Power wiring pipe

A wiring duct and power technology, applied in cable joints and other directions, can solve problems such as threats to the personal safety of maintenance personnel, damage to rubber insulation, and impact on service life, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

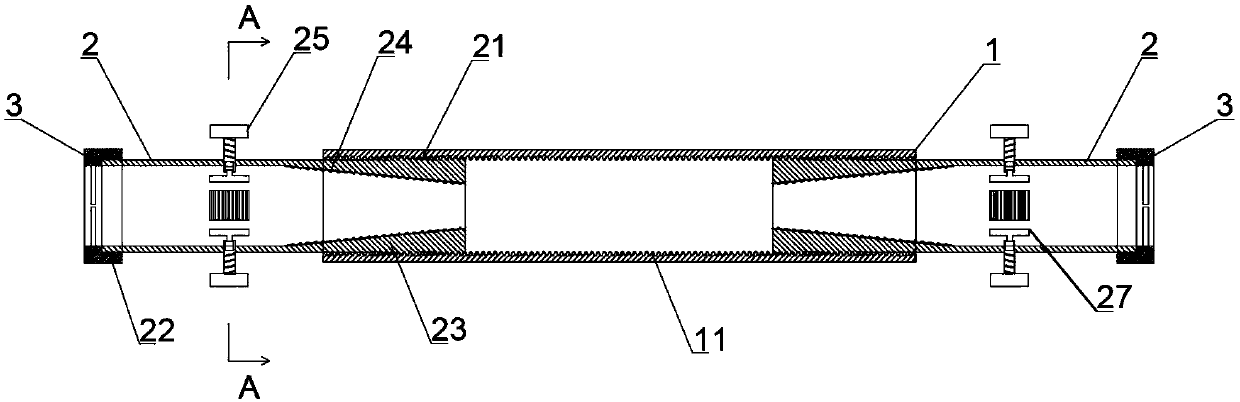

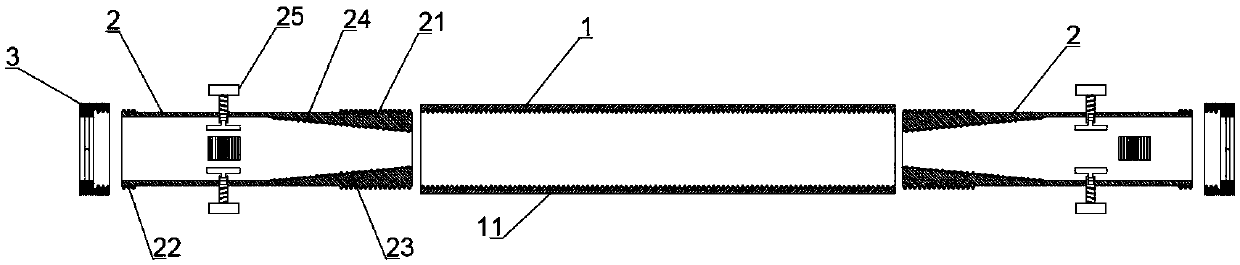

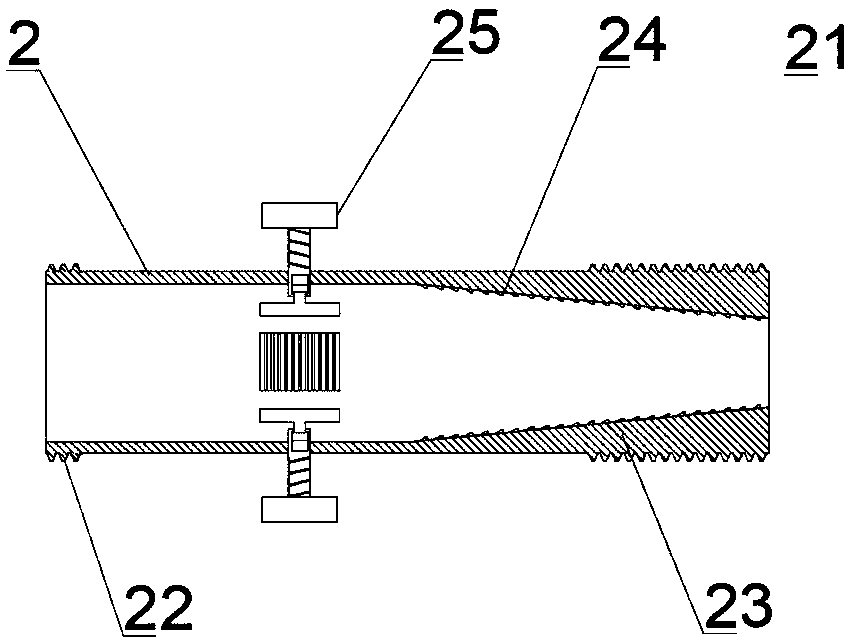

[0020] like Figures 1 to 6 As shown, this embodiment provides a power junction tube, which is made of thermoplastic elastomer as a whole, including a connecting tube 1, two fixing tubes 2 and a circular cover plate 3; the connecting tube 1 is a hollow cylindrical structure, and its The inner wall is provided with an internal thread 11; the fixed pipe 2 is a cylindrical structure matched with the connecting pipe 1, one end of the fixed pipe 2 is provided with a first external thread 21 matching the internal thread 11, and the other end is provided with a round cap The second external thread 22 matched with the plate 3; the fixed pipe 2 includes a tapered section and a fixed section, the tapered section and the fixed section have the same outer diameter; the inner diameter of the tapered section gradually decreases from inside to outside , forming a tapered structure 23 on the inner wall; the wall of the tapered structure 23 is provided with a barbed one-way tab 24; the fixed s...

Embodiment 2

[0022] like Figures 1 to 6 As shown, this embodiment provides a kind of power connection pipe, and the difference from Embodiment 1 is that the fixers are arranged in the shape of a "ten" and installed on the fixing section; the bottom of the fixing plate 27 is provided with a Anti-slip rubber anti-slip gasket; the middle section of the connecting pipe 1 is provided with an observation window made of polycarbonate material; the thermoplastic elastomer includes the following components: 50-60 parts by weight of ethylene acrylate elastomer rubber , 40-50 parts by weight of sarin resin, 5-10 parts by weight of epoxy resin, 4-6 parts by weight of zinc stearate, 10-30 parts by weight of filler, 3-5 parts by weight of hexamethylene bismuth Amine carbamates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com