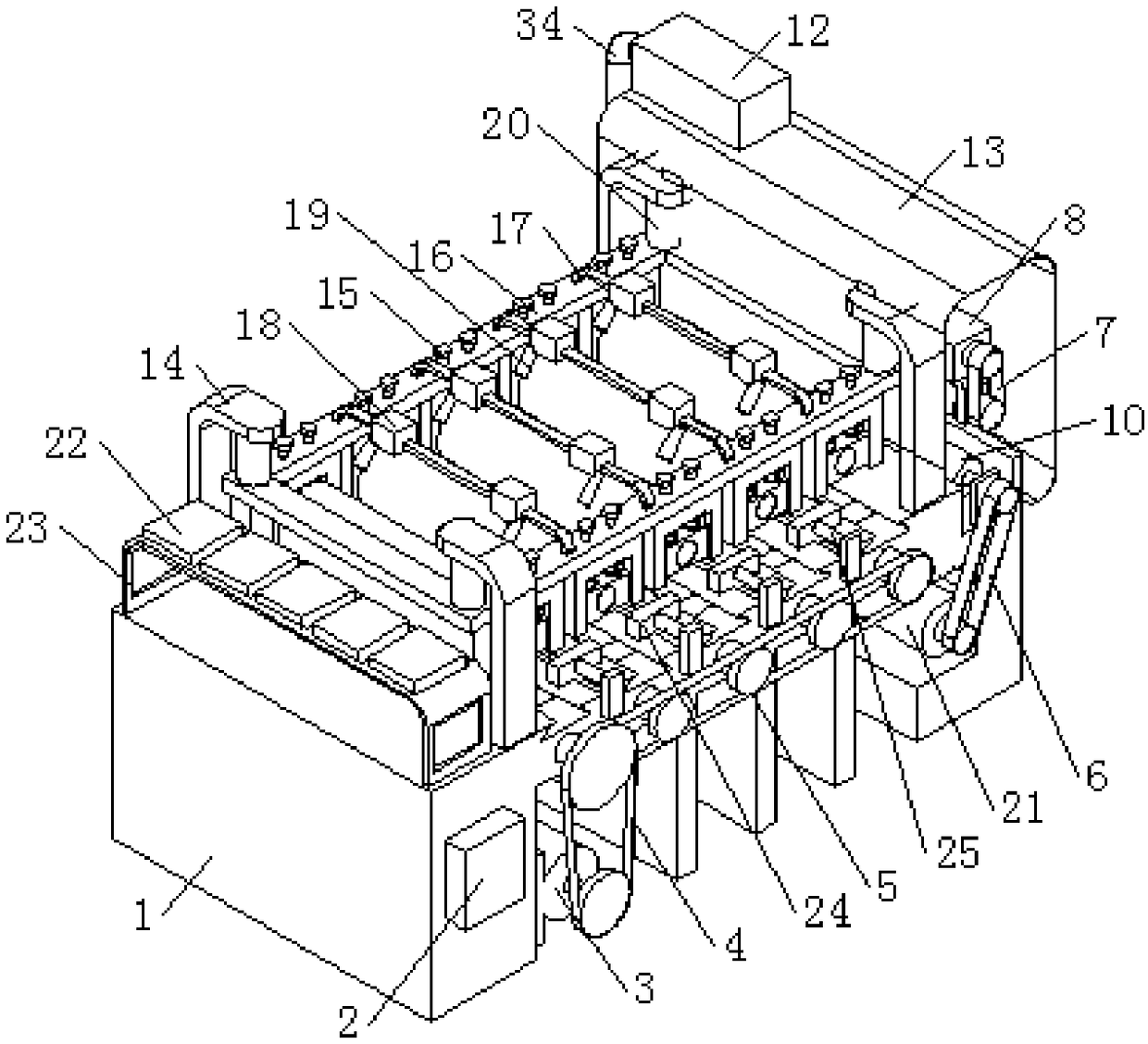

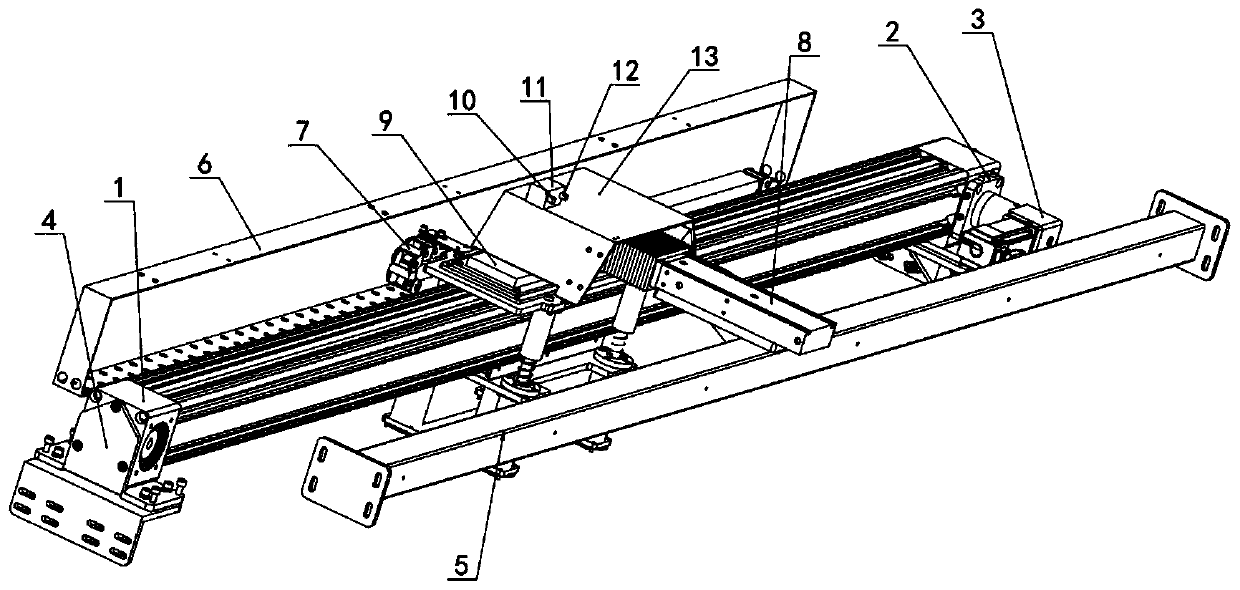

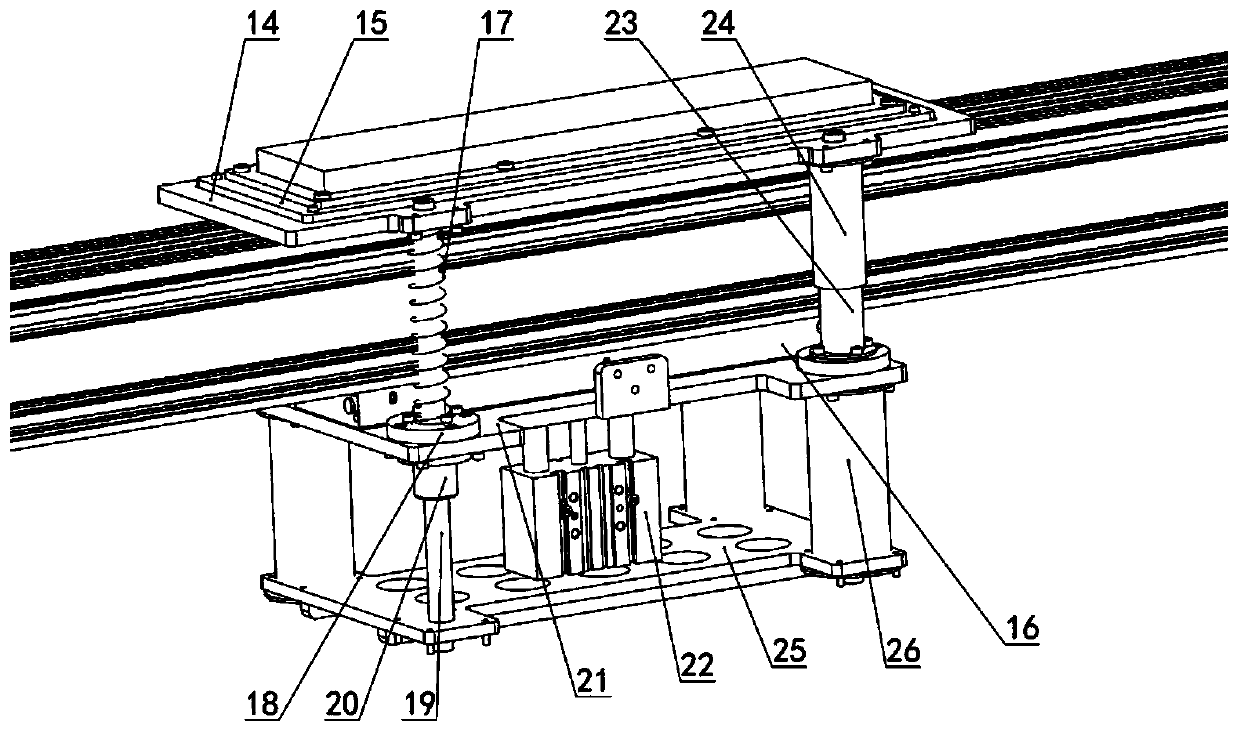

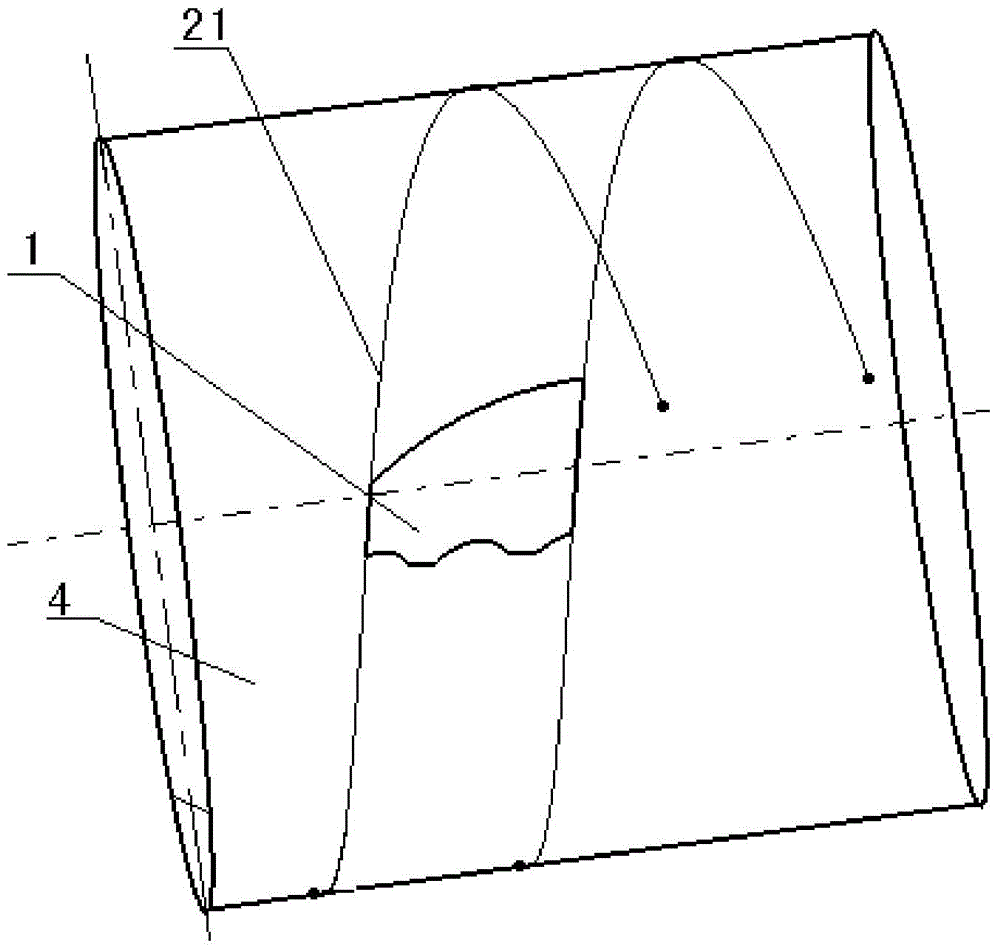

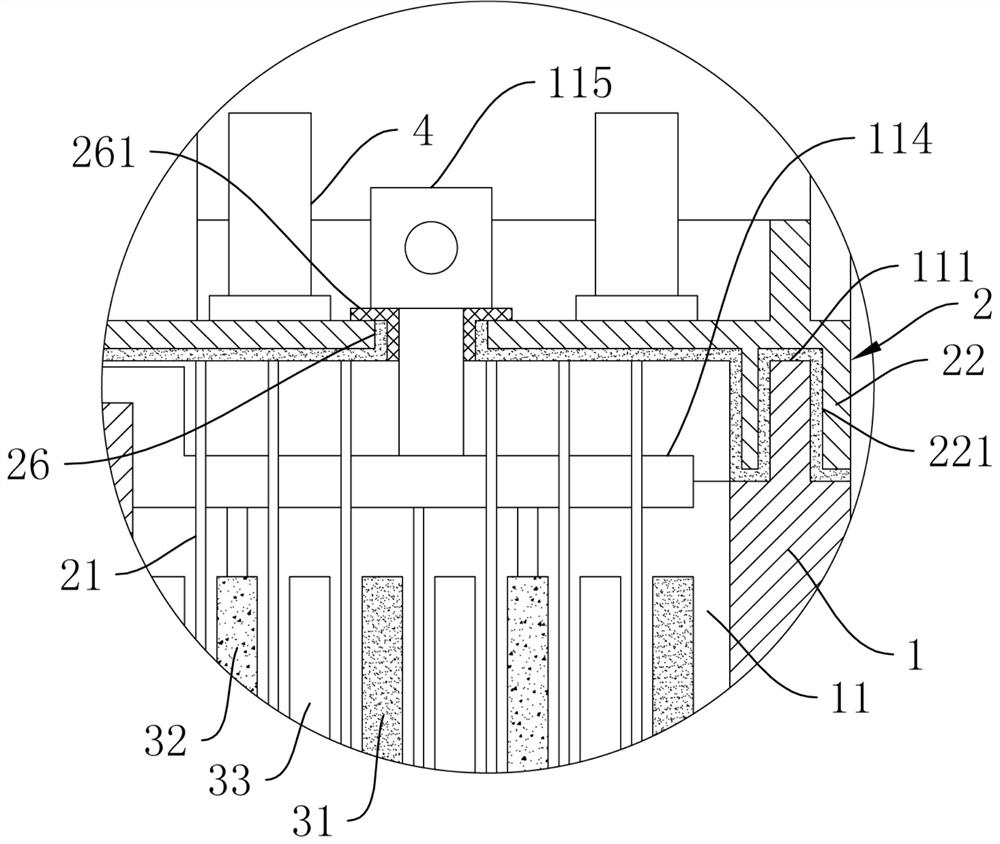

Preparation device of aircraft composite material fuselage wall panels and preparation method thereof

The invention belongs to the aerospace manufacturing technology, and relates to a preparation device of an aircraft composite material fuselage wall panels and a preparation method thereof. Cap-shaped stringers are formed through solid male molds; large opening frame type female molds are adopted to lay skins to form the wall panels; and cap-shaped stringer positioning tools are adopted to control gaps of the stringers so as to realize precise positioning of the cap-shaped stringers and to finish the production of the fuselage wall panels. In the preparation method of the aircraft composite material fuselage wall panels, the phenomenon of internal corner ester enrichment and external corner attenuation of the cap-shaped stringers can be effectively reduced by adopting an atmosphere feeding manner and a rubber soft mold process, so that the part thickness uniformity is improved; and one-way prepreg is required to be filled in cementing R areas in cementing assembly, and +- 45-degree laying layers are added, so that the stress concentration caused by the R areas, formed between the cap-shaped stringers and the skins, structurally bearing external loads can be relieved. Air bags in the cementing formation process are used as pressure transfer mediums in the cap-shaped stringers and cavities of the skins, and are capable of effectively guaranteeing the formation quality of the skins and cementing surfaces of the R areas.

Owner:AVIC COMPOSITES

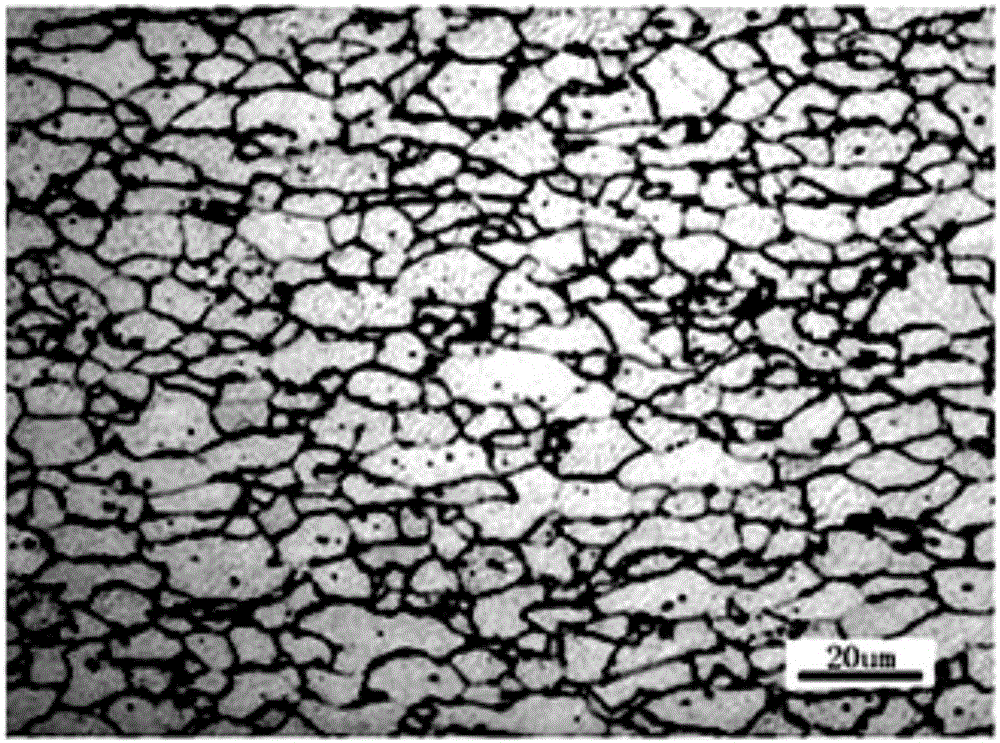

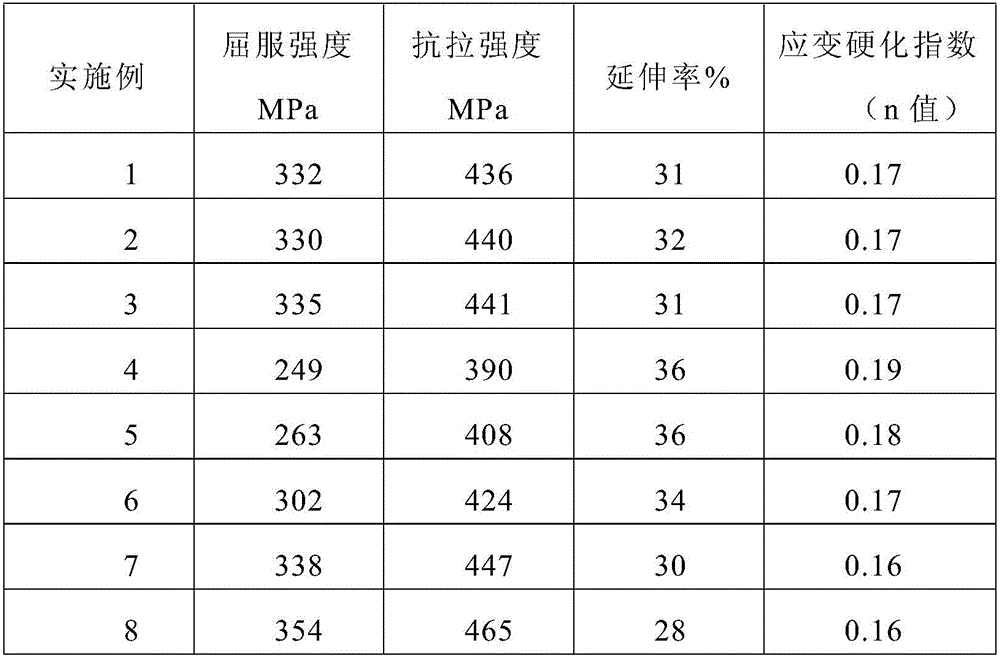

Cold-rolled low-alloy high-strength steel for automobiles and production method thereof

ActiveCN105925903AReduce the addition of precious metalsReduce manufacturing costHot-dipping/immersion processesHigh intensityPrecious metal

The invention discloses cold-rolled low-alloy high-strength steel for automobiles and a production method thereof, and belongs to the technical field of metal material. The high-strength steel is composed of, by weight, 0.05-0.08% of C, Si smaller than or equal to 0.05%, Mn smaller than or equal to 0.5%, P smaller than or equal to 0.025%, S smaller than or equal to 0.01%, 0.010-0.025% of Nb, 0.015-0.050% of Al, N smaller than or equal to 0.003% and the balance Fe and inevitable impurities. According to the production method, the high-strength steel low in cost and high in quality are produced through the sequential steps of blast furnace iron melting, molten iron desulphurization, converter smelting, RH vacuum treatment, continuous casting, conventional hot rolling, acid pickling and cold continuous rolling, continuous annealing, flattening and drawing-straightening. According to the steel and the production method thereof, the cost is low, addition of precious metal is reduced compared with the traditional technology, the hot rolling and coiling temperature is controlled according to thickness, and the uniformity and the stability of the mechanical property of cold-rolled sheets different in thickness specification are realized.

