Cleaning device of polishing pad finishing disc

A technology for cleaning devices and dressing discs, which is applied to grinding/polishing equipment, abrasive surface adjustment devices, cleaning methods using tools, etc., can solve problems such as weak cleaning effect, to ensure the surface, avoid abnormal grinding rate, and maintain the process Stability and Product Safety Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

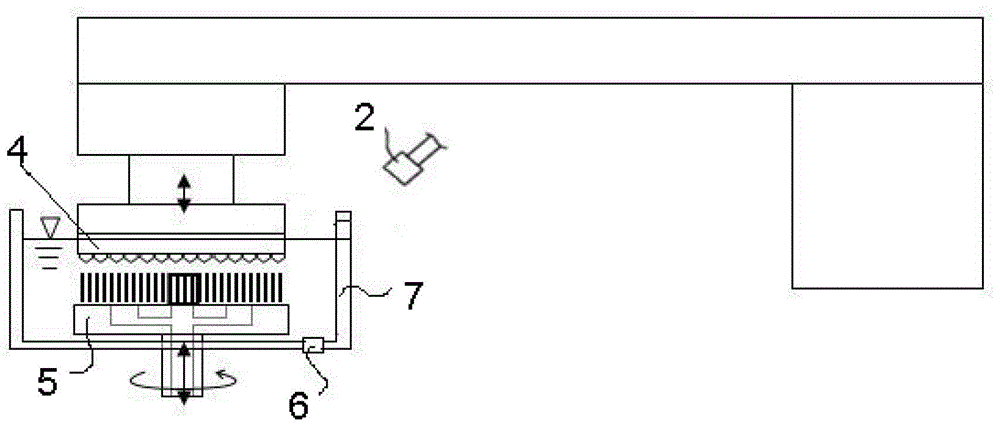

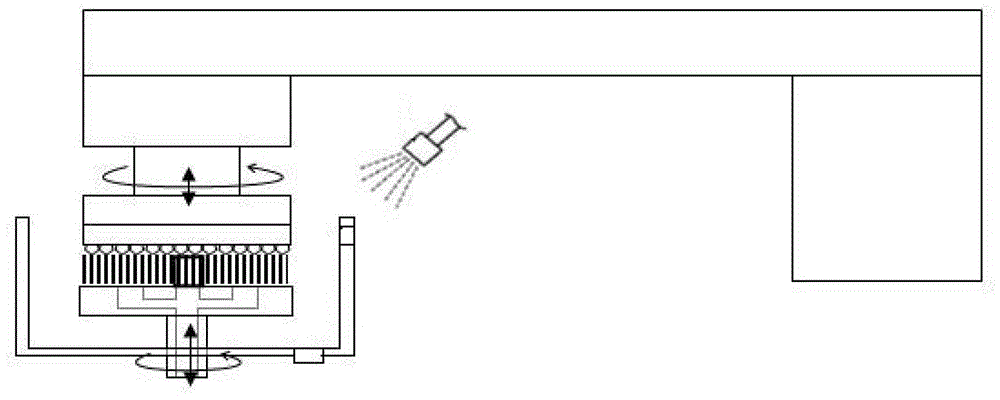

[0065] Cleaning devices for polishing pad conditioning discs, such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, it includes a cleaning cup 7, a cleaning brush carrying device 5, a cleaning brush 8, a central nozzle 10, a first valve, a power pure water pipeline, a drive shaft, a bearing, a cylinder, a motor, and a controller;

[0066] The cleaning brush 8 is fixed on the top surface of the cleaning brush carrying device 5;

[0067] The upper end of the bearing is fixed on the middle part of the bottom surface of the cleaning brush carrying device 5, and the lower end passes through the bottom of the cleaning cup 7 and is connected to the cylinder;

[0068] The cylinder is used to drive the bearing to move up and down;

[0069] The drive shaft is provided with a through hole along the axis;

[0070] The drive shaft is pivotally fixed in the bearing, the upper end passes through the center of the cleaning brush carrying device 5 and is fixed togeth...

Embodiment 2

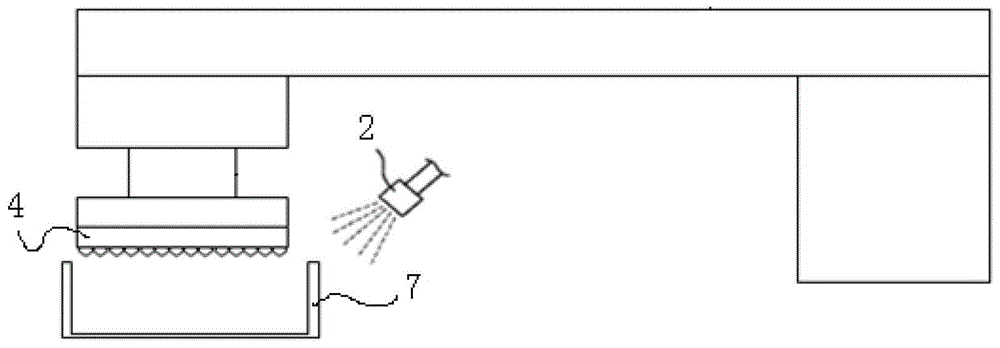

[0078] The cleaning device based on the polishing pad conditioning disc of Embodiment 1 also includes an edge nozzle 2 and a second valve;

[0079] The edge nozzle 2 is arranged above the outer side of the cleaning cup 7 for spraying divergent water mist;

[0080] One end of the second valve communicates with the edge nozzle 2, and the other end communicates with the power pure water pipeline;

[0081] The controller is further configured to control the action of the second valve according to the cleaning trigger signal and the cleaning end signal.

[0082] The deionized water sprayed by the edge nozzle 2 can clean the side of the polishing pad conditioning disc.

Embodiment 3

[0084] Based on the cleaning device of the polishing pad conditioning disc of the second embodiment, the side wall of the cleaning cup 7 is provided with an overflow hole; the bottom of the cleaning cup 7 is provided with a drain valve 6;

[0085] The drain valve 6 is connected to the inside of the cleaning cup 7 at the upper end, and connected to the outside of the cleaning cup 7 at the lower end;

[0086] The controller is also used to control the action of the drain valve 6 according to the cleaning trigger signal and the cleaning end signal.

[0087] In the cleaning device of the polishing pad dressing disc in the third embodiment, the setting of the overflow hole can limit the height of the liquid level in the cleaning cup, and the setting of the drain valve can drain the liquid in the cleaning cup.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com