Cold-rolled low-alloy high-strength steel for automobiles and production method thereof

A low-alloy, high-strength, production method technology, applied in metal material coating process, coating, hot-dip plating process, etc., can solve the problem of insufficient product flexibility, achieve guaranteed performance, reduce production costs, and ensure flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

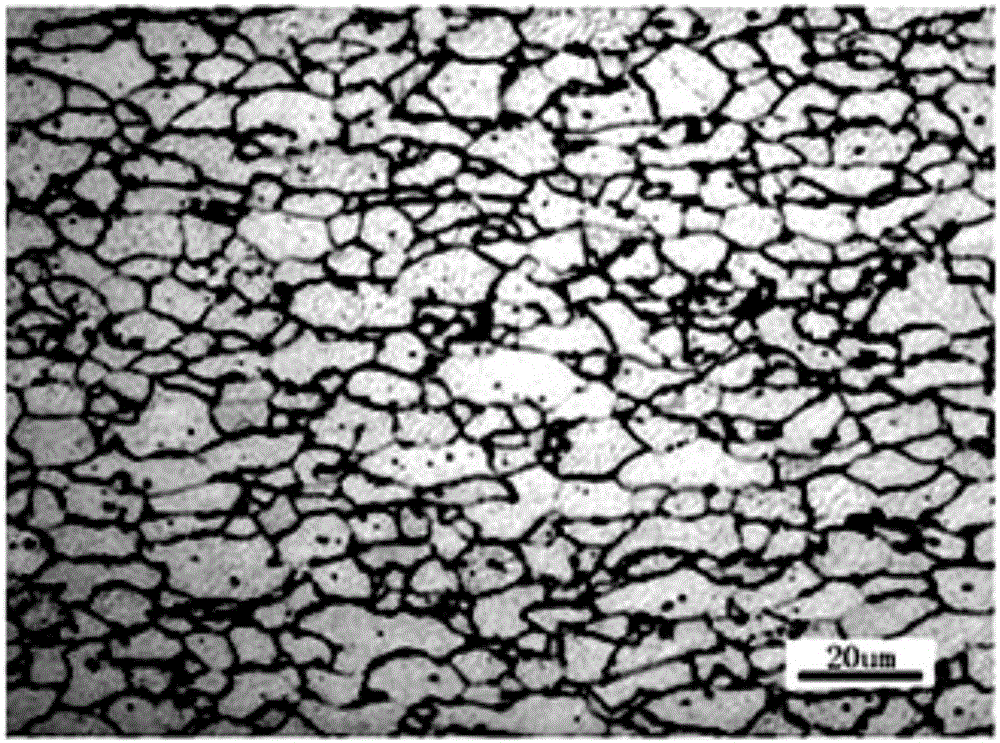

Image

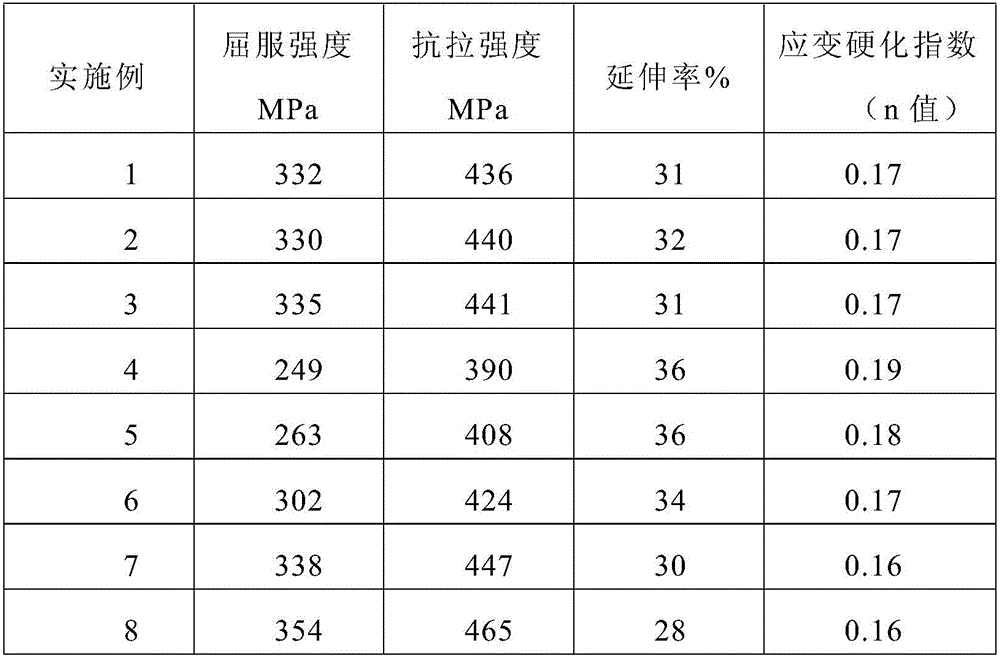

Examples

Embodiment 1

[0042] The hot-rolled annealed sheet with a thickness of 2.8 mm has the following components and mass percentages: C: 0.075, Si: 0.044, Mn: 0.45, P: 0.02, S: 0.008, Nb: 0.015, Al: 0.040, N: 0.002, The balance is Fe and unavoidable impurities.

[0043] The preparation method sequentially produces high-strength steel through blast furnace molten iron, molten iron desulfurization, converter smelting, RH vacuum treatment, continuous casting, conventional hot rolling, pickling cold continuous rolling, continuous annealing, leveling and tension leveling, wherein,

[0044] The values of the main process parameters: the heating temperature of conventional hot rolling is 1150°C, the finishing temperature is 870°C, and when the hot rolling thickness is 2.8mm, the coiling temperature is 690°C; When the reduction rate is 77%, the continuous annealing temperature is controlled at 780 ° C; the total elongation rate of the mode of the leveling and tension leveling process is 1.3%;

[0045...

Embodiment 2

[0047] The hot-rolled annealed sheet with a thickness of 3.2 mm has the following components and mass percentages: C: 0.075, Si: 0.044, Mn: 0.45, P: 0.02, S: 0.008, Nb: 0.015, Al: 0.040, N: 0.002, The balance is Fe and unavoidable impurities.