Owner:武汉钢铁有限公司

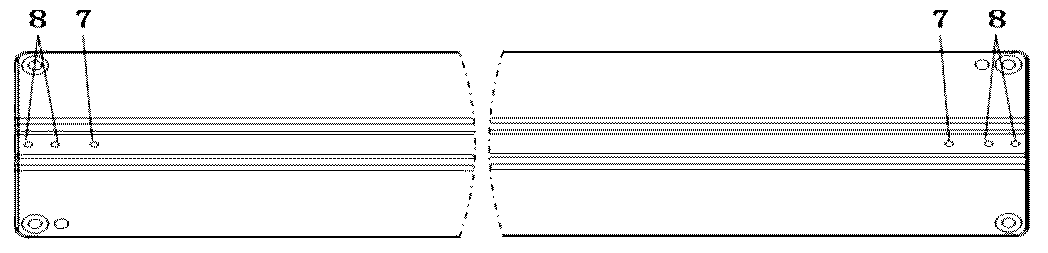

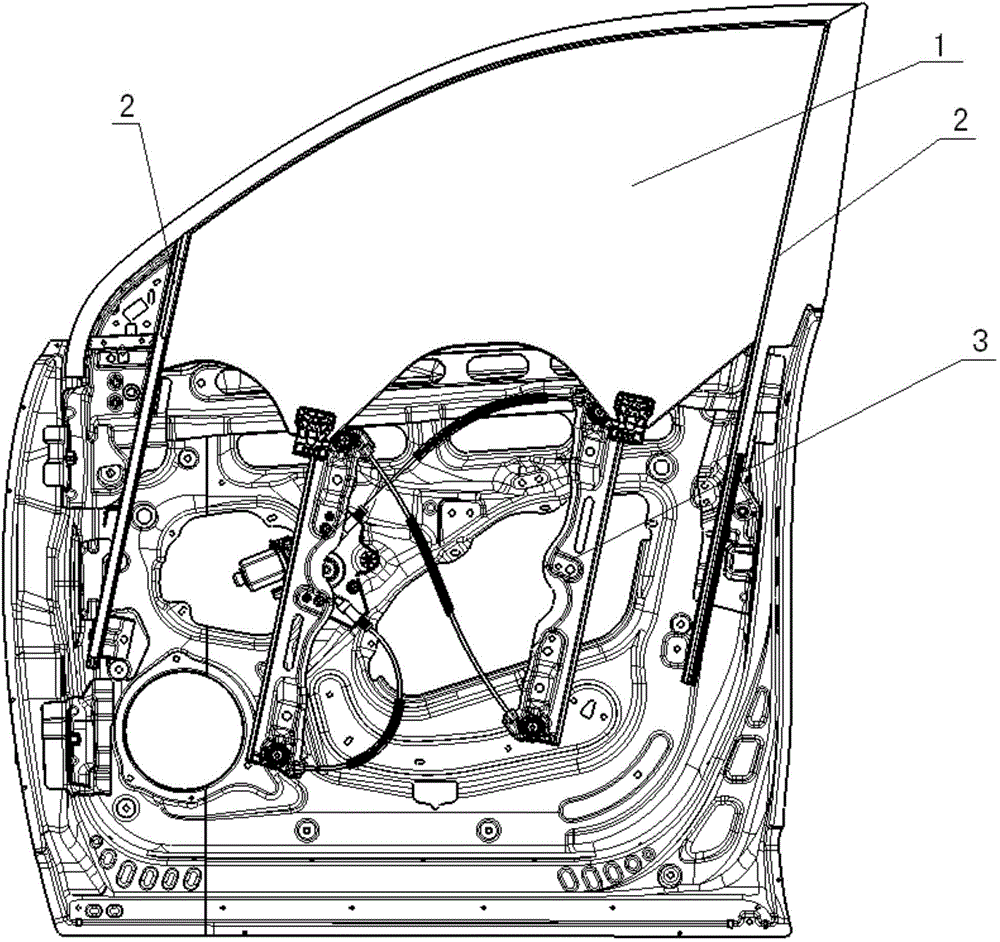

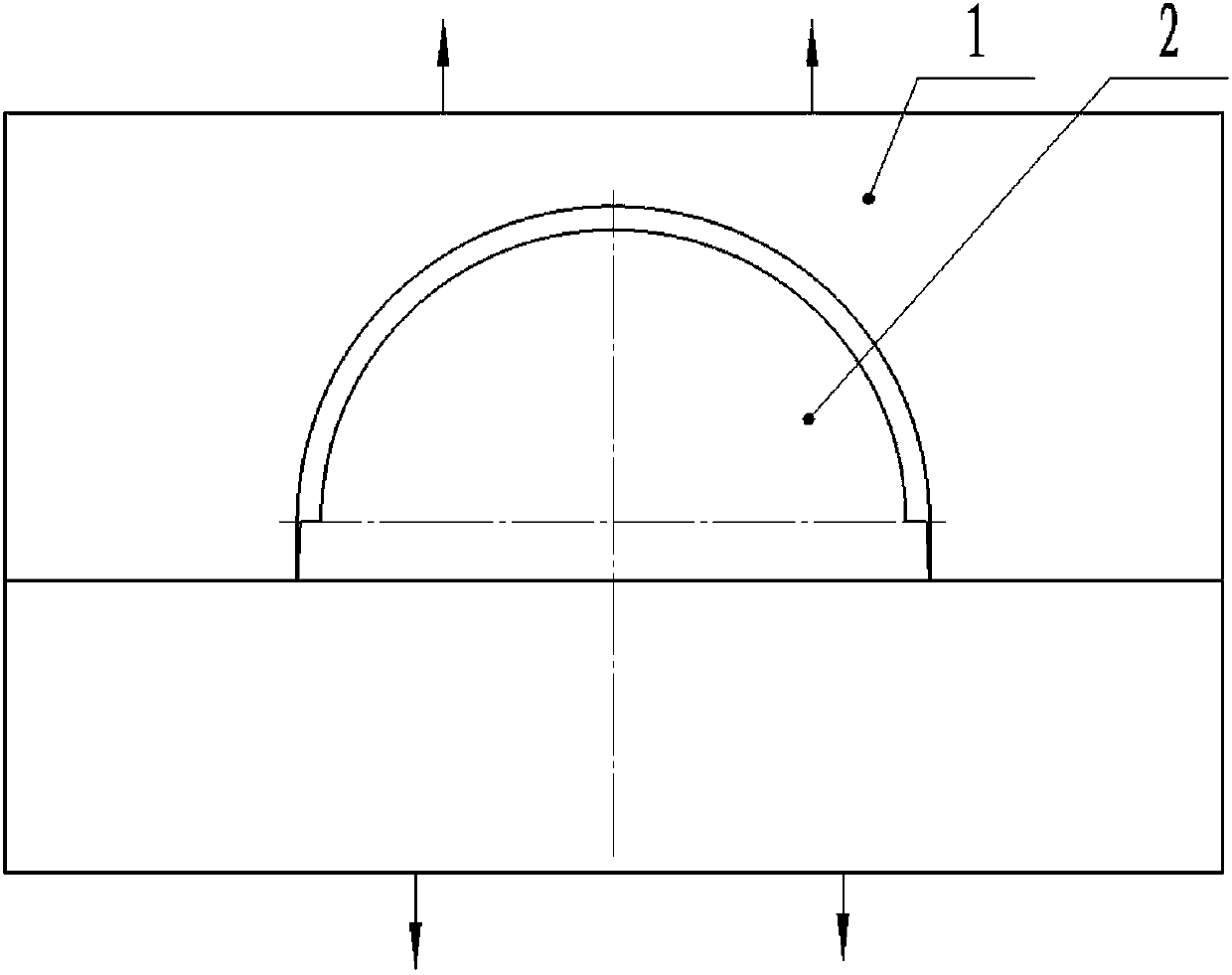

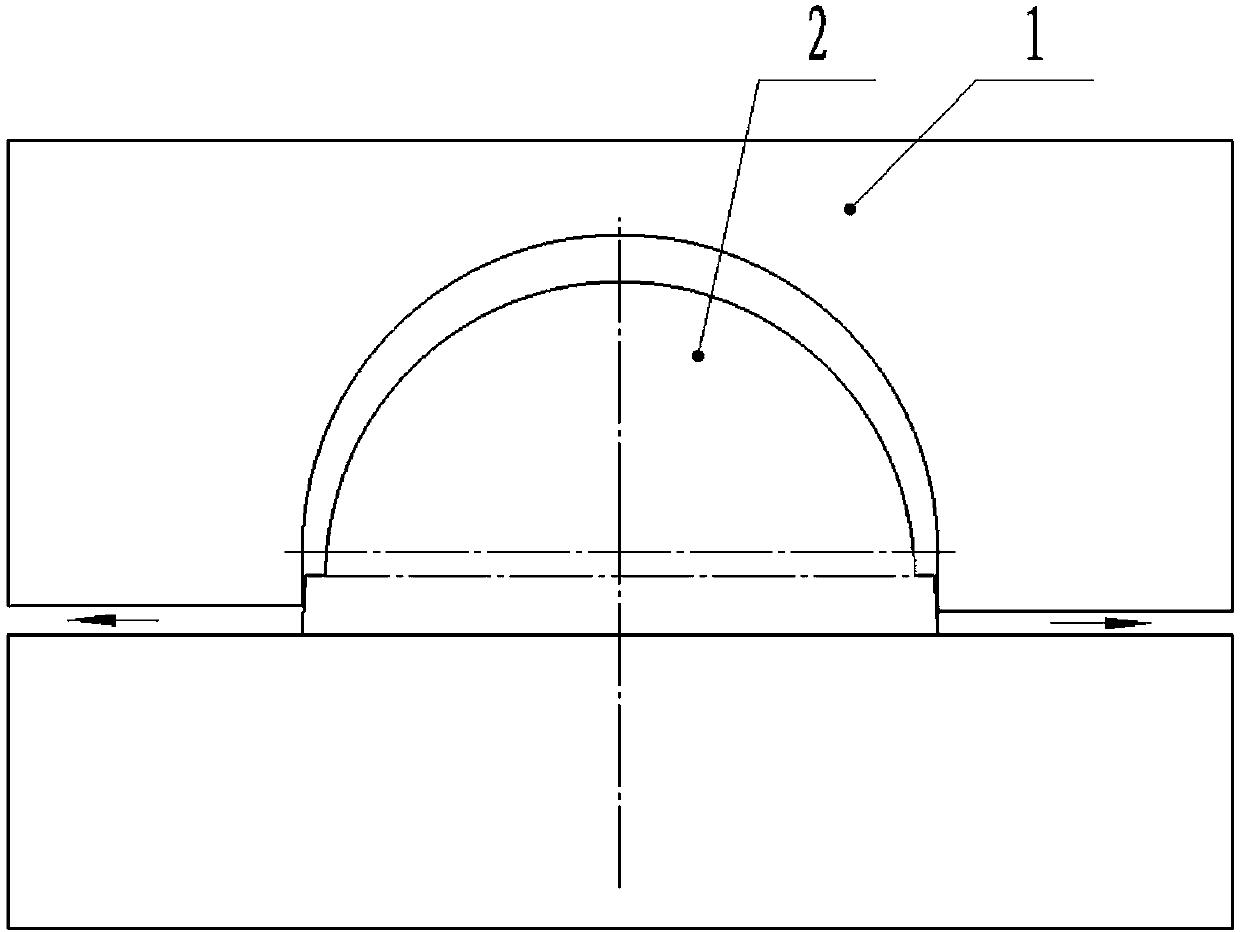

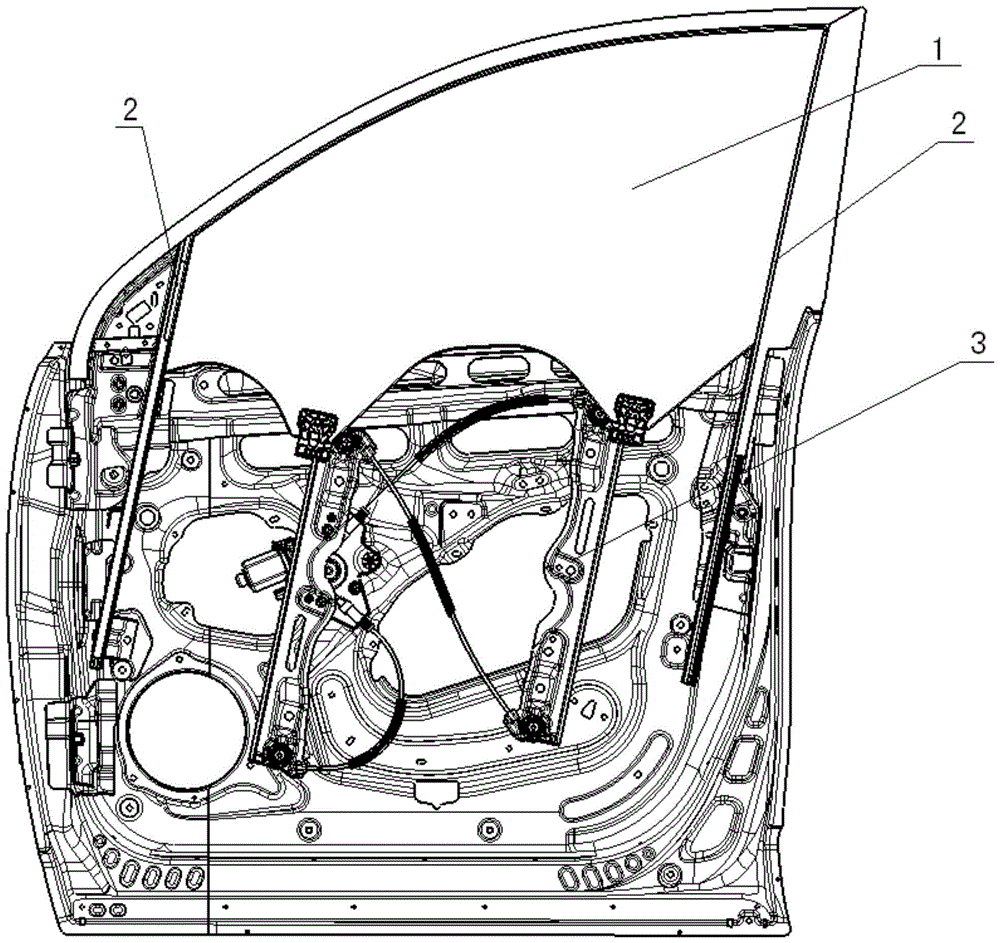

Window glass lifting system

ActiveCN104612547AImprove comfortGuaranteed surfacePower-operated mechanismWing arrangementsFace structureElectrical and Electronics engineering

The invention discloses a window glass lifting system. The window glass lifting system comprises window glass, a glass lifter and two parallel guide rails. According to the window glass lifting system, the window glass is arranged between the two parallel guide rails, the window glass is designed to be of a curved face structure, meanwhile the trajectories of the guide rails are curves, and the trajectories of the guide rails and the window glass are located on the same curved face, so that it is guaranteed that the window glass of the curved face structure is attractive in modeling, the requirements for automobile profile and comfort of modern people are met, meanwhile the bent gradient of the window glass is matched with the guide rails on the two sides of the window glass, the window glass can be made to slide smoothly in the two parallel guide rails under the pushing action of the glass lifter, the phenomena that it is difficult for the window glass to lift, the window glass is stuck, the guide rails are worn, and a window generates noises due to guide rail deviation between the window glass and the guide rails are avoided, and the comfort in using of the window is improved.

Owner:CHERY AUTOMOBILE CO LTD

Technique for casting gray cast iron thin-wall pipe fitting evanescent die

InactiveCN103418746AGuarantee product qualityUniform densityFoundry mouldsFoundry coresVacuum assistedPipe fitting

The invention relates to the field of casting evanescent dies, in particular to the technique for casting a gray cast iron thin-wall pipe fitting evanescent die. The purpose that the technique for casting the evanescent die is applied to the field of gray cast iron thin-wall pipe fitting production is achieved. The technique for casting the gray cast iron thin-wall pipe fitting evanescent die comprises the steps of bead pre-foaming, die manufacturing and forming, white die drying and bonding, coating, drying, encasing, vacuum-assist pouring and out-casing and grinding. The die manufacturing and forming comprises that the steps of operating a make-up machine to close the die, filling a model of the make-up machine with EPS beads obtained in the step of bead pre-foaming, filling the model of the make-up machine with steam, cured EPS beads and the formed white die, filling the model of the make-up machine with cooling water to be cooled and operating the make-up machine to open the die and taking out the white die. The technique is improved reasonably, the defect of caliber of a gray cast iron thin-wall pipe fitting can be effectively avoided, the quality of the gray cast iron thin-wall pipe fitting is improved, and the technique is suitable for being used for manufacturing a high-precision and high-quality gray cast iron thin-wall pipe fitting.

Owner:阳城县华王通用离心铸管厂 +1

Production of phi-0.1 cored lead-free soldering wire

ActiveCN101073865AImprove compactnessGuaranteed surfaceDrawing diesExtrusion control devicesSolderingLanthanum

The invention is concerned with the manufacture method for core non-plumbum tin wire with 0.1mm diameter, it is: the alloy of tin, silver, copper and lanthanum, that the content is silver 0.1 - 4.0%, copper 0.2-2.2%, lanthanum 0.01-0.5%, and tin is surplus, and flux is extrusion to the core non-plumbum tin wire with 6.0mm - 12.0mm diameter by over 350 ton oil-hydraulic press, pulls the core non-plumbum tin wire with 6.0mm - 12.0mm diameter to core non-plumbum tin wire with 0.6mm diameter, uses crude diamond model allotype that is 66 moulds to pull to be the core non-plumbum tin wire with 0.1mm diameter, uses the mould under D group to pull for two hours then changes the mould that can be used by wash three times after changing by kerosene, cools 25 - 30 minutes for each pull wires then pull it again.

