Ultrasonic lead-acid storage battery

A lead-acid battery, ultrasonic technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery repair/maintenance, etc., can solve the problems of non-environmental protection, pollution of the natural environment, lead-acid battery scrapping, etc., to achieve charging and discharging performance The effect of stability, extended service life and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

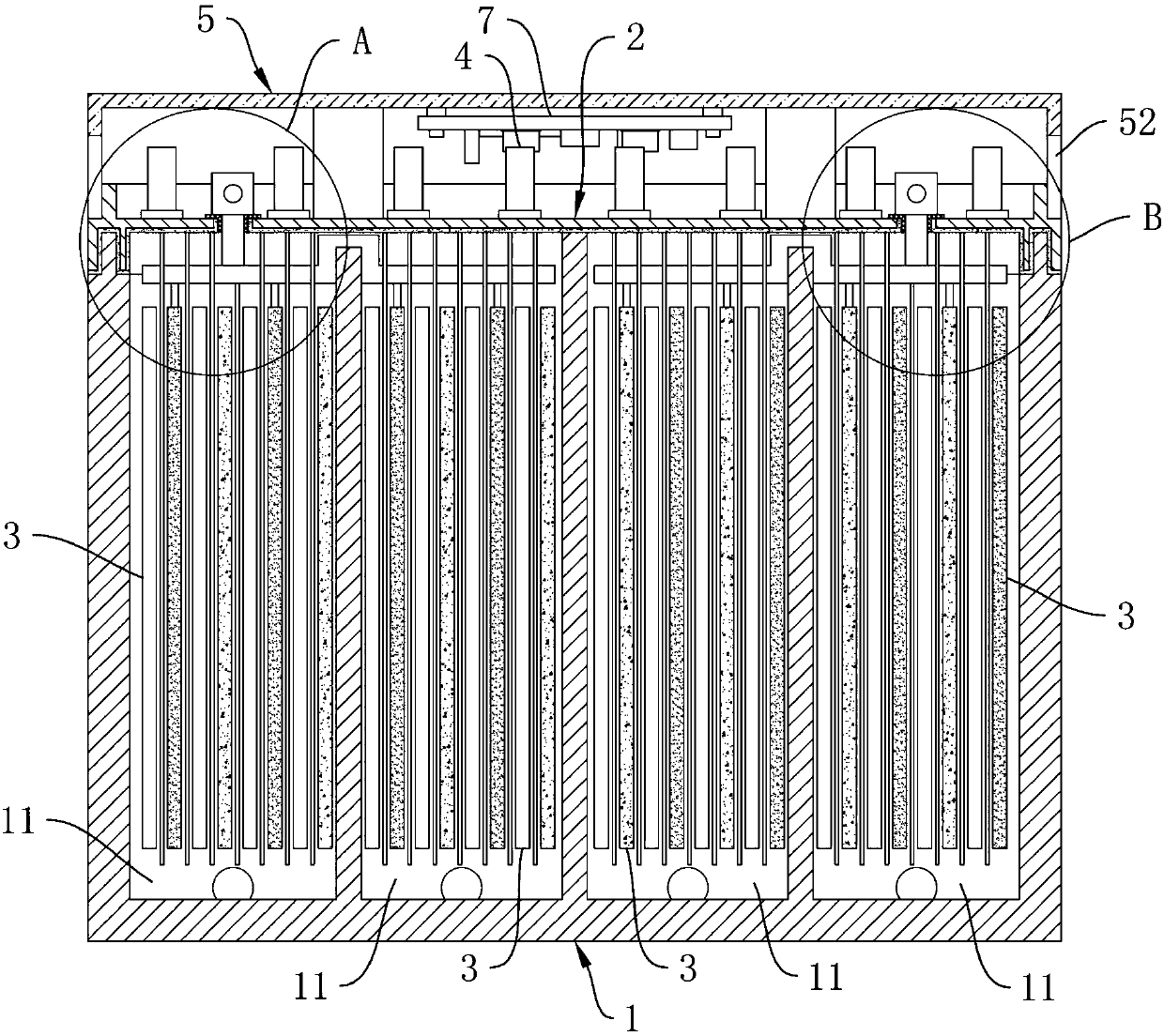

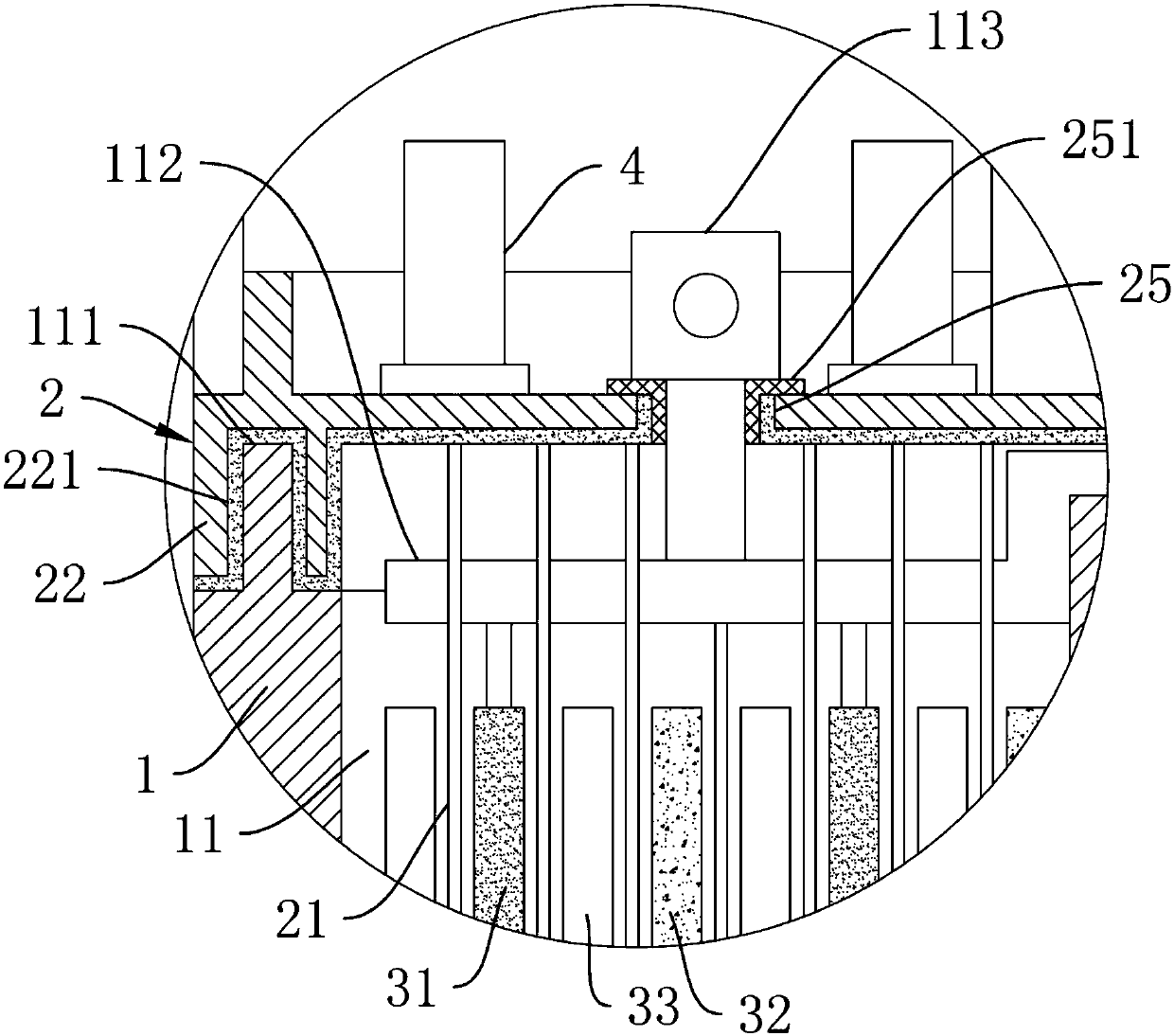