[0048] The preparation method sequentially produces high-strength steel through blast furnace molten iron, molten iron desulfurization, converter smelting, RH vacuum treatment, continuous casting, conventional hot rolling, pickling cold continuous rolling, continuous annealing, leveling and tension leveling, wherein,

[0049] The values of the main process parameters: the heating temperature of conventional hot rolling is 1150°C, the finishing temperature is 870°C, and when the hot rolling thickness is 3.2mm, the coiling temperature is 670°C; When the reduction rate is 70%, the continuous annealing temperature is controlled at 780°C; the total elongation of the mode of the leveling and tension leveling process is 1.3%;

[0050] Accor...

Embodiment 3

[0052] The hot-rolled annealed sheet with a thickness of 5.5 mm has the following components and mass percentages: C: 0.075, Si: 0.044, Mn: 0.45, P: 0.02, S: 0.008, Nb: 0.015, Al: 0.040, N: 0.002, The balance is Fe and unavoidable impurities.

[0053] The preparation method sequentially produces high-strength steel through blast furnace molten iron, molten iron desulfurization, converter smelting, RH vacuum treatment, continuous casting, conventional hot rolling, pickling cold continuous rolling, continuous annealing, leveling and tension leveling, wherein,

[0054] The values of the main process parameters: the heating temperature of conventional hot rolling is 1150°C, the finishing temperature is 870°C, and when the hot rolling thickness is 5.5mm, the coiling temperature is 650°C; When the reduction rate is 60%, the continuous annealing temperature is controlled at 780 ° C; the total elongation of the mode of the leveling and tension leveling process is 1.4%;

[0055] Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com