Owner:昆山成利焊锡制造有限公司

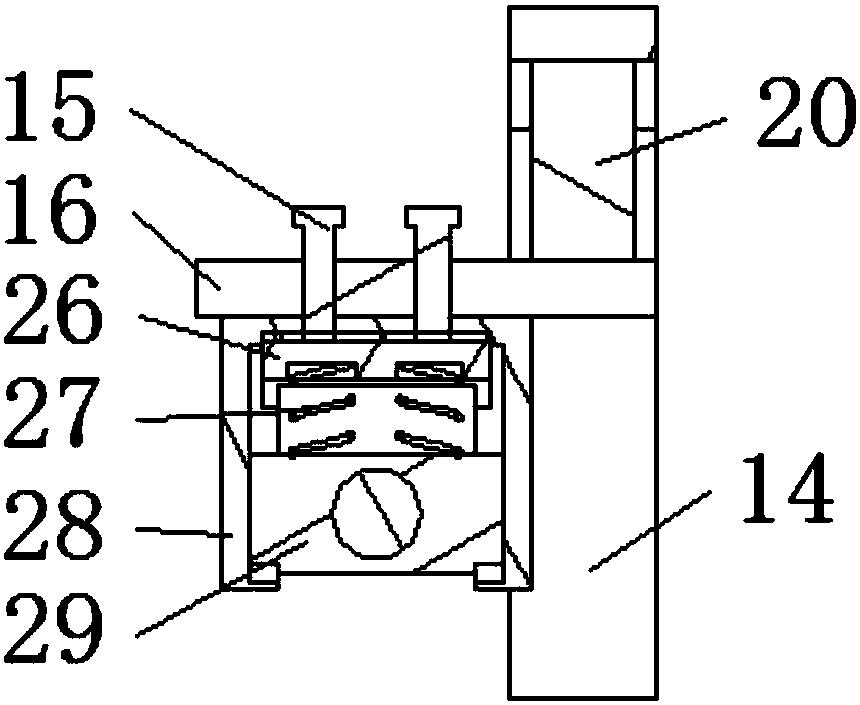

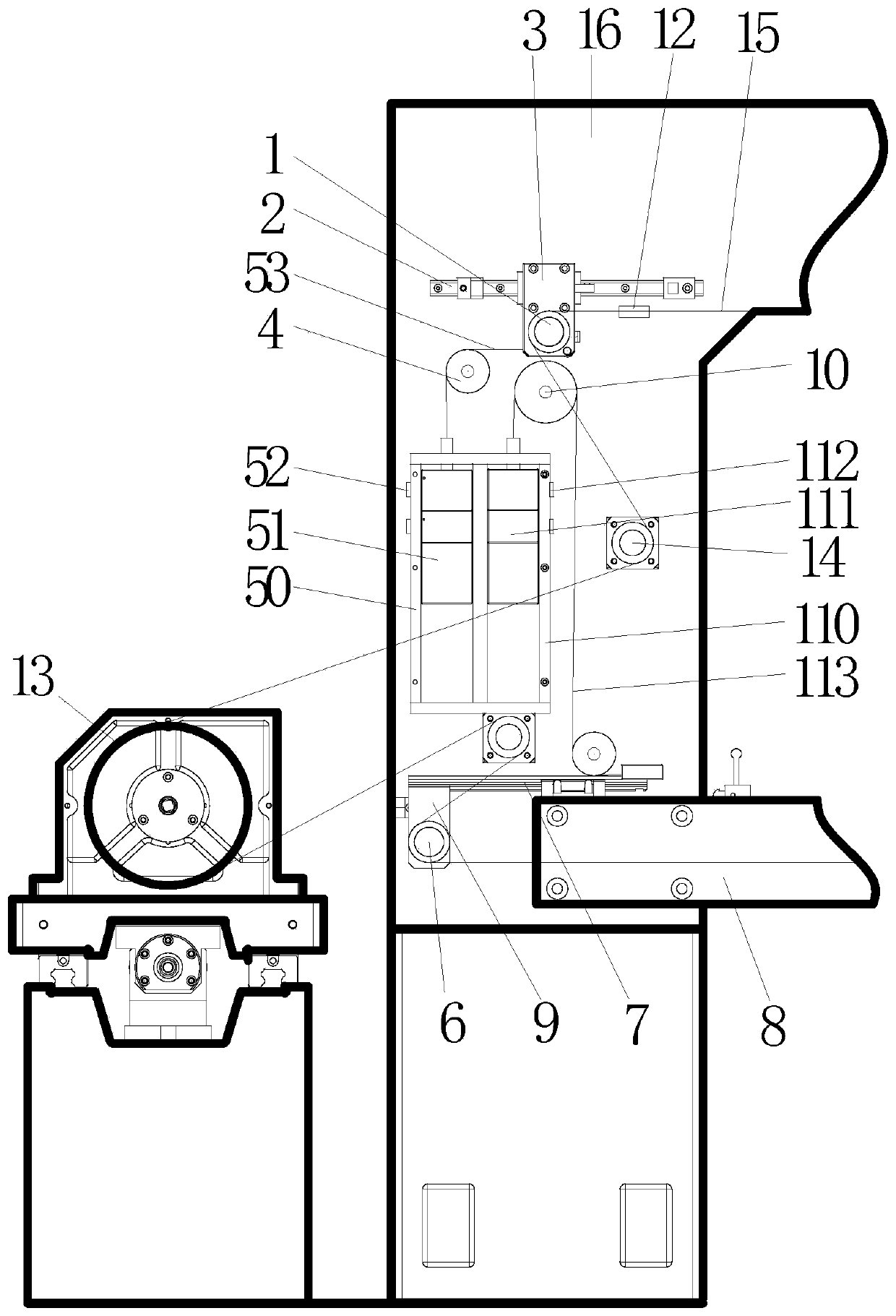

Cleaning device of polishing pad finishing disc

ActiveCN104416462AGuaranteed surfaceGuaranteed cleanlinessCleaning using toolsAbrasive surface conditioning devicesEngineeringHigh pressure

The invention discloses a cleaning device of a polishing pad finishing disc. The cleaning device of the polishing pad finishing disc comprises a cleaning cup, a cleaning brush bearing device, a cleaning brush, a central spray nozzle, a first valve, a pure water power pipe, a driving shaft, a bearing, an air cylinder, a motor and a controller, wherein the cleaning brush is fixed onto the top surface of the cleaning brush bearing device; the upper end of the bearing is fixed onto the cleaning brush bearing device, and the lower end of the bearing is connected to the air cylinder; the air cylinder drives the bearing to move up and down; the driving shaft is provided with a through hole and fixedly pivoted into the bearing, the upper end of the driving shaft penetrates and extends out of the cleaning brush bearing device, and the lower end of the driving shaft is connected to the motor; the motor is fixed inside the bearing for driving the driving shaft to rotate; the central spray nozzle is fixed at the upper end of the driving shaft and communicated with the through hole of the driving shaft; the first valve is connected to the through hole between the lower end of the driving shaft and the pure water power pipe; the pure water power pipe is used for providing high-pressure deionized water; the controller is used for controlling the air cylinder, the motor and the first valve to work according to cleaning triggering signals and cleaning stopping signals. The cleaning device of the polishing and finishing disc can keep the surface of the polishing pad finishing disc clean.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Wood-grain wire drawing and gold lacquer painting technique

InactiveCN104722461AGuaranteed surfaceEasy to manufacturePolyurea/polyurethane coatingsSpecial surfacesLacquerWear resistant

The invention discloses a wood-grain wire drawing and gold lacquer painting technique. The technique includes the following steps: (1) cleaning, namely thinner to clean the surface of furniture, and polishing by using abrasive paper after drying; (2), closing, namely adopting a Didebao mixture, PU primer or clear top coat, and selecting a spraying mode or a manual brushing mode for closing; (3), filling, and polishing after drying; (4), spraying or manually brushing primer, wherein the primer is PE or PU primer, and waiting for drying; (5), filling, and polishing smooth after drying; (6), spraying or manually brushing primer, wherein the primer is PE or PU primer, and polishing smooth after drying; (7), spraying or manually brushing gold primer or silver primer, wherein the gold primer or the silver primer is formed by adding gold powder or silver powder in PU primer or PU top coat and mixing; (8), spraying color; (9), wire-drawing or color-wiping; (10), spraying clear top coat. The technique is convenient in manufacturing and short in solidification time, and paint is more wear-resistant and scratch-resistant than common paint and long in service life.

Owner:郭大宽

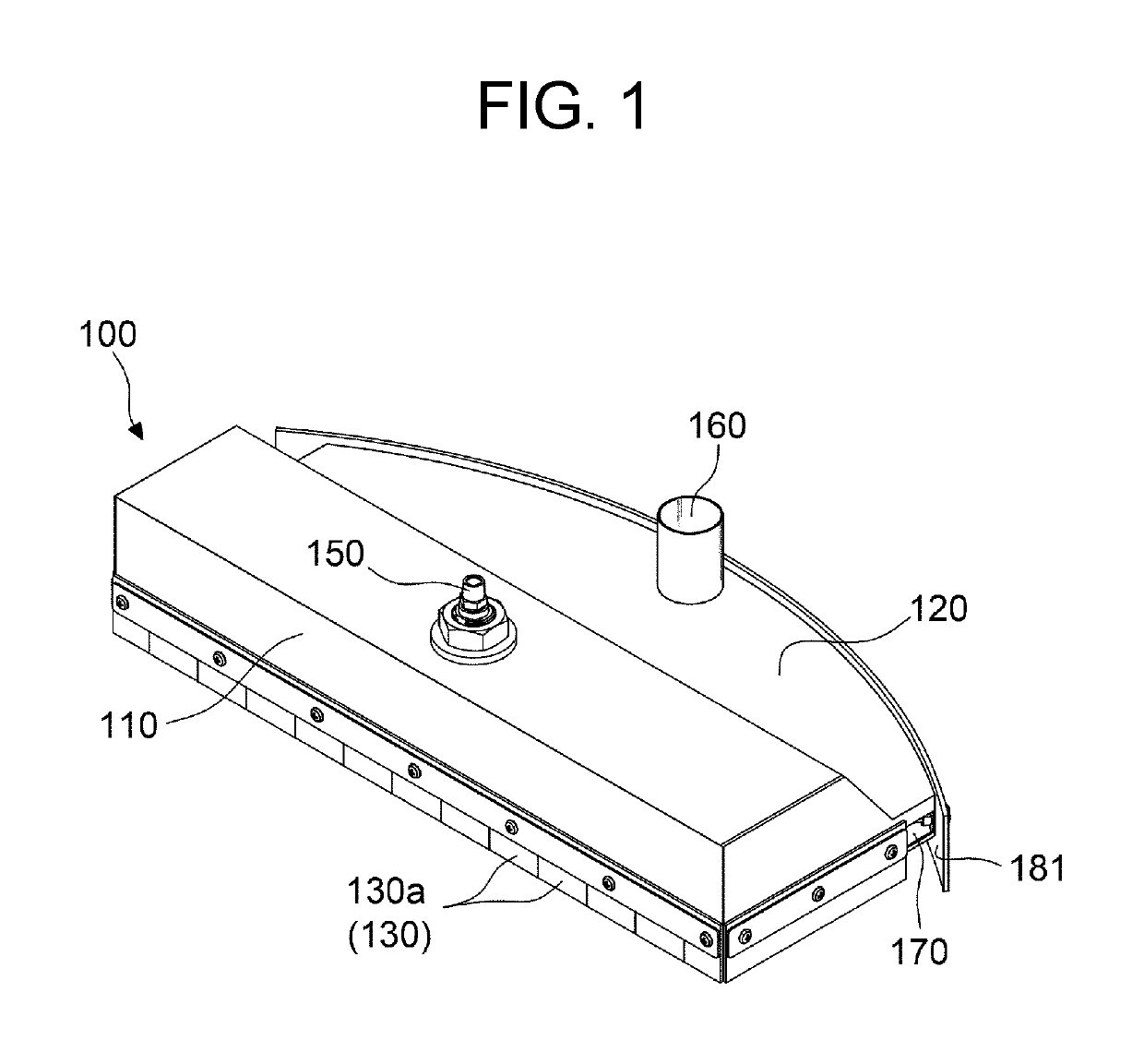

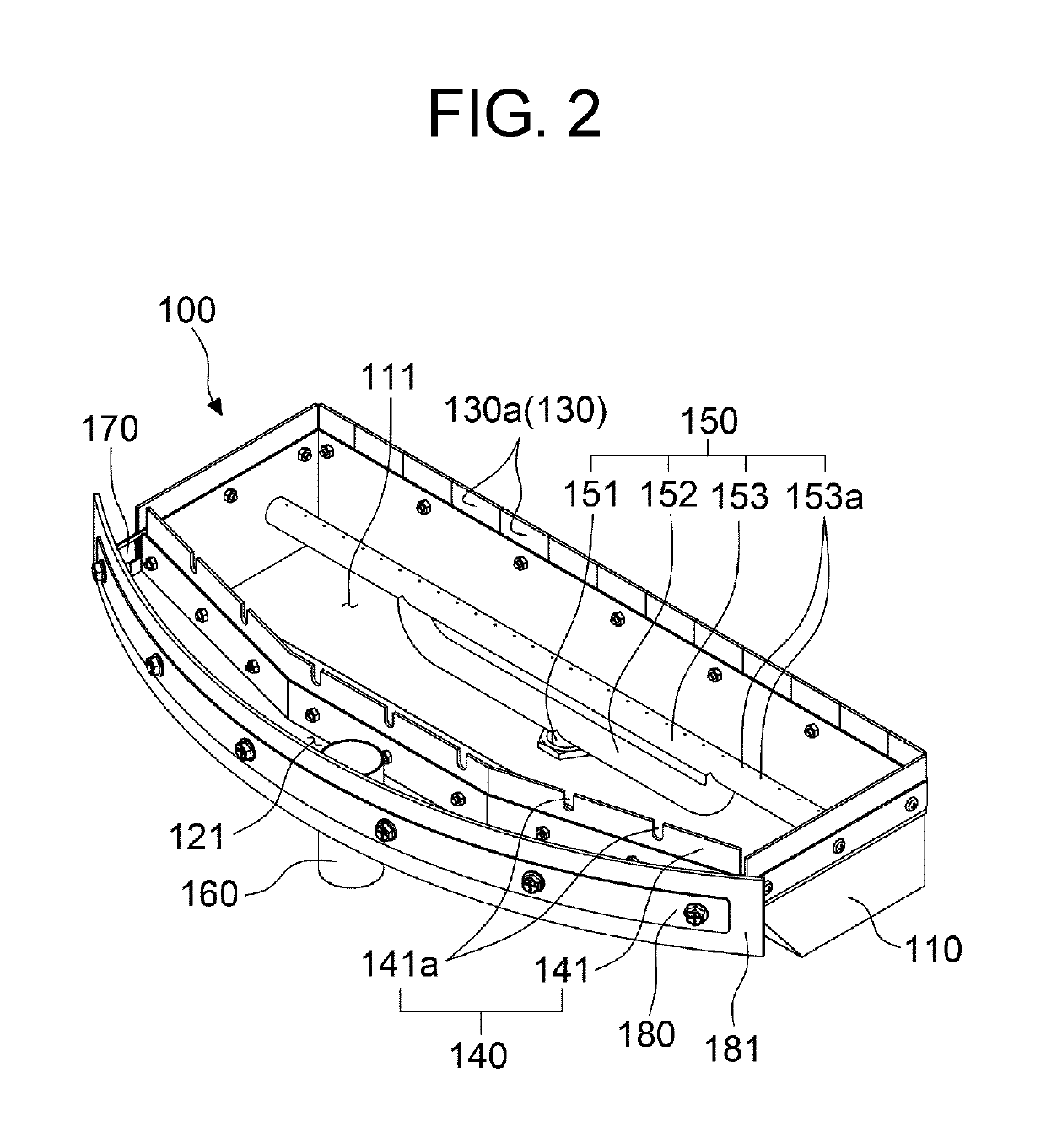

Conveyor belt cleaning apparatus

ActiveUS10266348B1Improve work efficiencyImprove productivityCleaningCleaning using toolsForeign matterEngineering

Provided is a conveyor belt cleaning apparatus, and particularly, to a steam conveyor belt cleaning apparatus which is installed above a conveyor belt and configured to remove foreign substances adhering to the conveyor belt. Provided is a structure of the cleaning apparatus capable of cleanly cleaning, sterilizing, and washing a surface of the conveyor belt by spraying steam to separate foreign substances attached to the surface of the conveyor belt, collecting the foreign substances in a direction toward a foreign substance discharge unit, discharging the foreign substances, and clearly removing the foreign substances. As described above, the cleaning apparatus for removing finely protruding residues, which are foreign substances adhering to the surface of the conveyor belt, and sterilizing and washing the surface of the conveyor belt, such that the surface of the conveyor belt may be cleanly maintained.

