Petroleum drill pipe joint wooden packaging box based on smooth surface side rolling principle

A technology for oil drill pipe joints and drill pipe joints, which is applied in the direction of using tools for cleaning methods, internal accessories, chemical instruments and methods, etc., and can solve problems such as high risk, easy hand slipping, and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

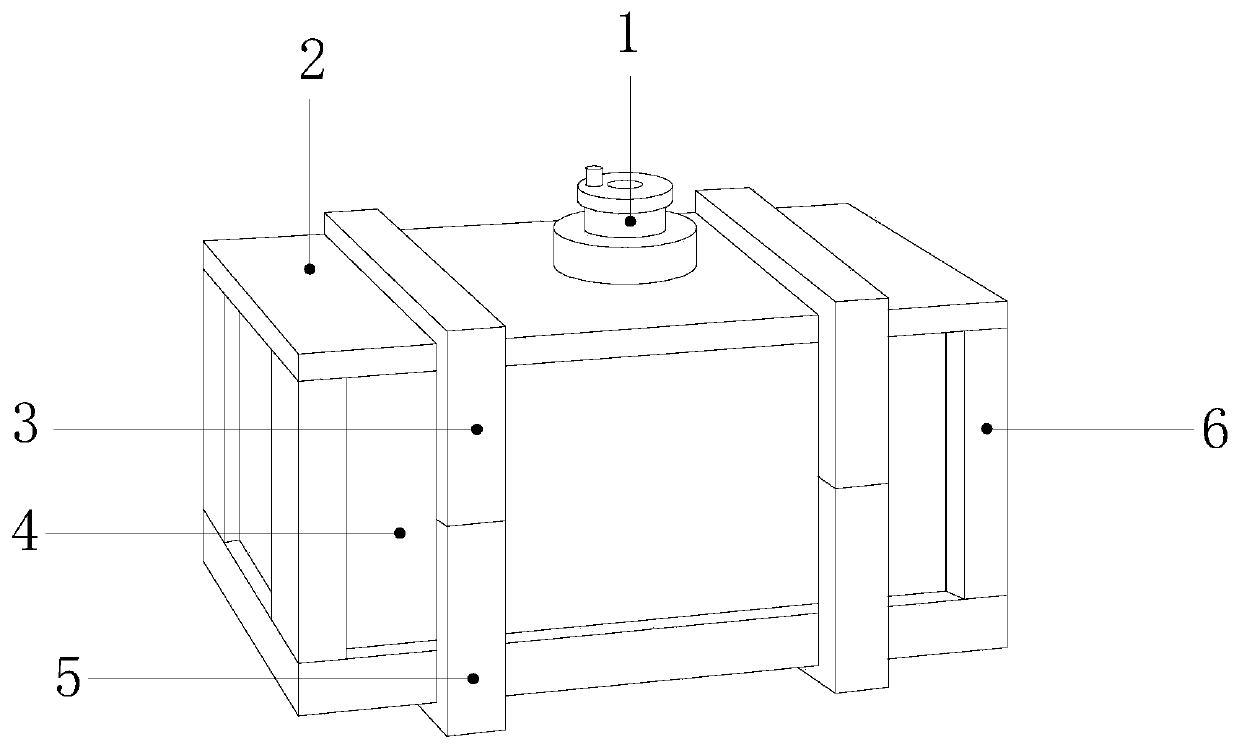

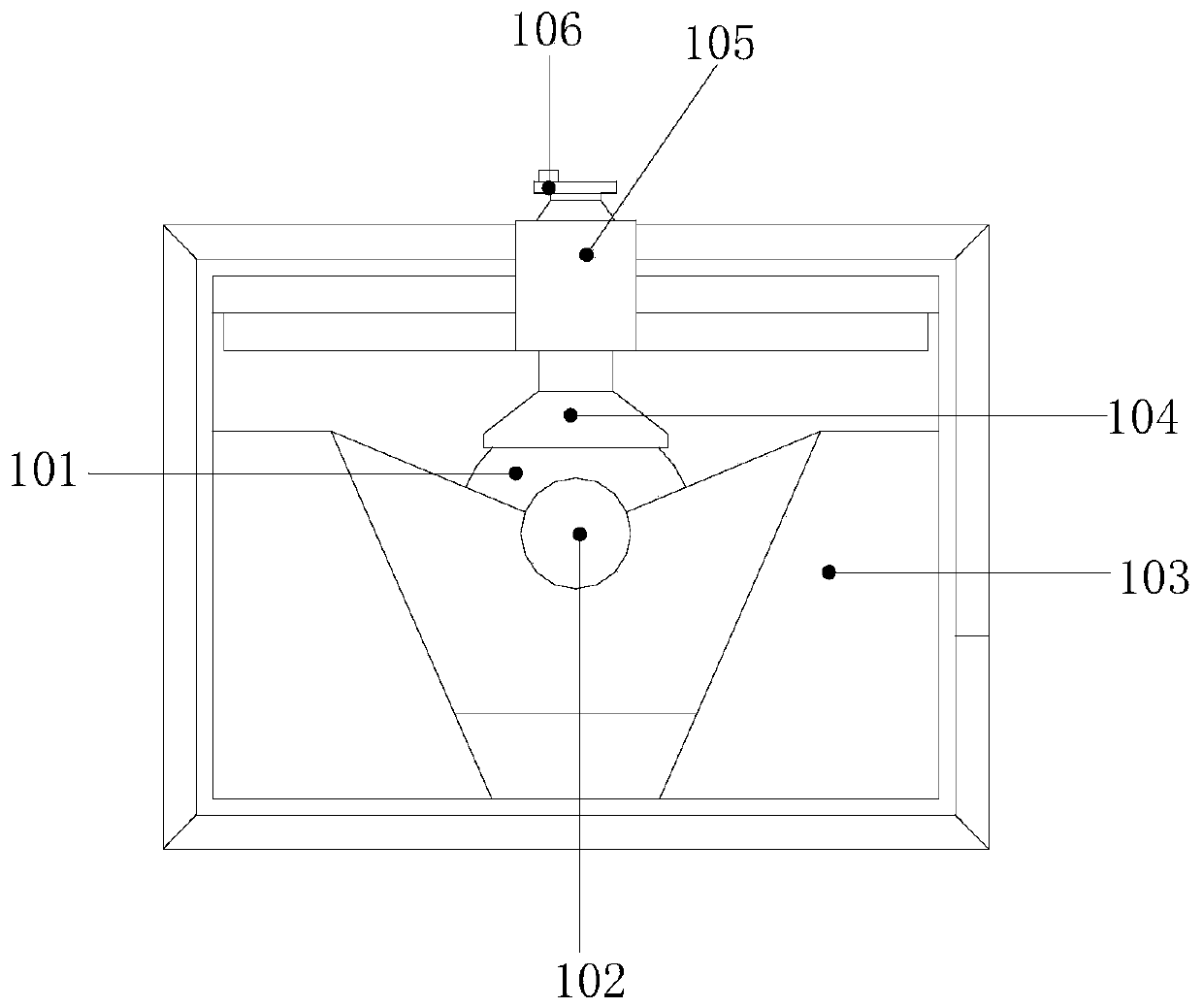

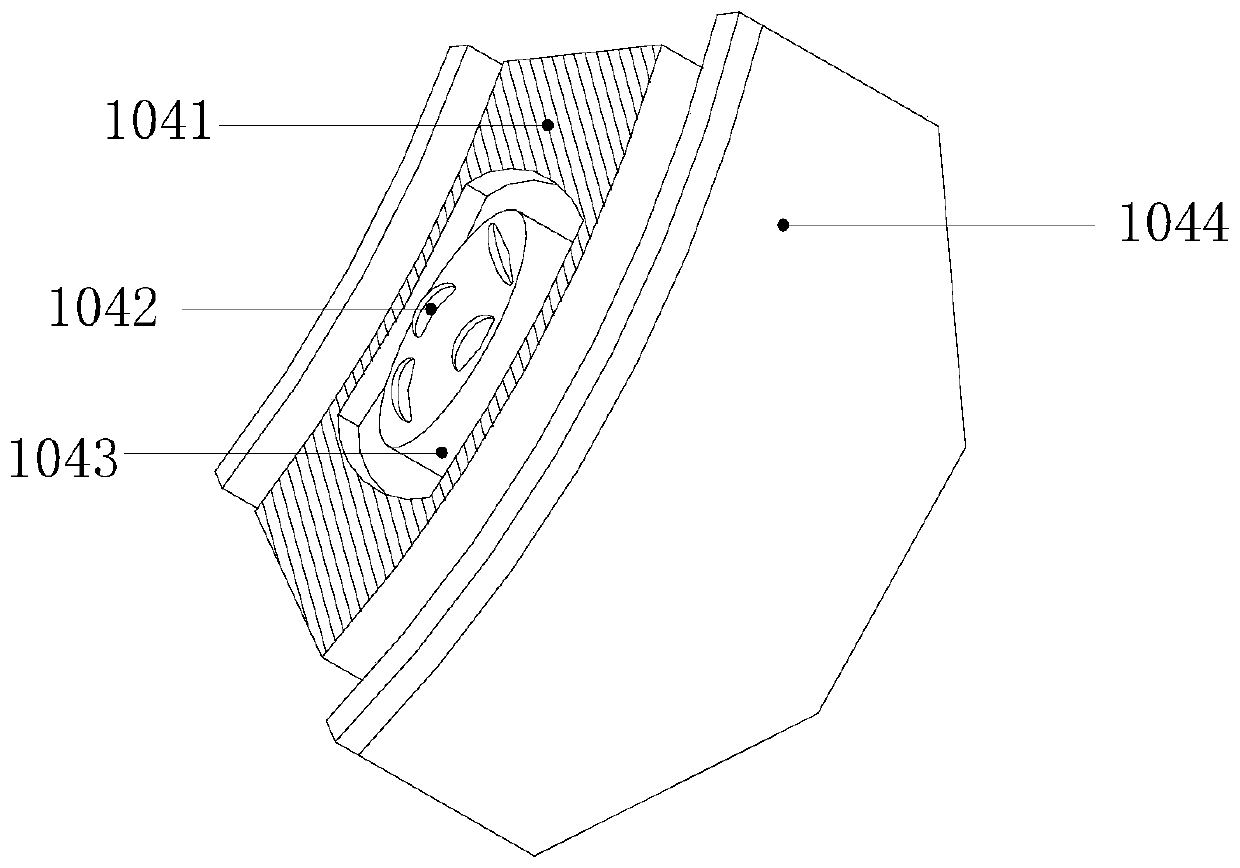

[0027] see Figure 1-Figure 6 , the present invention provides a wooden packaging box for oil drill pipe joints based on the principle of side milling smooth surface, the structure of which includes a side mill 1, a sealing cover plate 2, a fixing clip 3, a loading box body 4, a bottom frame 5, a fastening Strip 6, the fastening strip 6 is provided with more than two, and is installed on the four corners of the side of the loading box 4 by buckling, and the two ends of the bottom of the loading box 4 are connected with the bottom frame 5 by buckling, so The upper ends of the bottom frame 5 are respectively buckled with the slots of the fixing clips 3. There are two fixing clips 3, which are installed on the left and right ends of the sealing cover plate 2 respectively. The middle part of the sealing cover plate 2 is provided with The groove of the side roller 1, the top rear end of the loading box 4 and the rear end of the sealing cover 2 are connected by a hinge, and the dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com