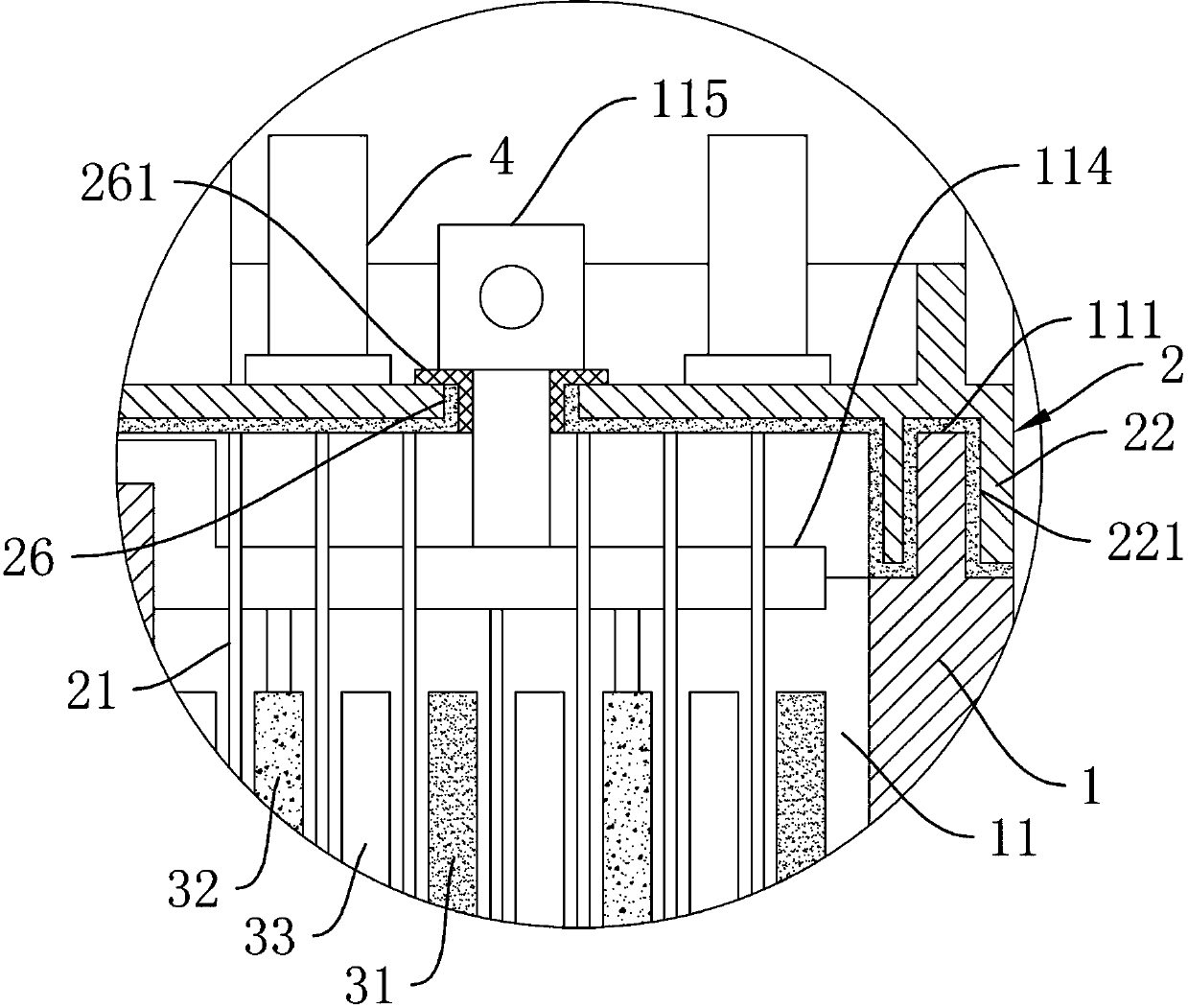

[0025] Such as figure 1 As shown, a kind of ultrasonic lead-acid storage battery of the present invention comprises battery casing 1, battery cover 2, cluster group 3, at least one ultrasonic transducer 4, wherein, as Figure 4 As shown, the top of the battery case 1 is provided with an accommodating chamber 11, and the outer wall of the battery case 1 is provided with a drain port 12 penetrating to the accommodating chamber 11, and a sealing plug 13 is provided in the drain port 12; Figure 1 to Figure 4 As shown, the bottom of the battery cover 2 is provided with some insulating and corrosion-resistant vibrating bars 21; Figure 1 to Figure 4 As shown, the cluster group 3 includes a number of positive plates 31, a number of negative plates 32, and a number of separators 33, each positive plate 31 and negative plate 32 are stacked in an interlaced manner, and each separator 33 is respectively arranged on the positive plate 31 and the negative plate. between the plates 32; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com