Owner:SJE

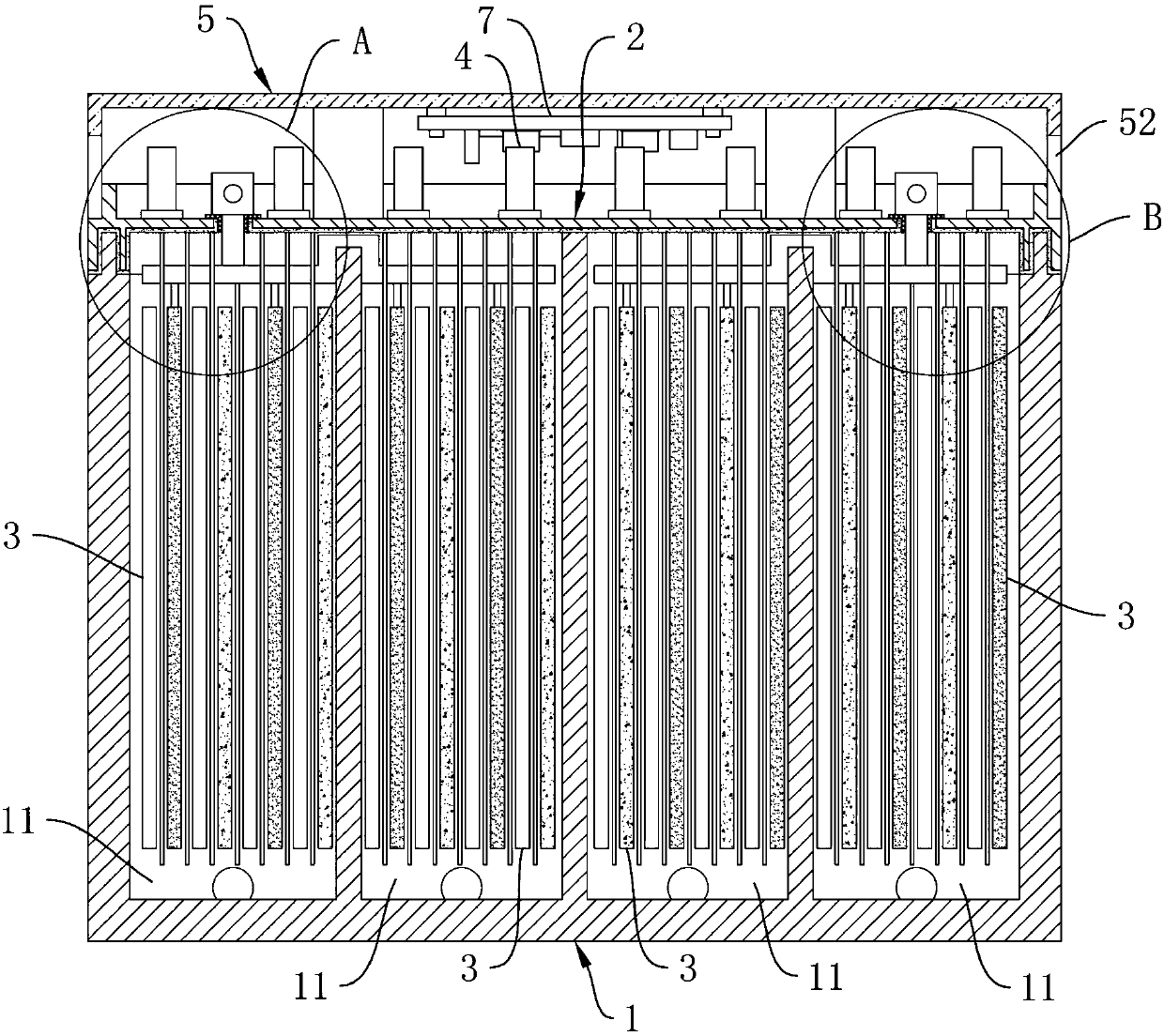

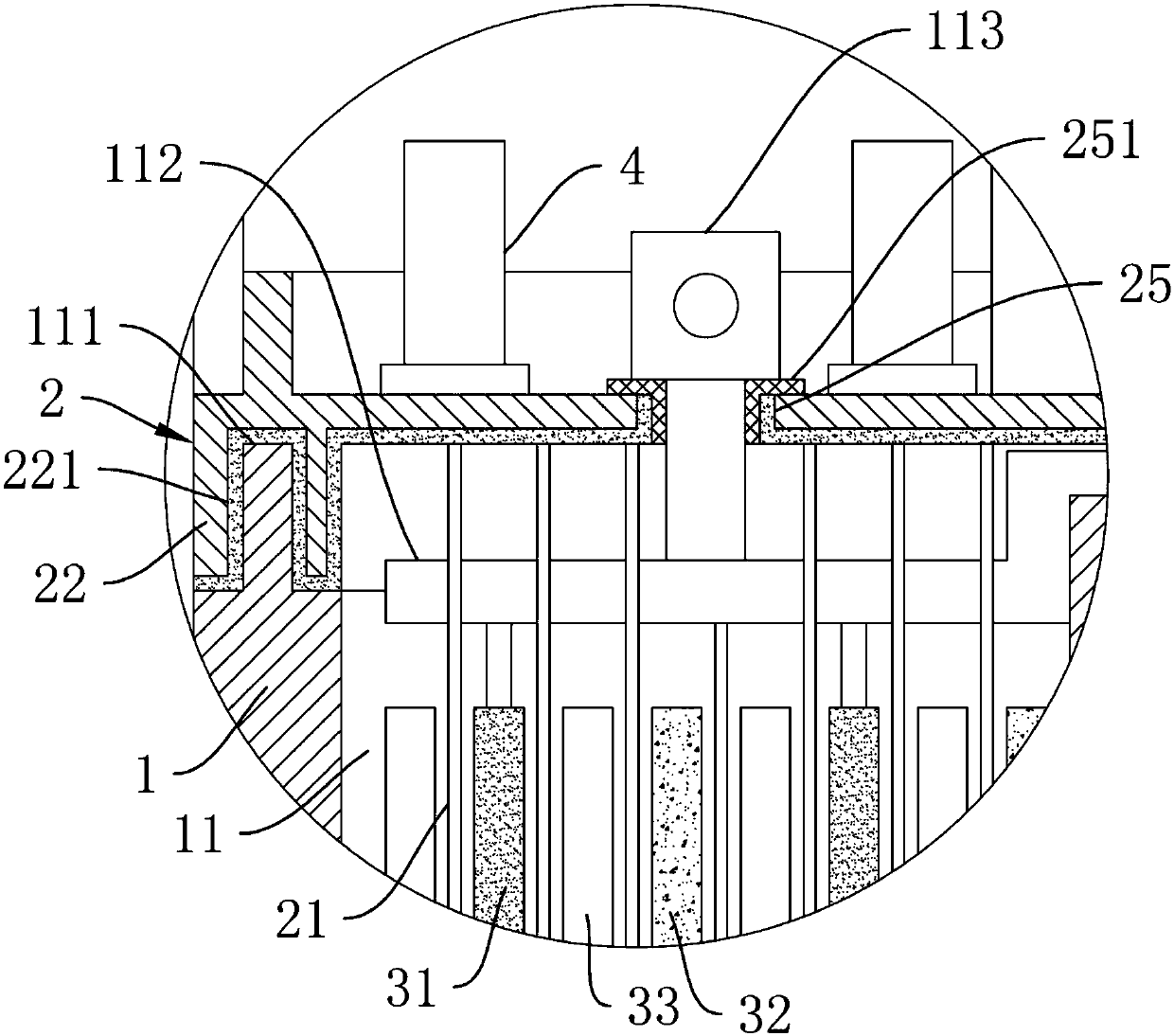

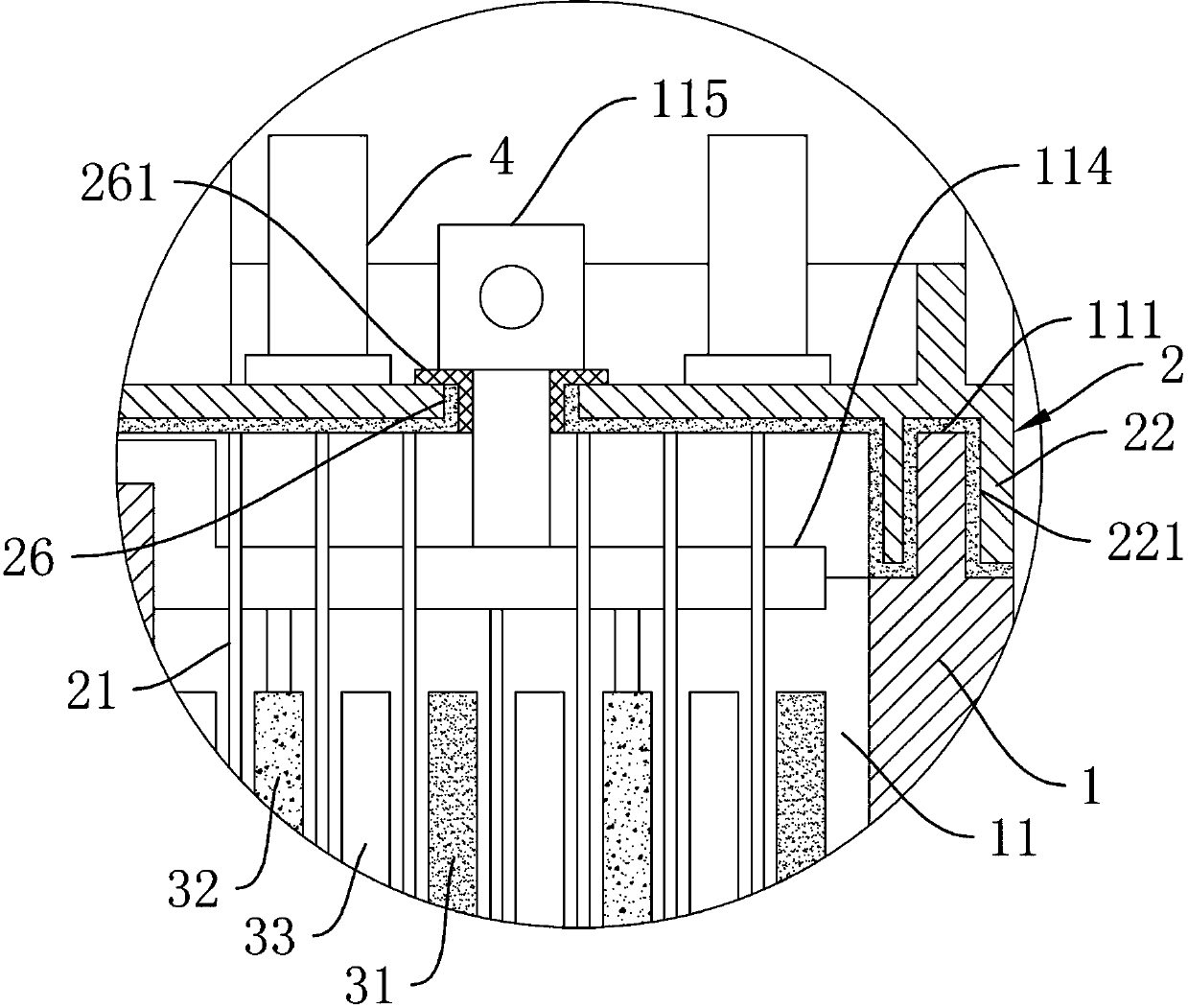

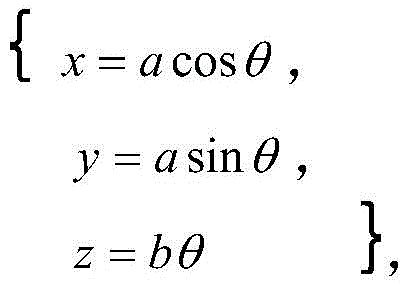

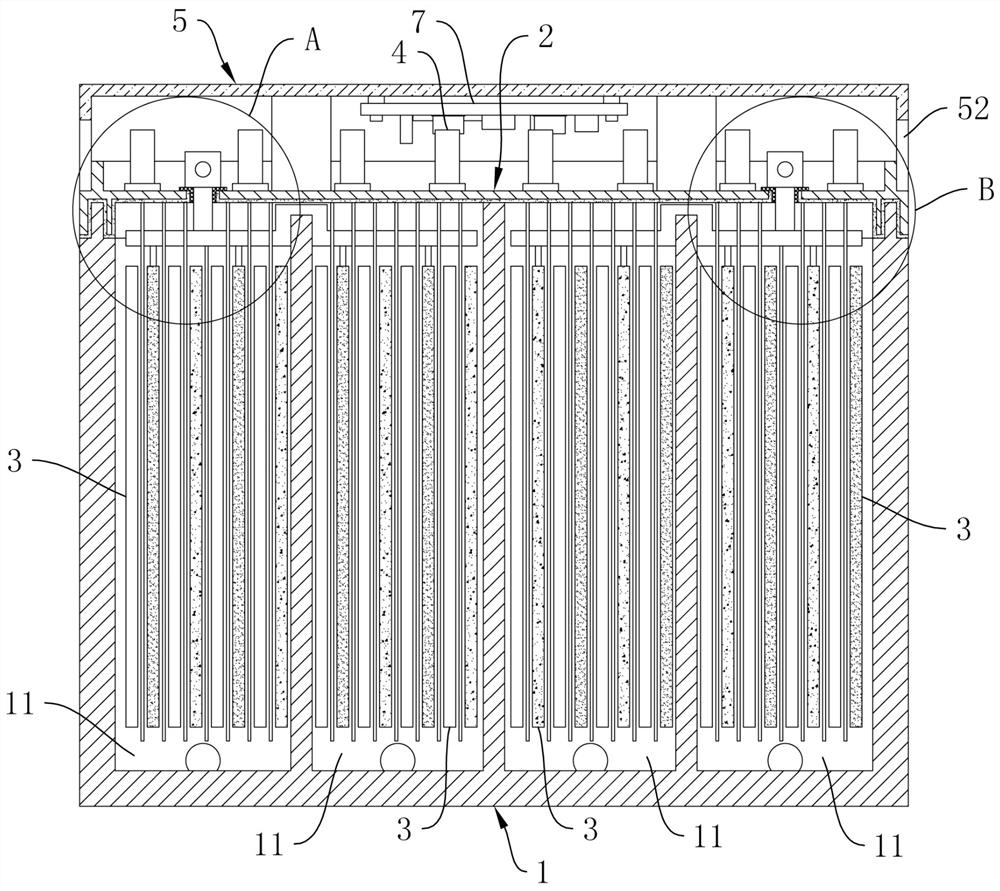

Ultrasonic lead-acid storage battery

ActiveCN110931891ADecay of power storage performanceThe storage performance is as stable as newFinal product manufactureElectrolyte/reactants regenerationElectrolytic agentElectrical battery

The invention relates to an ultrasonic lead-acid storage battery. The battery comprises a battery shell, a battery cover, a cluster group and at least one ultrasonic transducer, an accommodating cavity is formed in the top of the battery shell; a liquid outlet penetrating to the accommodating cavity is formed in the outer wall of the battery shell; a sealing plug is arranged in the liquid outlet;a plurality of insulating corrosion-resistant vibration strips are arranged at the bottom of the battery cover; the cluster group comprises a plurality of positive plates, a plurality of negative plates and a plurality of clapboards; the positive plates and the negative plates are stacked together in a staggered mode, the partition plates are arranged between the positive plates and the negative plates respectively, the cluster set is arranged in the containing cavity, the vibration strips are inserted between the positive plates and the partition plates and between the negative plates and thepartition plates respectively, and the ultrasonic transducer is arranged on the top face of the battery cover. Lead sulfate crystals on the surface of the battery plate are prevented by utilizing high-frequency ultrasonic oscillation, so that the battery plate is in full and comprehensive contact with an electrolyte, the attenuation of the electric power storage performance of the storage batterycan be greatly relieved, and the service life of the storage battery is prolonged.

Owner:彭志军

Paint technology method of furniture

InactiveCN103212525AGuaranteed surfaceEasy to manufacturePretreated surfacesCoatingsSurface cleaningEngineering

The invention discloses a paint technology method of furniture. The paint technology method comprises the following steps of: (1) thermally treating the surface of the furniture so as to fully evaporate moisture in the furniture; (2) carrying out fabrication processing on the surface of the furniture; (3) uniformly spraying varnish on the surface of the furniture and waiting for drying; (4) grinding, polishing and cleaning the surface; (5) spraying polyurethane primer on the surface of the furniture, and waiting for drying and curing; (6) processing the surface of the furniture, and waiting for drying and curing; and (7) producing a pattern on the surface so as to be more artistic, and carrying out cleaning treatment on the surface. According to the paint technology method, provided by the invention, produced paint has the advantages of convenience for production, quick curing time, low cost, long-time storage, large-scale production, stronger wear resistance and scratch resistance than common paint, long service life, and capability of effectively protecting the surface of the furniture.

Owner:NINGBO ZHENHAI JIAHUI INTPROP SERVICE

Power wiring pipe

The invention provides a power wiring pipe, which adopts split connection. The power wiring pipe comprises movably-connected fixing pipes for fixing a line and a connection pipe connecting the two fixing pipes, wherein the connection pipe and the fixing pipes are in threaded connection; one end of the fixing pipe has a conical structure, the inner wall of the conical structure is provided with a clamping tongue, and the other end is provided with multiple fixing devices; a round cover plate and the fixing pipe are in movable connection; the inner diameter of an annular cover is consistent withthe maximum inner diameter of the fixing pipe, and the inner wall is provided with a rubber dustproof plate. The power wiring pipe has the advantages of light weight, simple structure, good sealing performance and the like.

