Preparation device of aircraft composite material fuselage wall panels and preparation method thereof

A fuselage wall panel and preparation device technology, which is applied in the field of aviation manufacturing, can solve the problems of poor positioning accuracy, difficult positioning and precision control of hat-shaped long truss combined positioning, and achieves reliable layout, is beneficial to laying operations, and reduces overshadowing. The effect of horn rich ester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

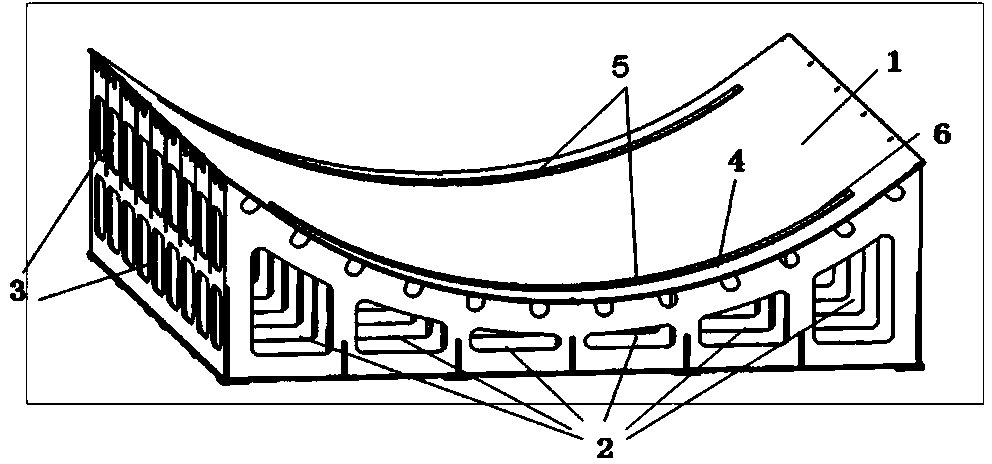

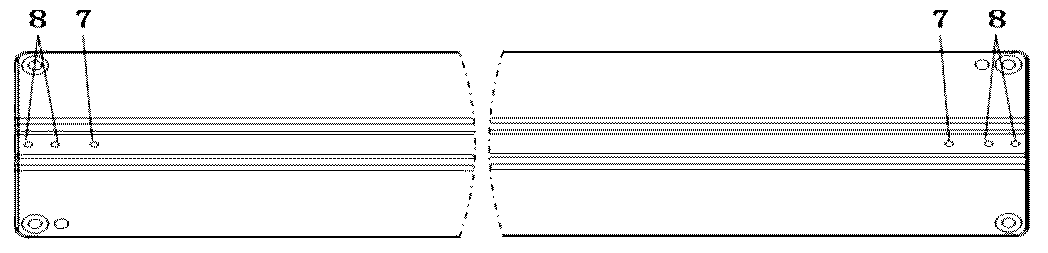

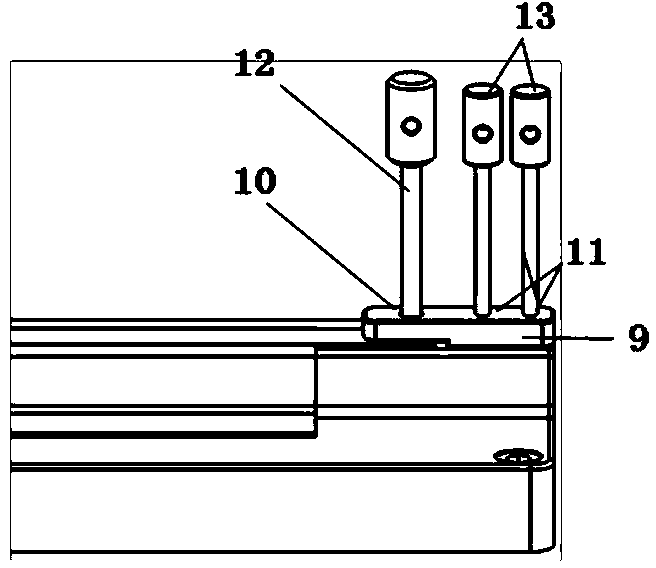

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. The preparation device includes a skin mold ( figure 1 ), hat-shaped stringer mold ( figure 2 ) and truss positioning tooling ( image 3 ), skin mold ( figure 1 ) is the negative mold, and the skin mold ( figure 1 ) is the curved surface 1 corresponding to the outer surface of the fuselage, and the skin mold ( figure 1 ) a row of ventilation holes 2 are uniformly opened along the side of the vertical stringer direction, and a row of ventilation holes 3 are evenly opened in the height direction of the skin mold along the side of the stringer direction, and the side surfaces of the skin mold along the stringer direction are Ventilation holes 3 are evenly opened in the length direction, and the skin mold ( figure 1 ) is provided with a positioning hole 4 at the position of each long stringer on both sides of the wall plate along the stringer direction; the hat-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com