Owner:国网山东省电力公司青岛市黄岛区供电公司

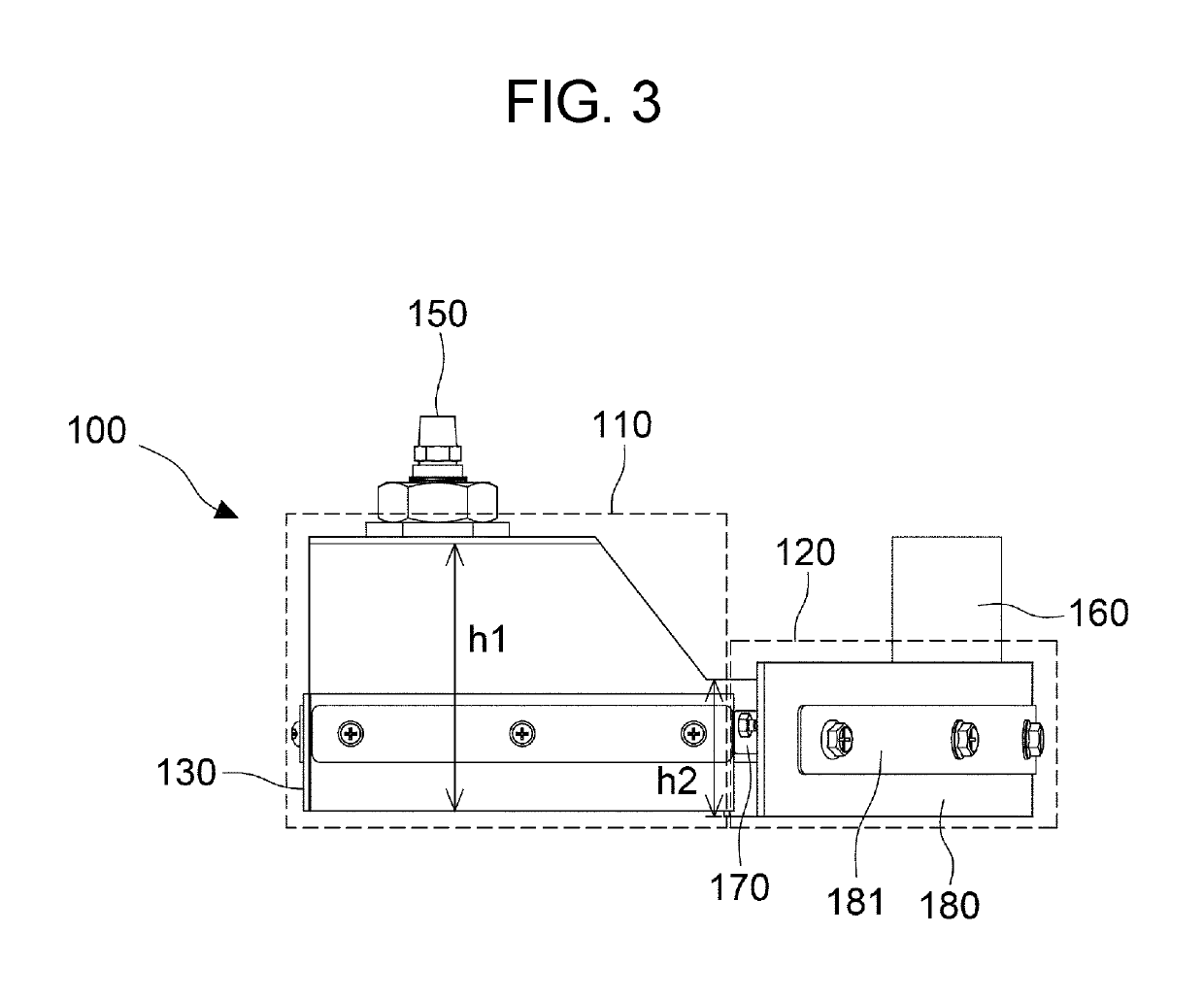

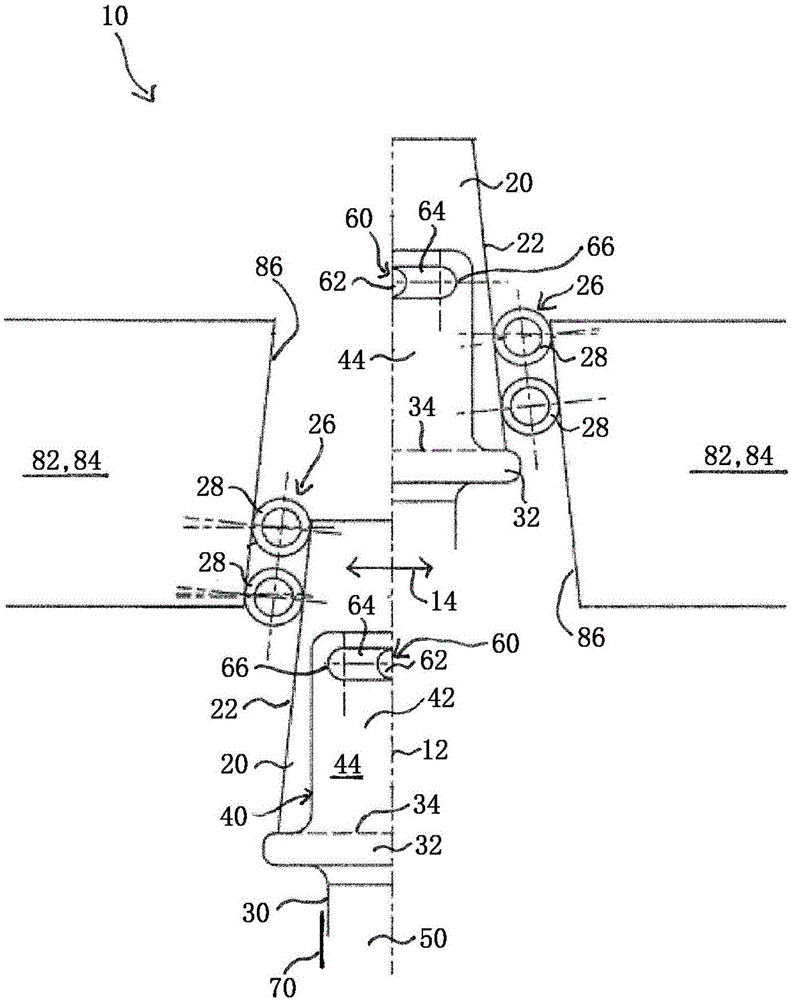

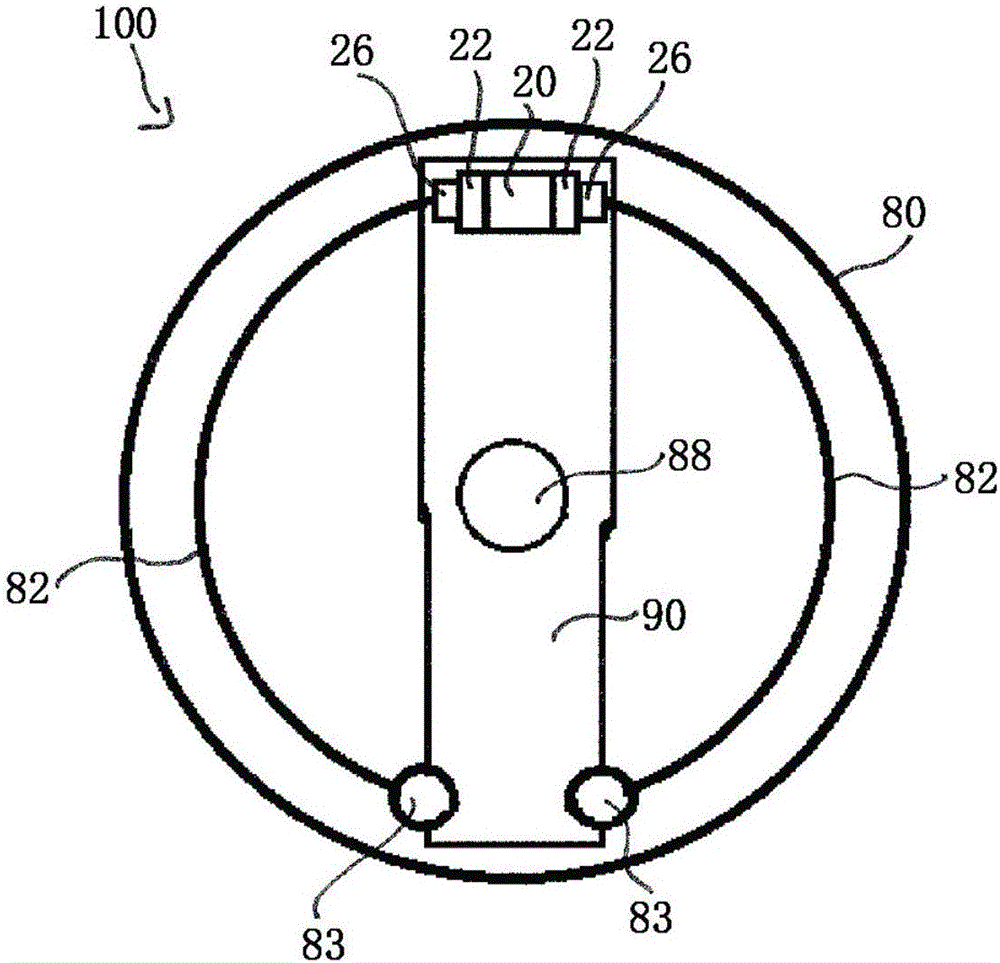

Wedge unit and braking device

InactiveCN106715946AExclude or prevent oblique positioningExclude or prevent angle changesBrake actuating mechanismsActuatorsEngineeringMechanical engineering

The invention relates to a wedge unit for a braking device (100) with brake pad supports (82), comprising a wedge (20) which can be moved along in a direction of actuation (12), for separating the brake pad supports (82), characterised in that an actuating element (30) for moving the wedge (20) is provided and that said wedge (20) is arranged such that it can move relative to the actuating element (30).

Owner:SAF HOLLAND GMBH

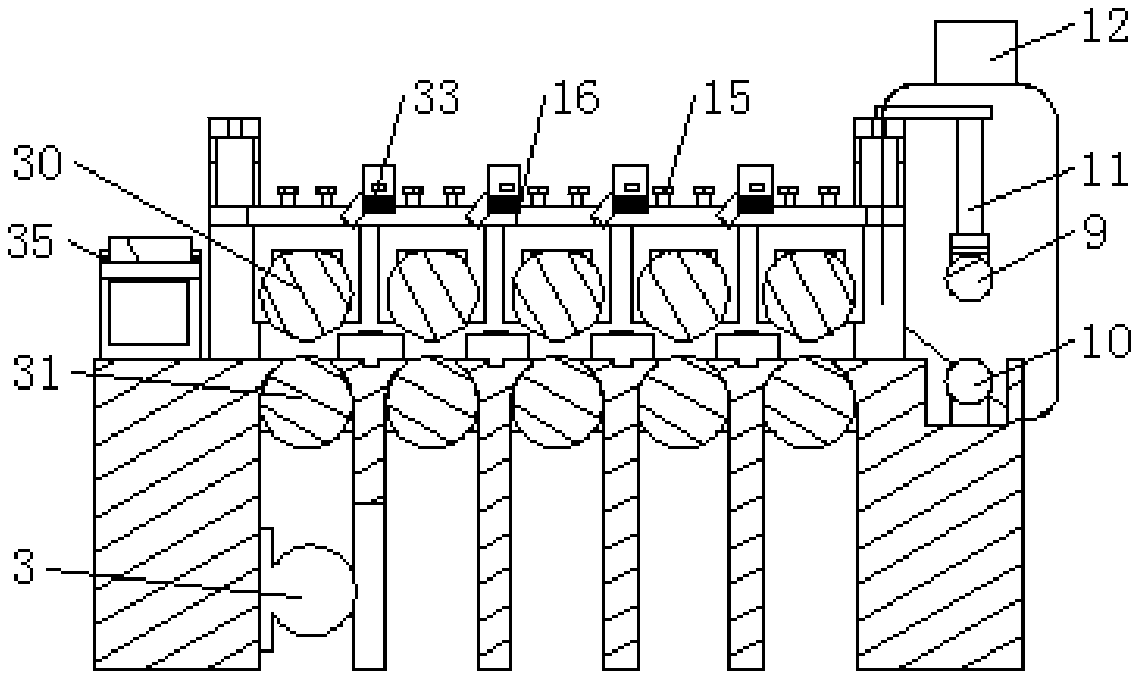

Technology for factorization high-quality and efficient cultivating of hypsizygus marmoreus

The invention relates to the field of edible fungus, and in particular relates to a technology for the factorization high-quality and efficient cultivating of hypsizygus marmoreus. The method is realized through the following technical scheme: a liquid seed is used firstly to be inoculated in a cultivation bottle fully filled with compost, solid fungus are directly inoculated, after the bottle is fully cultivated, fungus production and after-ripening cultivation is carried out for 25-35 days, mycelium stimulation is directly carried out for fruiting. By utilizing the technology, the whole fungus production cultivation period is shortened into 60-65 days from the 80-90 days of convention cultivation with one inoculation, and about 40% of cultivation period is shortened. In addition, about 30% of cultivation area, cultivation energy recourses and 40% of cultivation bottle caps can be saved.

Owner:SHANDONG ZHENGHAN BIO TECH CO LTD +1

Correction device for producing plastic sheet

InactiveCN108312483AUniform thicknessRealize automatic correctionGrinding machine componentsPlane surface grinding machinesSprocketPlastic film

The invention discloses a correction device for producing a plastic sheet. The correction device comprises a pedestal, wherein the pedestal has an oblong structure; further, the surface of the pedestal is provided with mounting grooves; lower correction wheels are arranged in the mounting grooves; mandrels are fixedly arranged at the axis positions of the lower correction wheels; two ends of eachthe mandrel of the correspondingeach lower correction wheel are cooperatively mounted with mounting bases in the interior of and the mounting bases in the pedestal are cooperatively mounted through bearing pairs respectively; further, the end parts of the mandrels of the lower correction wheels are fixedly provided with sprocket wheels; the sprocket wheels at the end parts of the mandrels of the corresponding lower correction wheel is are connected with a sprocket wheel at the end part of an output shaft of a motor I through a chain I. The correction device for producing the plastic sheet adopts multistage correction wheels to correct the plastic sheet, is used for guaranteeing the sheet to be uniform in thickness, meanwhile, adopts a fan to cool the sheet, is used for quickening the setting of the sheet and preventing the generation of deformation in a processing process, meanwhile, adopts a sanding wheel to sand the sheet, and is used for guaranteeing surface evenness.

Owner:王诗韵

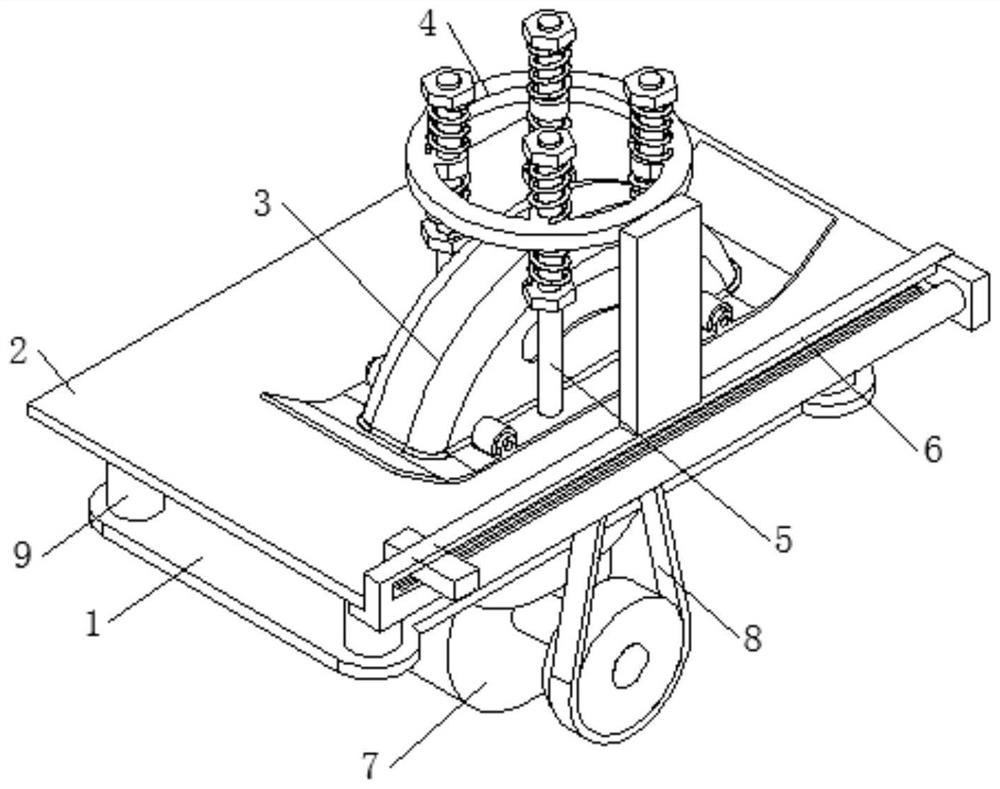

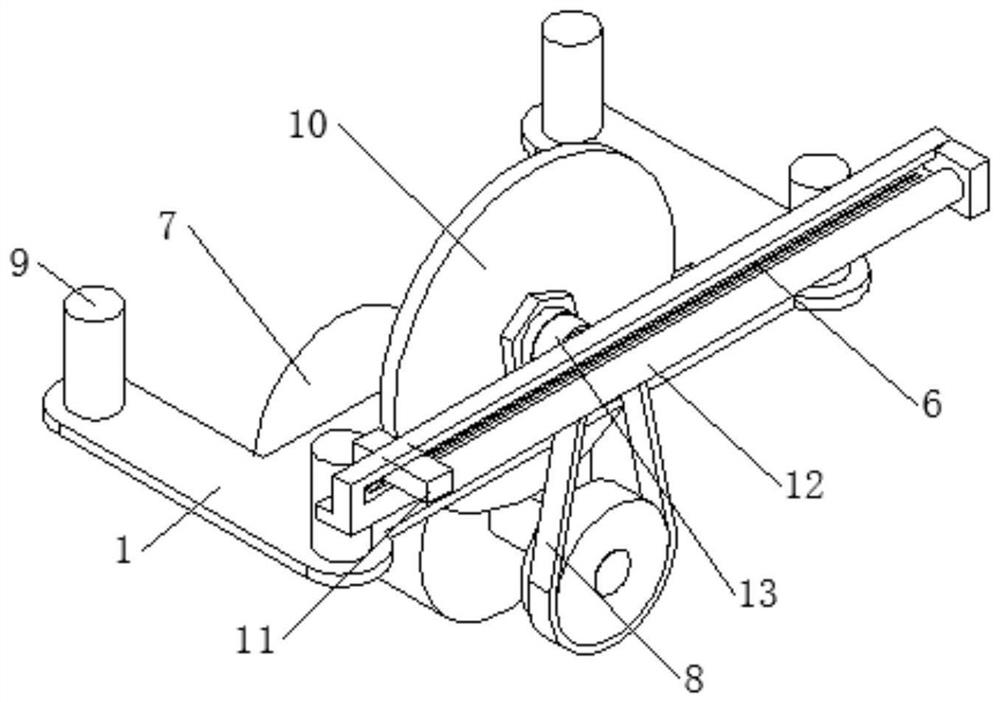

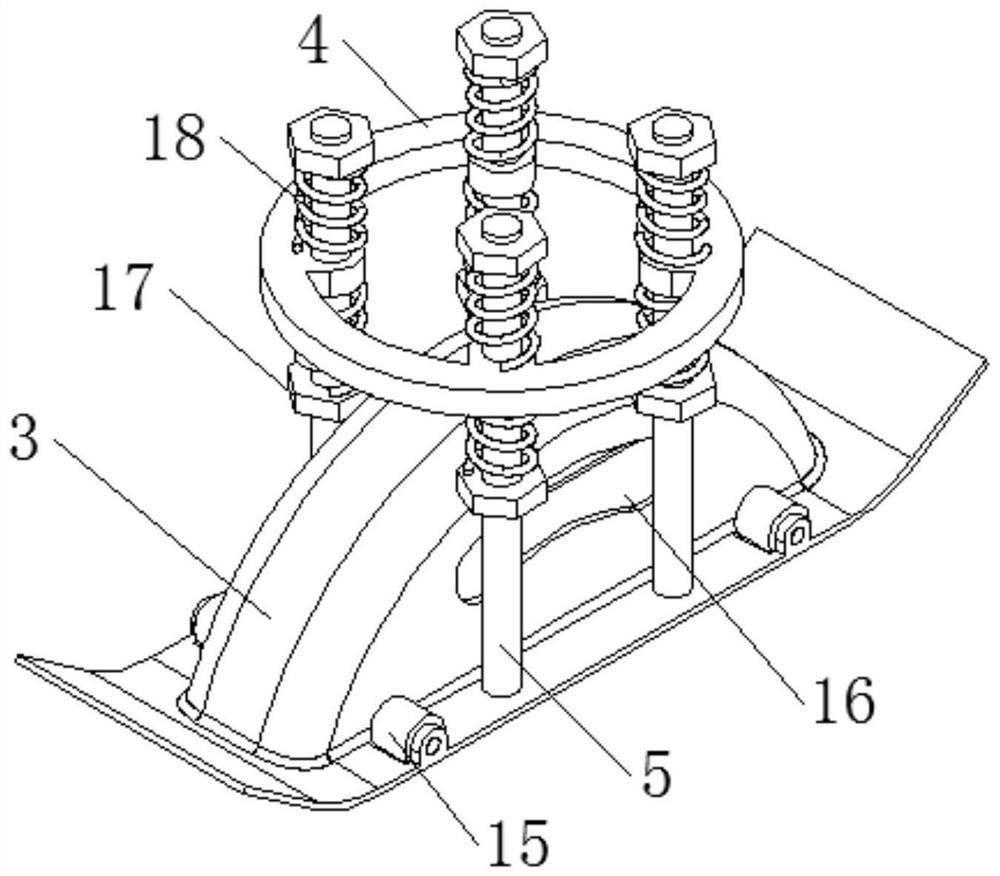

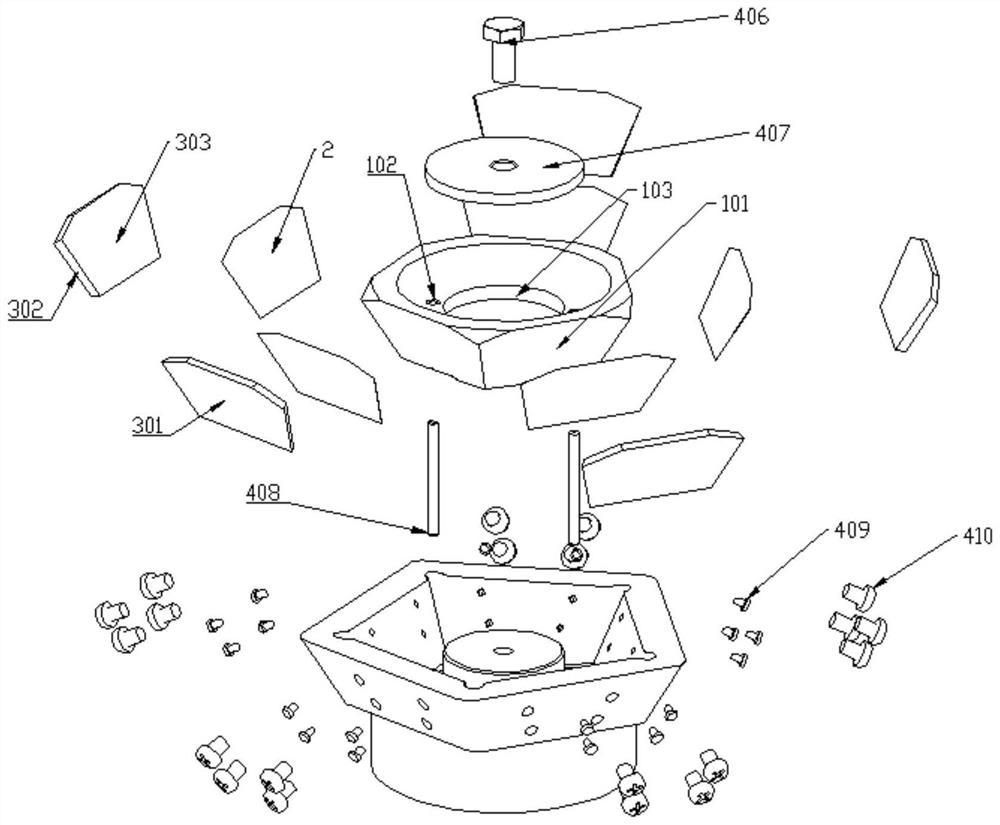

Anti-cutting table type electric saw

ActiveCN111660375AAvoid cutsSave the process of manual pressing and feedingCircular sawsElectric machineStructural engineering

The invention discloses an anti-cutting table type electric saw. The anti-cutting table type electric saw comprises a mounting frame and a workbench, a rectangular through hole is formed in the upperend of the mounting frame, rotating shaft mounting seats are arranged on the upper surface of the mounting frame and located on the two sides of the rectangular through hole, a main shaft is mounted in the rotating shaft mounting seats in a matched mode through bearing pairs, and a saw blade is mounted outside the main shaft in a matched mode; and a first belt wheel is mounted at the end of the main shaft in a matched mode, a motor is fixedly arranged at the lower end of the mounting frame through a motor mounting base, the motor is connected with an external power source through a control switch set, and a second belt wheel is mounted at the end of an output shaft of the motor in a matched mode. According to the anti-cutting table type electric saw, the mode that a feeding mechanism is arranged on the side edge of the workbench is adopted, automatic feeding of short and small workpieces is achieved, manual finger pressing for feeding is not needed, fingers are prevented from being cut, and a protective shell is additionally arranged above the saw blade, so that the saw blade is prevented from hurting people.

Owner:浙江具京科技发展有限公司

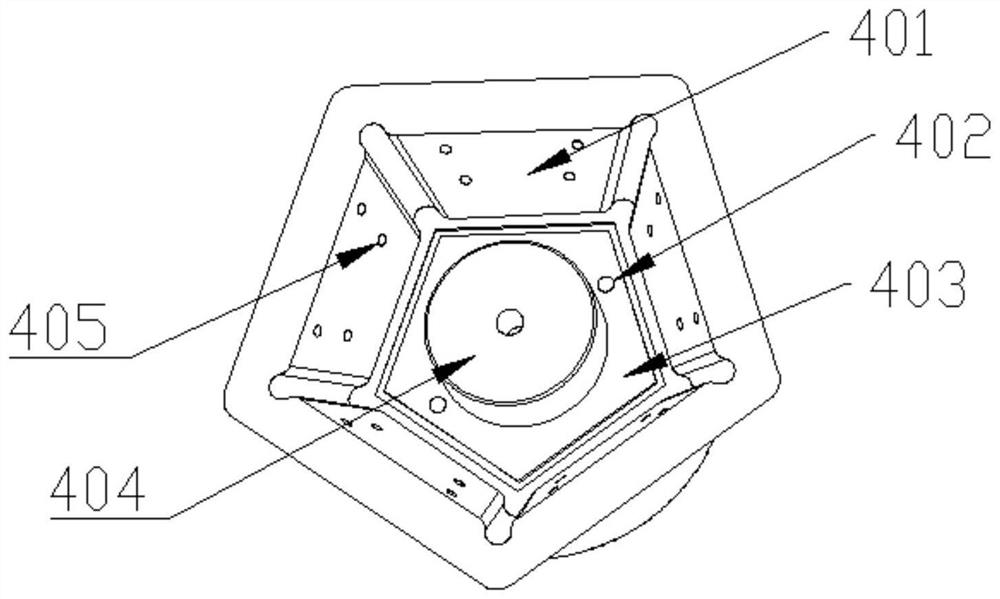

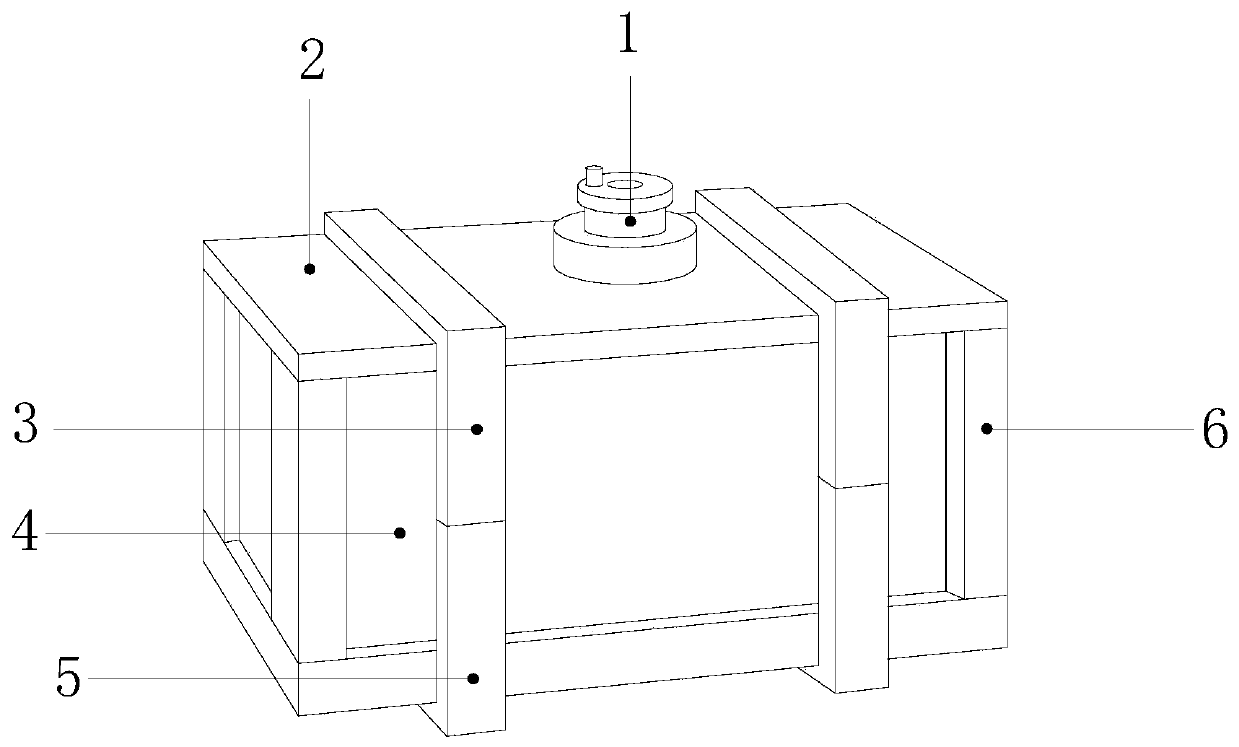

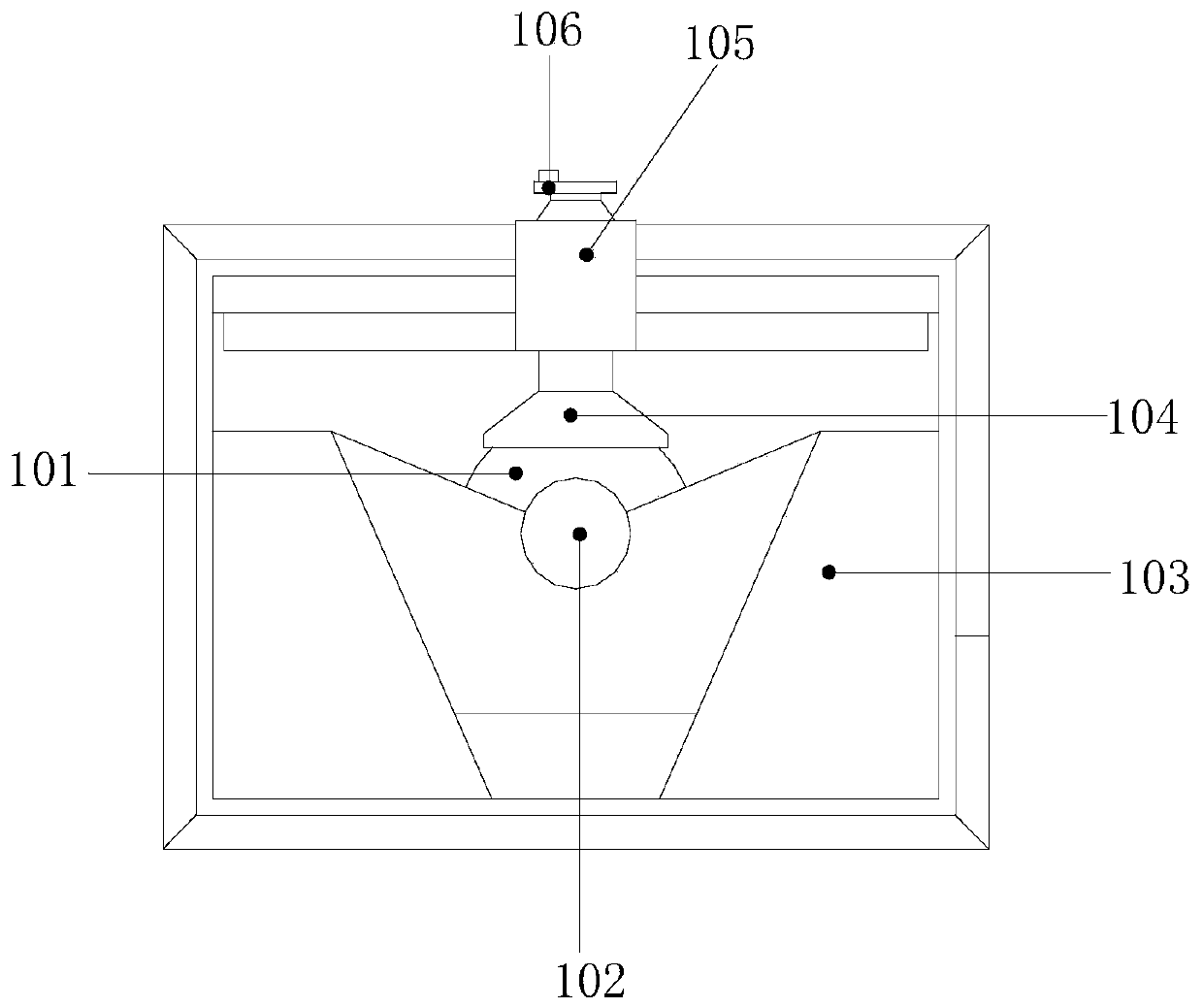

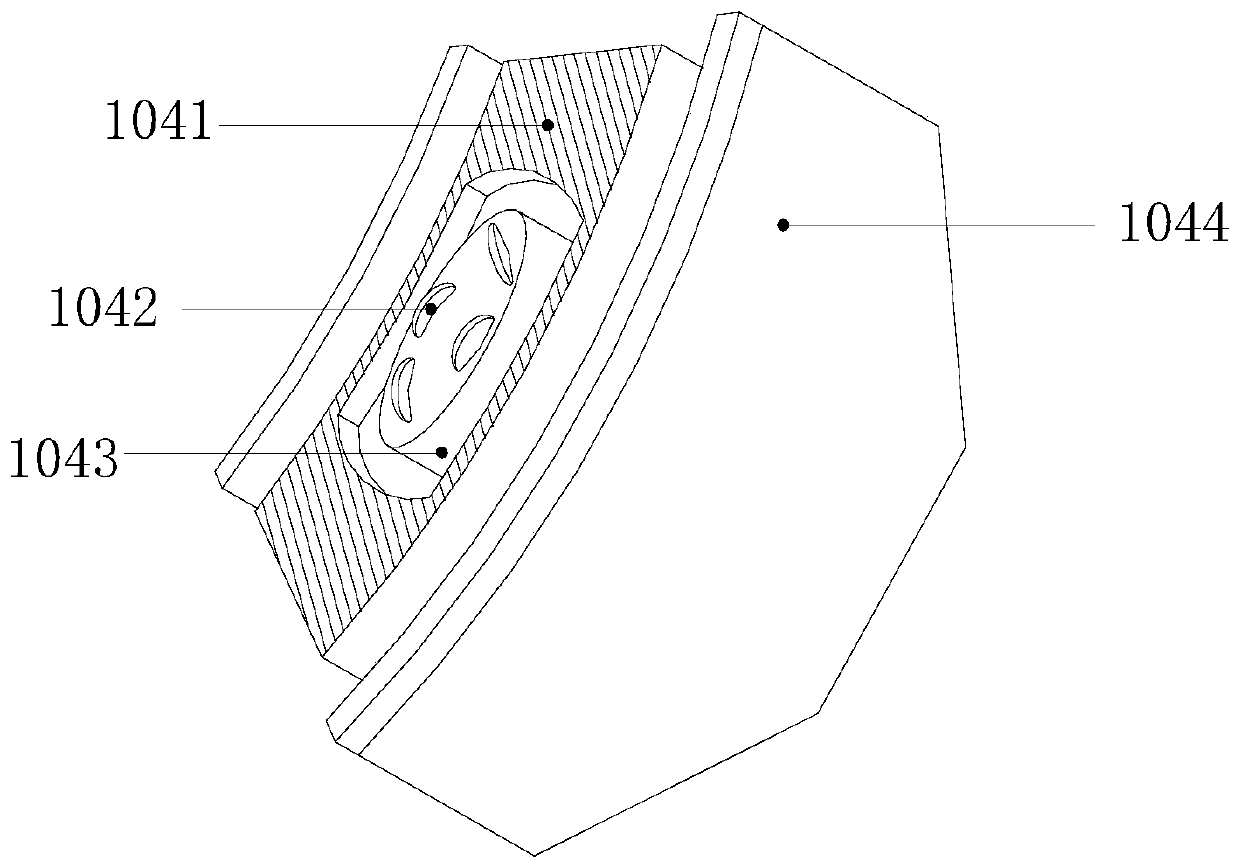

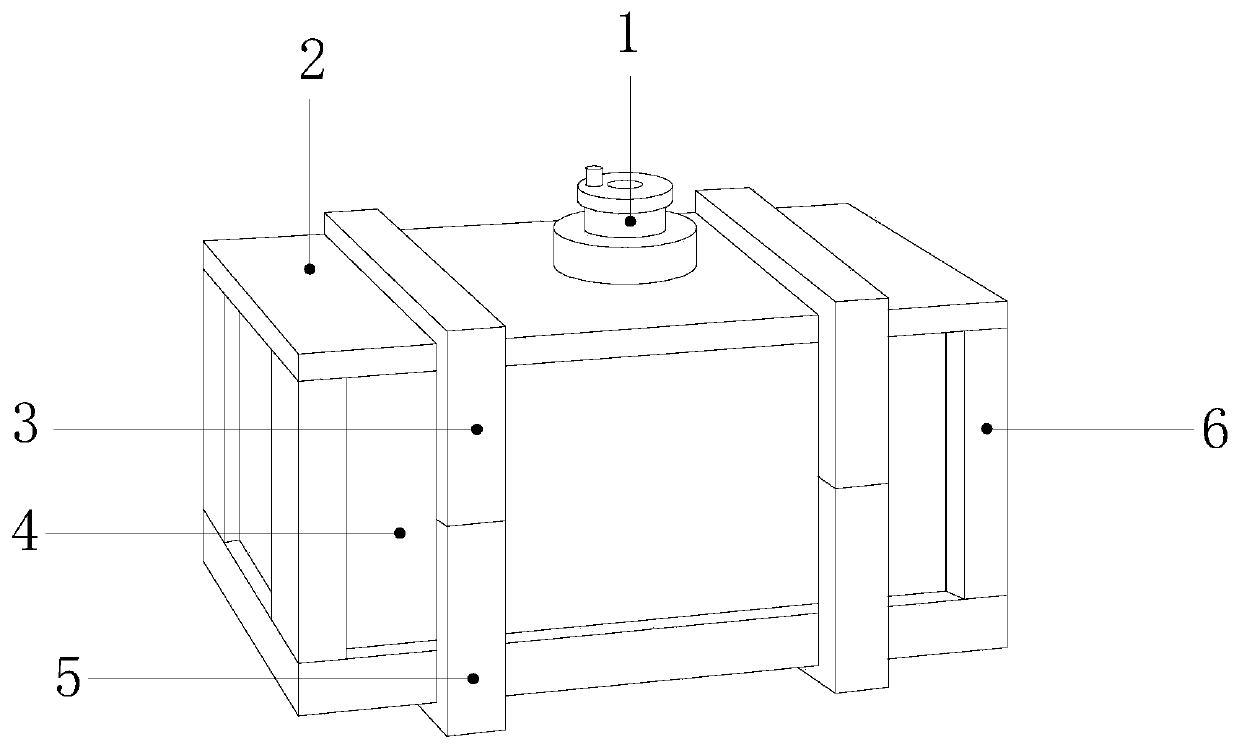

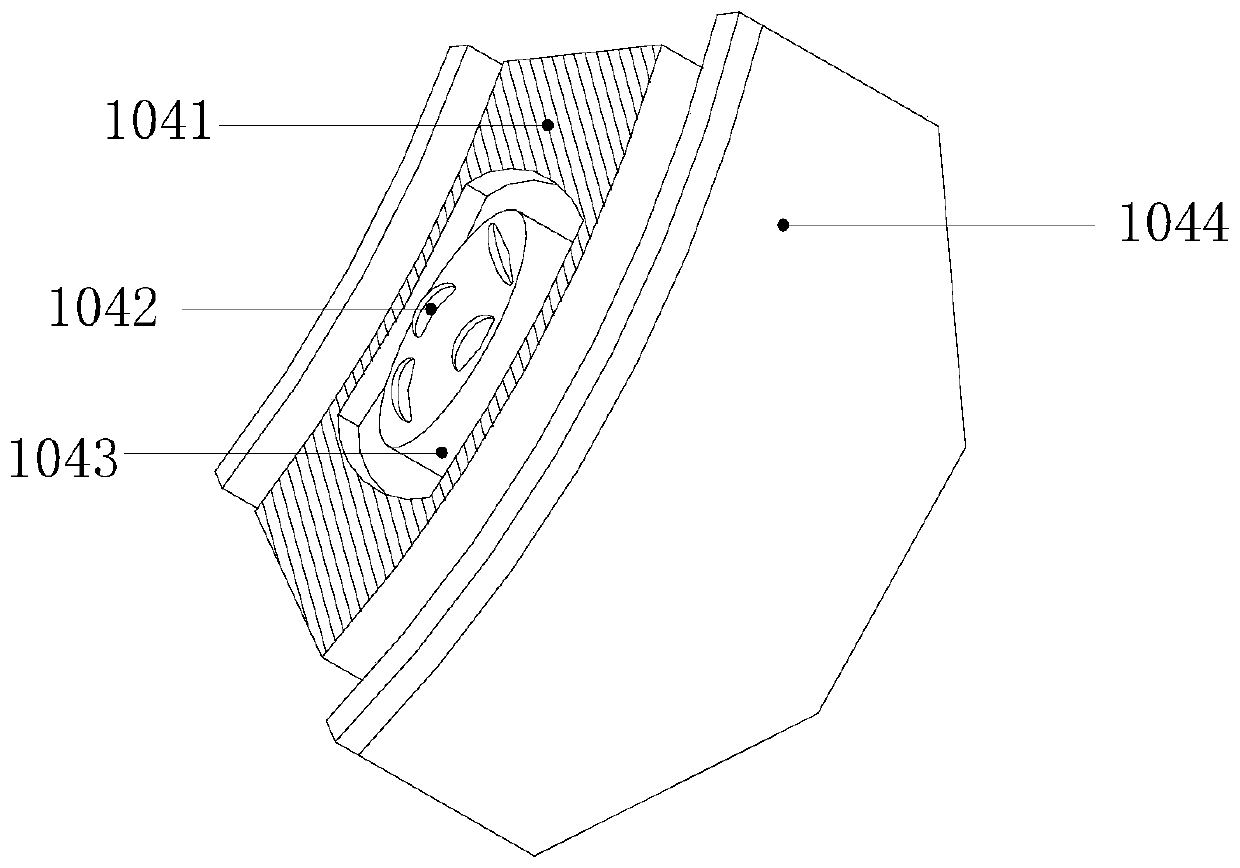

Surface mount type multi-surface rotating mirror scanning system and manufacturing method thereof

ActiveCN114460560AAchieve mass productionReduce the difficulty of productionWave based measurement systemsSurface mountingEngineering

The invention discloses a patch type multi-surface rotating mirror scanning system and a manufacturing method, the scanning system comprises a base, a plurality of positioning planes are arranged on the side surface of the base, and reflectors are arranged on the positioning planes, and the patch type multi-surface rotating mirror scanning system is characterized in that the reflectors are welded and fixed on the positioning planes; the surface mount type multi-surface rotating mirror scanning system has the advantages that aiming at the problems of poor surface type, low angle precision and low reliability at high temperature and high rotating speed in the use process of the surface mount type multi-surface rotating mirror scanning system, the plurality of reflectors are simultaneously welded and fixed on the base in a welding manner, so that the production difficulty is reduced, the angle precision and good surface type can be ensured, and the production efficiency is improved. The reliability of the system is improved, the system can stably work in the high-temperature and high-rotating-speed environment, and large-scale production can be achieved.

Owner:NINGBO YONGXIN OPTICS

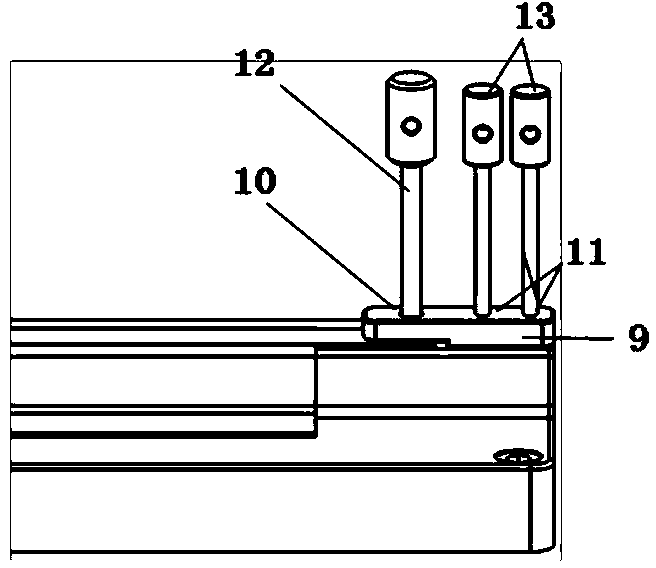

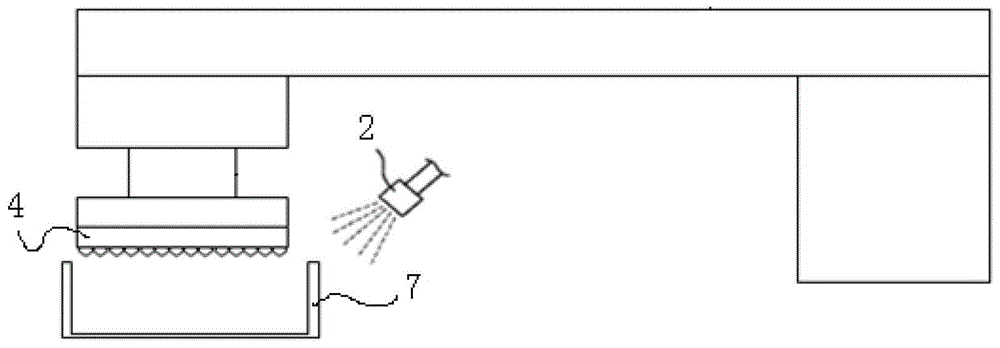

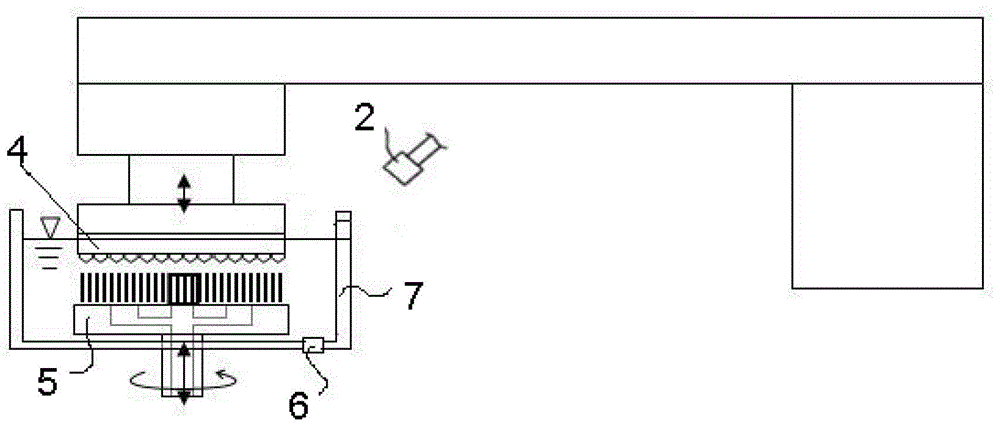

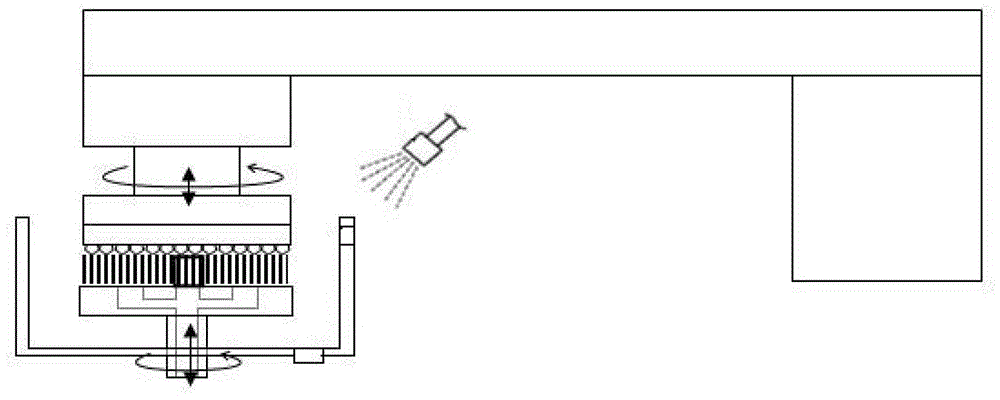

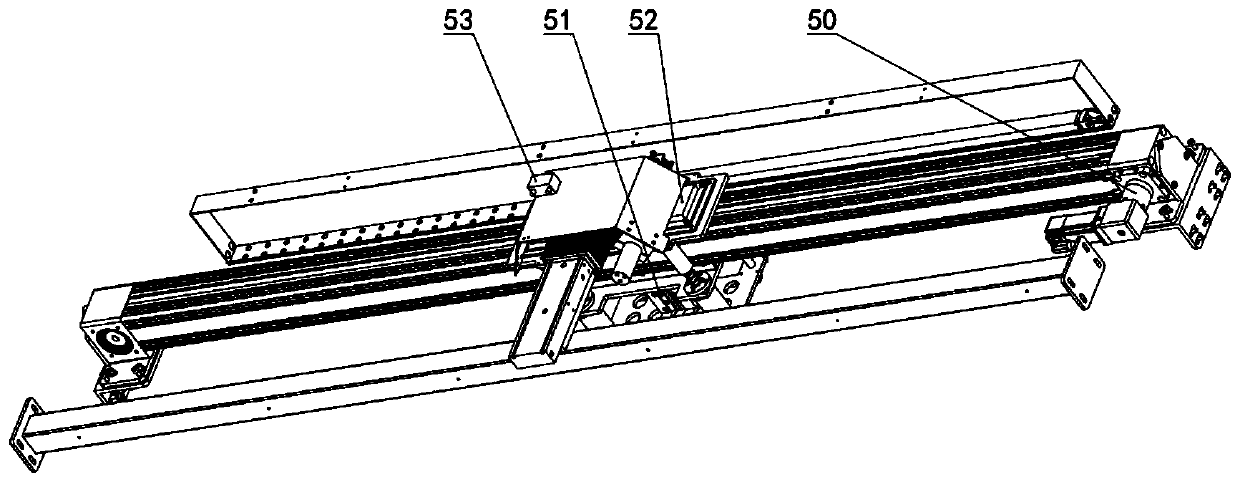

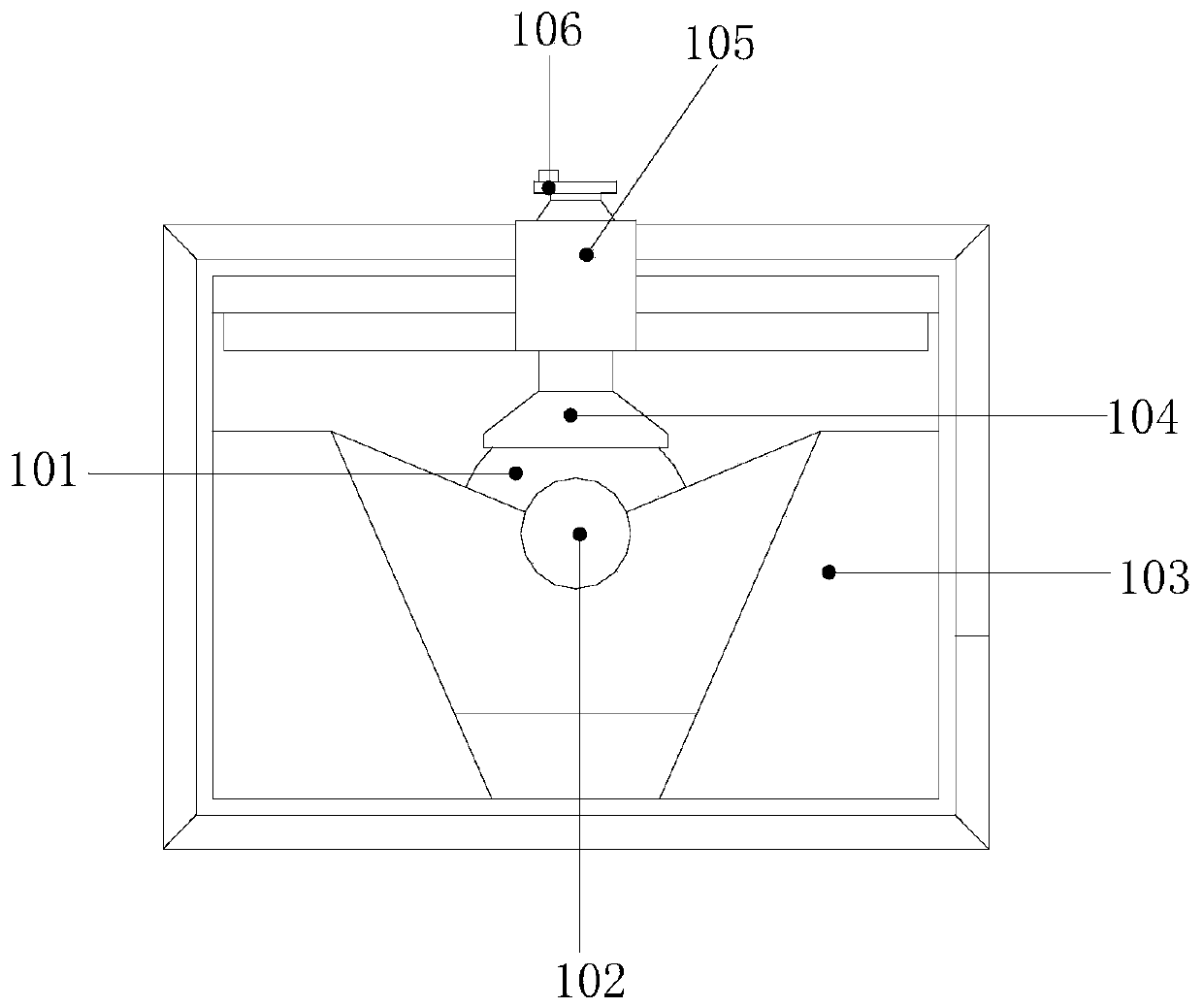

Cleaning device of powder laying equipment of powder 3D (three-dimensional) printer

PendingCN110142961AHigh scrubbing efficiencyGuaranteed surfaceAdditive manufacturing apparatus3D object support structures3D printingServo drive

The invention provides a cleaning device of powder laying equipment of a powder 3D (three-dimensional) printer, and relates to the technical field of 3D printing. The cleaning device is designed for solving the problem that the powder laying equipment of the existing 3D printer cannot be cleaned up. The powder laying equipment of the 3D printer comprises a servo driving module, an air cylinder lifting adjustment module, a wiping module and a cleaning atomization module, wherein the cleaning atomization module is a device for cleaning the wiping module and spraying mist to wet the wiping module; the servo driving module is used for driving the air cylinder lifting adjustment module and the wiping module to reciprocate together; the lifting adjustment module is used for driving the wiping module to move up and down; and thus, the automatic cleaning of the powder laying equipment is realized, and the problem that the powder laying equipment cannot be cleaned up is solved.

Owner:NINGXIA KOCEL MOLD

Prepn of super-paramagnetic polymer microsphere

InactiveCN1219817CSolving Dispersion ProblemsFix compatibility issuesInorganic pigment treatmentPolymer sciencePolyolefin

The present invention provides the preparation process of super-paramagnetic polymer microsphere. The super-paramagnetic polymer microsphere consists of polyolefin polymerized with lipophilic olefin monomer and organic monomer with hydrophilic functional radical and coated nano magnetic grains of modified ferroferric oxide. The nano magnetic grains with one surface lipophilic layer can be well dispersed in organic matter to form magnetic fluid and dispersed inside polymer microsphere to obtain super-paramagnetism. The microsphere is regular and has size of 0.1-5 micron and has magnetic ferroferric oxide accounting for 0.5-40 wt% of the whole micro microsphere. The present invention has the advantages of simple preparation process, narrow microsphere size, regular appearance, high functional radical content, homogeneous magnetism, stable chemical performance and acid and alkali resistance.

Owner:北京倍爱康生物技术有限公司 +1

A method for manufacturing a large-scale high-strength superhard hollow round ingot

The invention relates to a hollow billet and a manufacturing method thereof, and especially relates to a large-size and high-strength super hard hollow billet and a manufacturing method thereof. The purpose of the invention is to solve the problems of low yield, large production workload and difficult process control of casting of aluminum alloy hollow ingots prepared in the prior art. The large-size and high-strength super hard hollow billet comprises Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, B and Al. The manufacturing method comprises the following steps: 1, weighing; 2, smelting; 3, refining and casting of melt; and 4, molding. The method is mainly used for manufacturing the large-size and high-strength super hard hollow billet.

Owner:NORTHEAST LIGHT ALLOY CO LTD +1

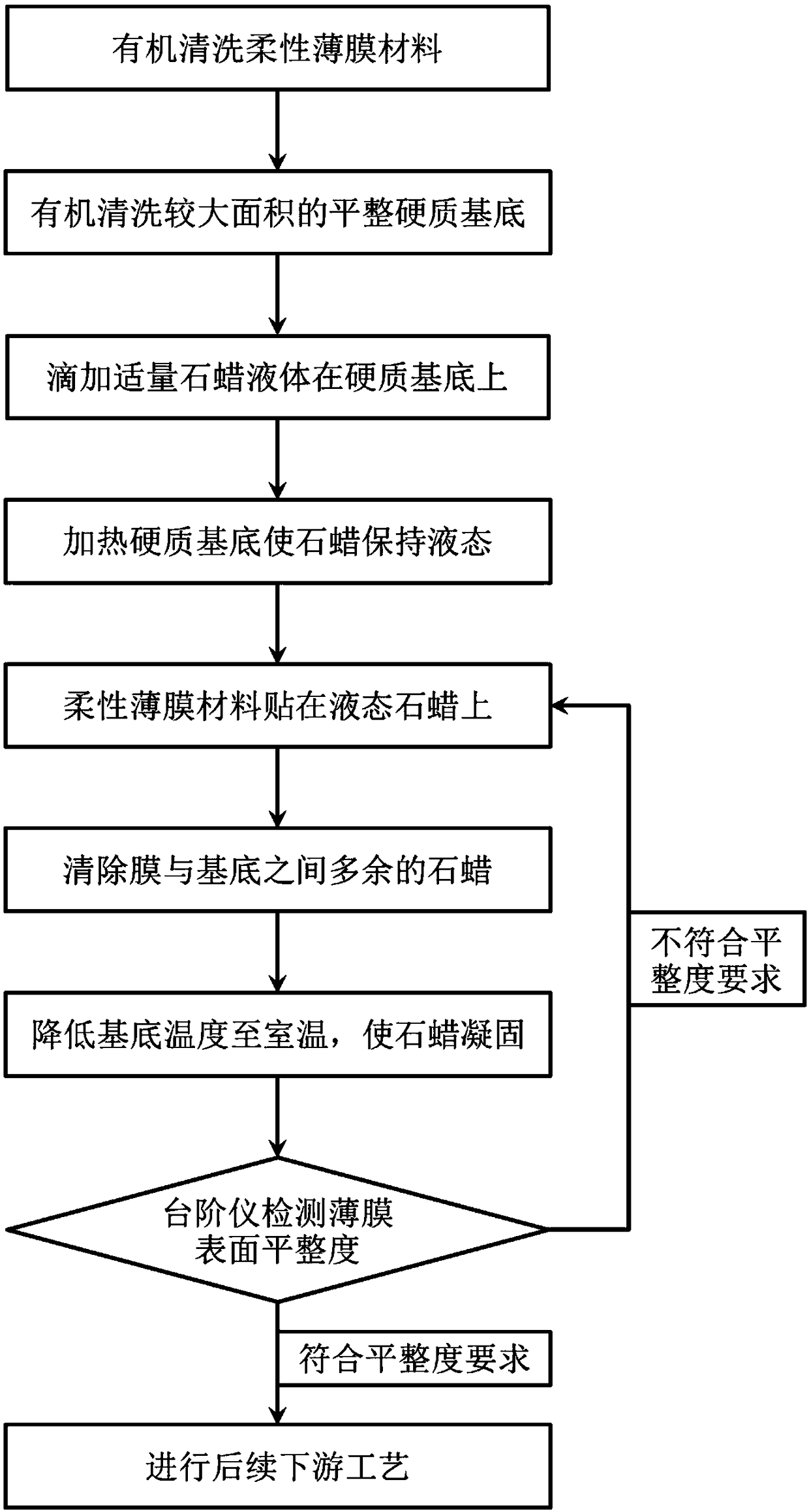

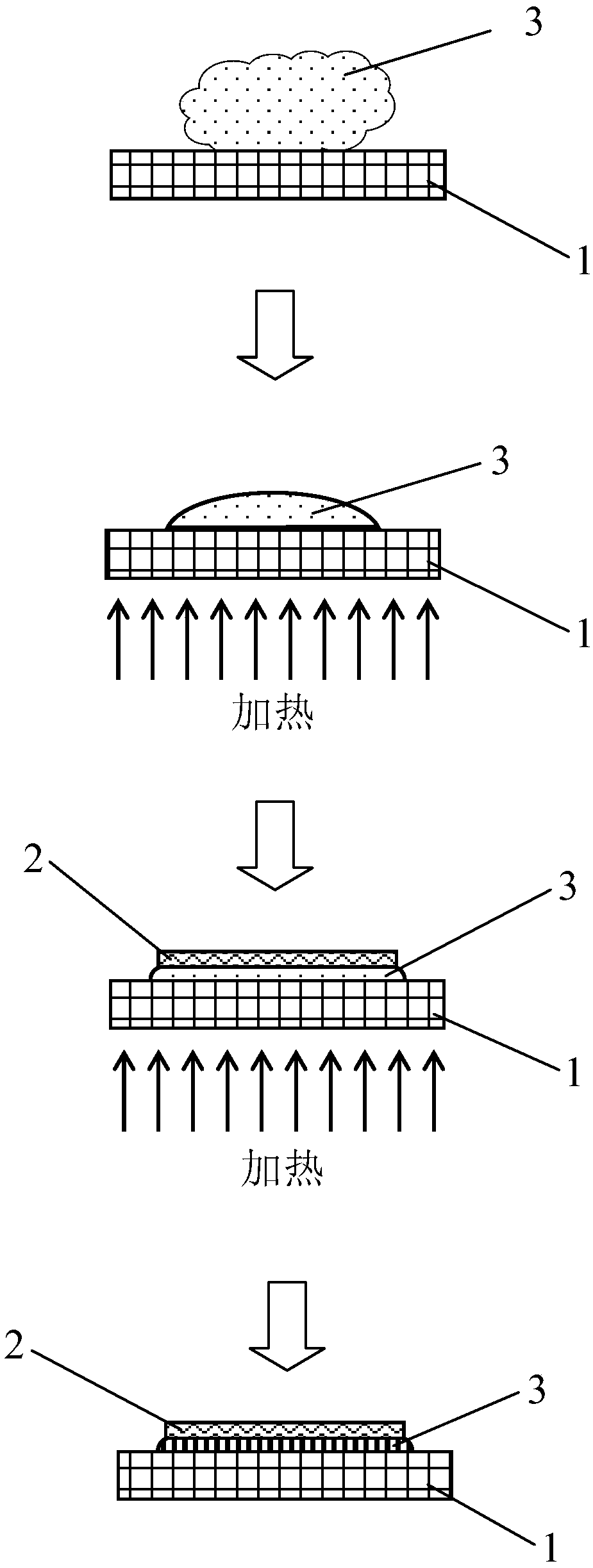

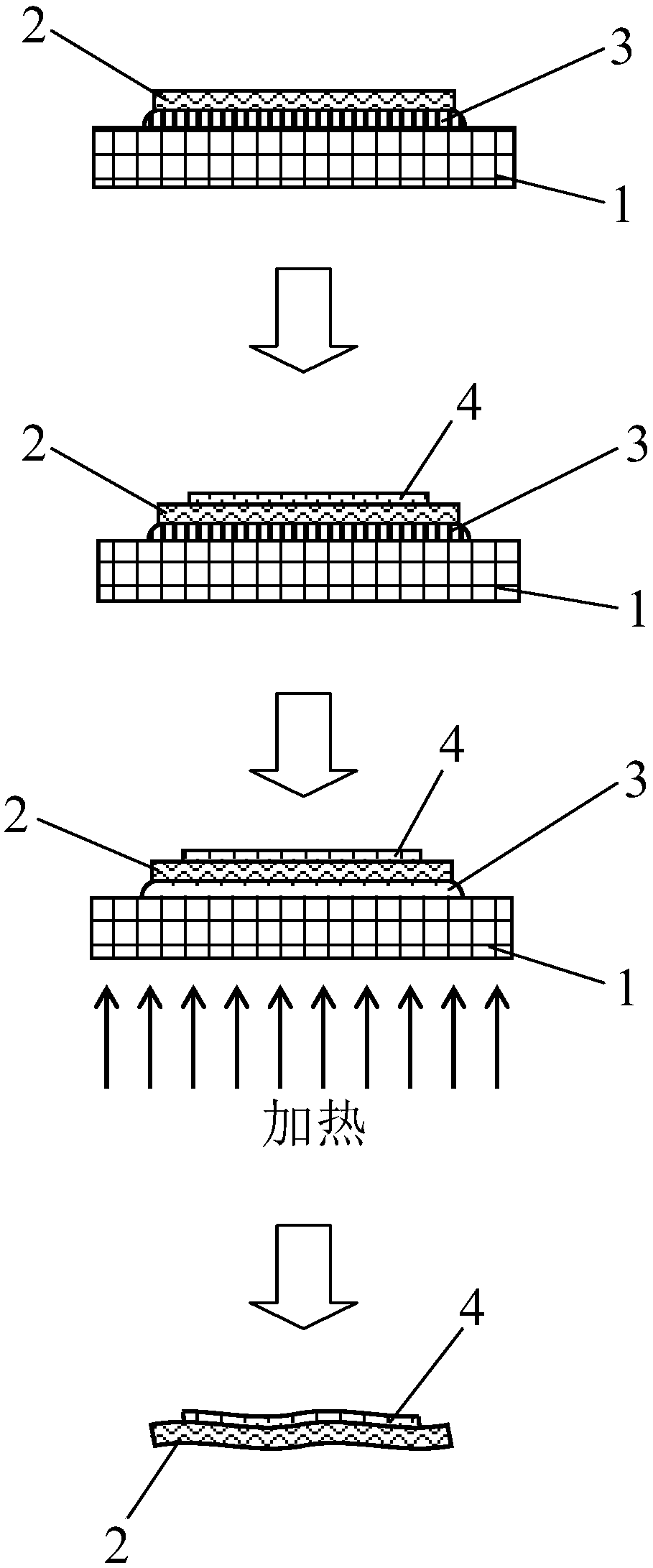

Leveling method of flexible thin film material and application of leveling method

InactiveCN108400239AImprove adhesionSolve the flatnessFinal product manufactureSolid-state devicesWaxLiquid state

The invention relates to a leveling method of a flexible thin film material. The leveling method comprises the following steps of S1, cleaning a hard substrate and the flexible thin film material; S2,placing liquid-state wax on the hard substrate; S3, allowing one side of the flexible thin film material to be in contact with the liquid-state wax on the hard substrate, and leveling the flexible thin film material from one side in contact with the liquid-state wax to the other side; S4, extruding the flexible thin film material by a leveling surface to remove residual liquid-state wax; and S5,performing temperature reduction and cooling to make the liquid-state wax between the flexible thin film material and the hard substrate solidified, and smoothly fixing the flexible thin film materialon the hard substrate. The invention also relates to application of the leveling method in fabrication of a flexible electronic device. By the leveling method of the flexible thin film material, thesmoothness of a surface of the flexible thin film material can be effectively ensured, and the leveling method has the advantage of low cost, is simple to operate and can be applicable to an inorganic / organic micronano processing technology.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A wooden packaging box for oil drill pipe joints based on the principle of side milling

ActiveCN109969552BGuaranteed surfaceMake sure the surface is cleanCleaning using toolsInternal fittingsStructural engineeringResidual oil

The invention discloses a wooden packaging box for petroleum drill pipe joints based on the principle of side-rolled smooth surfaces. Its structure includes a side-roller, a sealing cover, a fixed clamp, a loading box, a bottom frame, and fastening strips. There are more than two, and they are installed on the four corners of the side of the loading box through buckling. The two ends of the bottom of the loading box are connected to the bottom frame through buckling, and the upper ends of the bottom frame are buckled with the slots of the fixed clips. When the drill pipe joint needs to be taken out, the invention can introduce the petroleum diluent through the filling mechanism to diffuse it in the purification cotton brush. At this time, the inner spindle rotates the grinding wheel, thereby turning the drill pipe joint over, and cooperates with the purification Use a cotton brush to remove oil stains to ensure that the surface of the drill pipe joint is clean when it is taken out, and to prevent residual oil stains from causing hand slippage and affecting the movement.

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

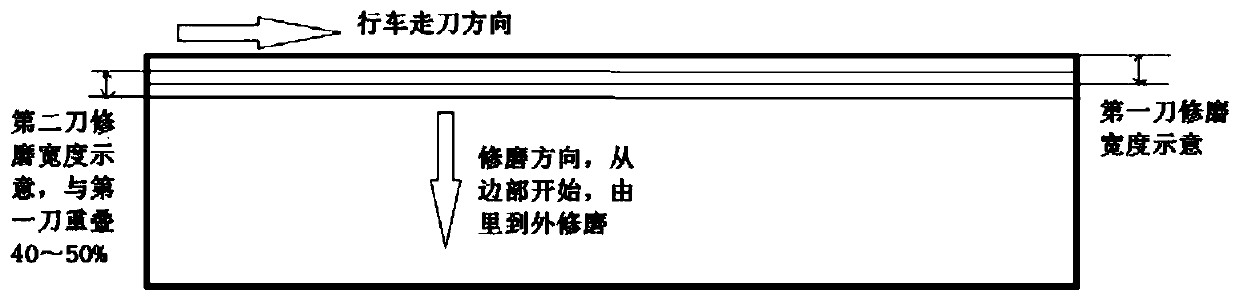

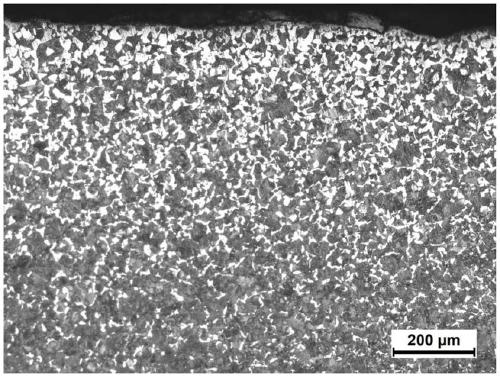

Rolled square billet peeling method

PendingCN111136555AGuaranteed surface qualityGuaranteed surfaceEdge grinding machinesGrinding feed controlEngineeringBluing

The invention relates to the field of steel, in particular to a rolled square billet peeling method. The method comprises the following steps that the peeling depth of the plane part is 0.30-0.95 mm,the peeling depth of the corner angle part is less than 1.05 mm, in a peeling process, and the ratio K of the rotating speed of a grinding wheel to the speed of a trolley is 70 to 125. The surface ofthe peeled billet obtained through the peeling method of the rolled square billet is free of peeling defects such as grinding residues, residual black rust, flashes and burrs, corner transition is smooth, surface defects of a decarburized layer and cogging rolling are completely removed, the surface is free of bluing, the ratio K of the rotating speed VZ of the grinding wheel to the longitudinal travelling speed VL of the trolley ranges from 70 to 125, peeling can be carried out accurately, the ratio K of the rotating speed VZ of the grinding wheel to the travelling speed VL of the trolley iscontrolled to range from 70 to 125, the peeling efficiency can be improved, the risk of billet surface burn can be well reduced, and peeled billet surface quality is improved.

Owner:SGIS SONGSHAN CO LTD

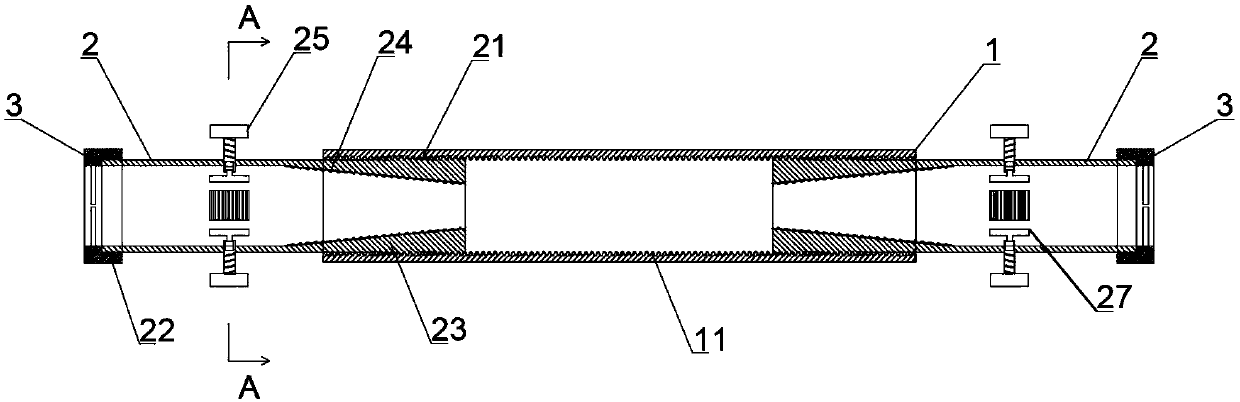

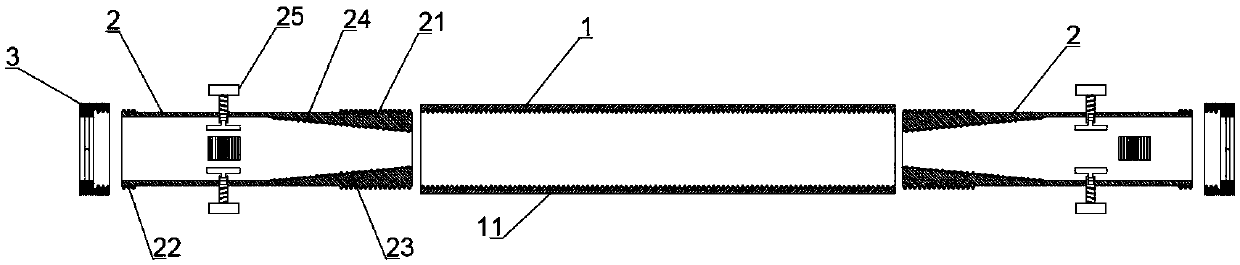

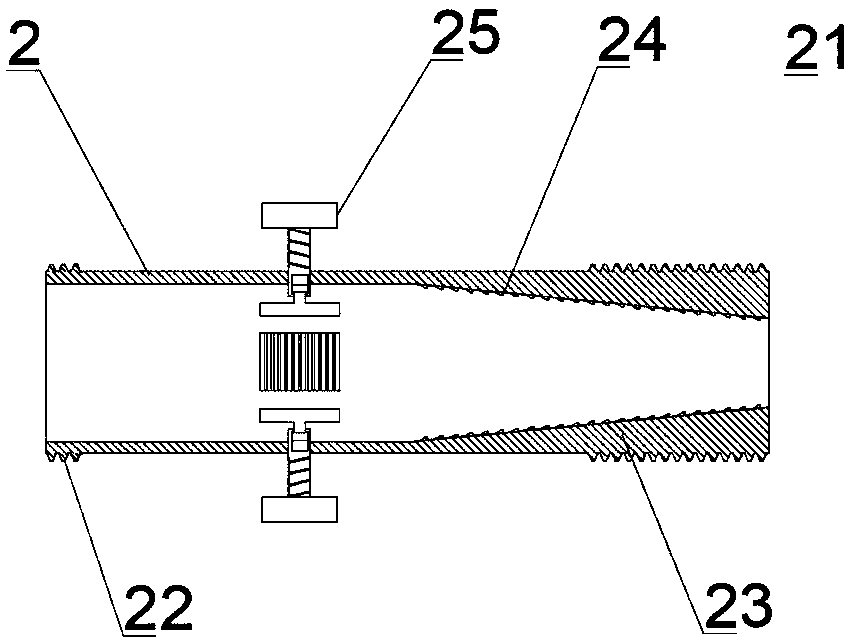

Linear cutting tensioning balance variable mechanism

PendingCN109822169AReduce tensionExtended service lifeElectrical-based machining electrodesEngineeringMechanical engineering

The invention discloses a linear cutting tensioning balance variable mechanism. The linear cutting tensioning balance variable mechanism comprises an upper supporting wheel, an upper guide wheel, an upper heavy punch, a lower supporting wheel, a lower guide wheel, a lower heavy punch, a diameter measuring mechanism and a controller, wherein the upper supporting wheel and the lower supporting wheelcan be both transversely arranged on a machine body of a linear cutting machine in a sliding mode; the upper heavy punch and the lower heavy punch both comprise shells and at least two weights, wherein the shells are connected with the machine body of the linear cutting machine body, the weights are arranged in the shells from top to bottom, and the weights are connected with the weights throughelectromagnets; a steel wire penetrates through the shells and is connected with the weights on the top, the upper guide wheel and the lower guide wheel are both connected with the machine body of thelinear cutting machine; the weights of the upper heavy punch and the weights of the lower heavy punch are all connected with the upper supporting wheel and the lower supporting wheel through steel wires correspondingly, are hung on the upper guide wheel and the lower guide wheel correspondingly, and are used for providing tensioning force; a wire diameter measuring mechanism is used for measuringthe diameter of a molybdenum wire, and the controller is used for controlling the electromagnets according to the measuring result of the wire diameter measuring mechanism. The mechanism has the advantages that the service life of the molybdenum wire is prolonged, and the cutting precision is improved.

Owner:福建合盈机械有限公司

Composite board furniture oil paint process

InactiveCN106076777AEasy to makeShort curing timeLiquid surface applicatorsCoatingsSurface finishingVarnish

The invention discloses a composite board furniture oil paint process. The composite board furniture oil paint process includes the following steps of (1) drying; (2) process treatment; (3) uniform varnish spraying; (4) surface cleaning; (5) primer spraying; and (6) surface treatment. According to the composite board furniture oil paint process, manufacturing is convenient, the curing time is short, cost is low, oil paint can be stored for a long time and can be produced on a large scale, is more resistant to abrasion and higher in anti-scratching capacity than common oil paint, is long in service life, and more effectively guarantee the surface of our furniture, and it can be guaranteed that a wall face is protected against damage by adding iron powder.

Owner:柳州市优联科技开发有限公司

A window lift system

ActiveCN104612547BImprove comfortGuaranteed surfaceWindowsWindscreensStructural engineeringMechanical engineering

The invention discloses a vehicle window glass lifting system. The vehicle window glass lifting system comprises: a vehicle window glass, a glass lifter and two parallel guide rails. In the present invention, the vehicle window glass is arranged between two parallel guide rails, the vehicle window glass is designed as a curved surface structure, and the track line of the guide rail is a curve, and the track line of the guide rail and the vehicle window glass are located on the same curved surface. The window glass with curved surface structure is beautiful in shape, which meets the needs of modern people for the appearance and comfort of the car. It moves smoothly in the two parallel guide rails, avoiding the difficulties in lifting and lowering the window glass, jamming, wear of the guide rails, and rattling of the windows caused by track deviation between the window glass and the guide rails, and improving the safety of the windows. comfort.

Owner:CHERY AUTOMOBILE CO LTD

Polymer material furniture paint preparation process

InactiveCN106111501AGuaranteed surfaceFree from destructionPretreated surfacesCoatingsPolymer scienceIron powder

The invention discloses a polymer material furniture paint process, which comprises the following steps: (1) drying; (2) process treatment; (3) evenly spraying varnish; (4) surface cleaning; (5) spraying primer; (6) ) surface treatment. The invention is easy to manufacture, fast in curing time, low in cost, can be preserved for a long time, and can be produced on a large scale. It is more wear-resistant and scratch-resistant than ordinary paints, and has a long service life. , The addition of iron powder can protect the wall from damage.

Owner:柳州市优联科技开发有限公司

An ultrasonic lead-acid battery

ActiveCN110931891BImprove reliabilityDecay of power storage performanceFinal product manufactureElectrolyte/reactants regenerationElectrolytic agentEngineering

The invention relates to an ultrasonic lead-acid storage battery, which includes a battery case, a battery cover, a cluster group, and at least one ultrasonic transducer. A receiving chamber is opened on the top of the battery case, and a liquid discharge port penetrating into the receiving chamber is provided on the outer wall of the battery case. , there is a sealing plug in the drain port, and a number of insulating and corrosion-resistant vibrating strips are installed at the bottom of the battery cover. The cluster group includes a number of positive plates, a number of negative plates, and a number of separators. The separators are respectively arranged between the positive electrode plate and the negative electrode plate, the clusters are arranged in the accommodation cavity, and the vibrating strips are respectively inserted between the positive electrode plate and the separator, and between the negative electrode plate and the separator, and the ultrasonic transducer is set on top of the battery cover. By using high-frequency ultrasonic vibration to prevent lead sulfate crystals on the surface of the battery plate, to maintain full and comprehensive contact between the battery plate and the electrolyte, it can greatly alleviate the attenuation of the storage performance of the battery and prolong the service life of the battery.

Owner:彭志军

Petroleum drill pipe joint wooden packaging box based on smooth surface side rolling principle

ActiveCN109969552AGuaranteed surfaceMake sure the surface is cleanCleaning using toolsInternal fittingsResidual oilPetroleum

The invention discloses a petroleum drill pipe joint wooden packaging box based on the smooth surface side rolling principle. The petroleum drill pipe joint wooden packaging box structurally comprisesa side rolling device, a sealing cover plate, fixing clamps, a loading box body, bottom frames and two or more fastening bars. The two or more fastening bars are mounted at the four corners of the side face of the loading box body in a buckled mode. The two ends of the bottom of the loading box body are connected with the bottom frames in a buckled mode. The upper ends of the bottom frames are buckled to grooves of the fixing clamps. When a drill pipe joint needs to be taken out, the petroleum drill pipe joint wooden packaging box can guide a petroleum thinner in through a filling mechanism to enable the petroleum thinner to be diffused in a purifying cotton brush. At the moment, an inner spindle rotates to drive a rolling wheel, the drill pipe joint is turned over, and the purifying cotton brush is used in cooperation to brush away oil stain. Accordingly, it is ensured that the surface of the drill pipe joint is clean when the drill pipe joint is taken out to prevent the situation that residual oil stain causes hand slipping and has the effect on carrying.

Owner:NANTONG TAIYING NEW MATERIAL SCI & TECH CO LTD

Technology for factorization high-quality and efficient cultivating of hypsizygus marmoreus

The invention relates to the field of edible fungus, and in particular relates to a technology for the factorization high-quality and efficient cultivating of hypsizygus marmoreus. The method is realized through the following technical scheme: a liquid seed is used firstly to be inoculated in a cultivation bottle fully filled with compost, solid fungus are directly inoculated, after the bottle is fully cultivated, fungus production and after-ripening cultivation is carried out for 25-35 days, mycelium stimulation is directly carried out for fruiting. By utilizing the technology, the whole fungus production cultivation period is shortened into 60-65 days from the 80-90 days of convention cultivation with one inoculation, and about 40% of cultivation period is shortened. In addition, about 30% of cultivation area, cultivation energy recourses and 40% of cultivation bottle caps can be saved.

Owner:SHANDONG ZHENGHAN BIO TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com