Wedge unit and braking device

A braking device, wedge-shaped technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve problems such as limiting the service life of rollers or actuating pistons and/or wedges, hindering brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Throughout the figures, identical or equivalent elements are marked with the same reference numerals.

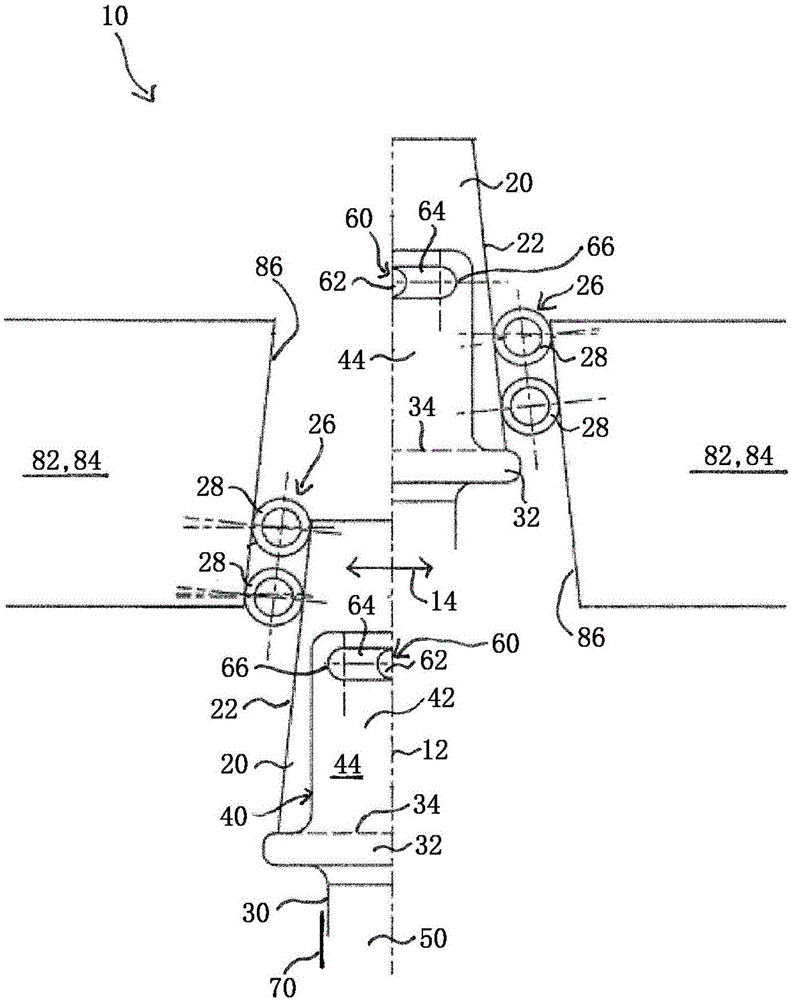

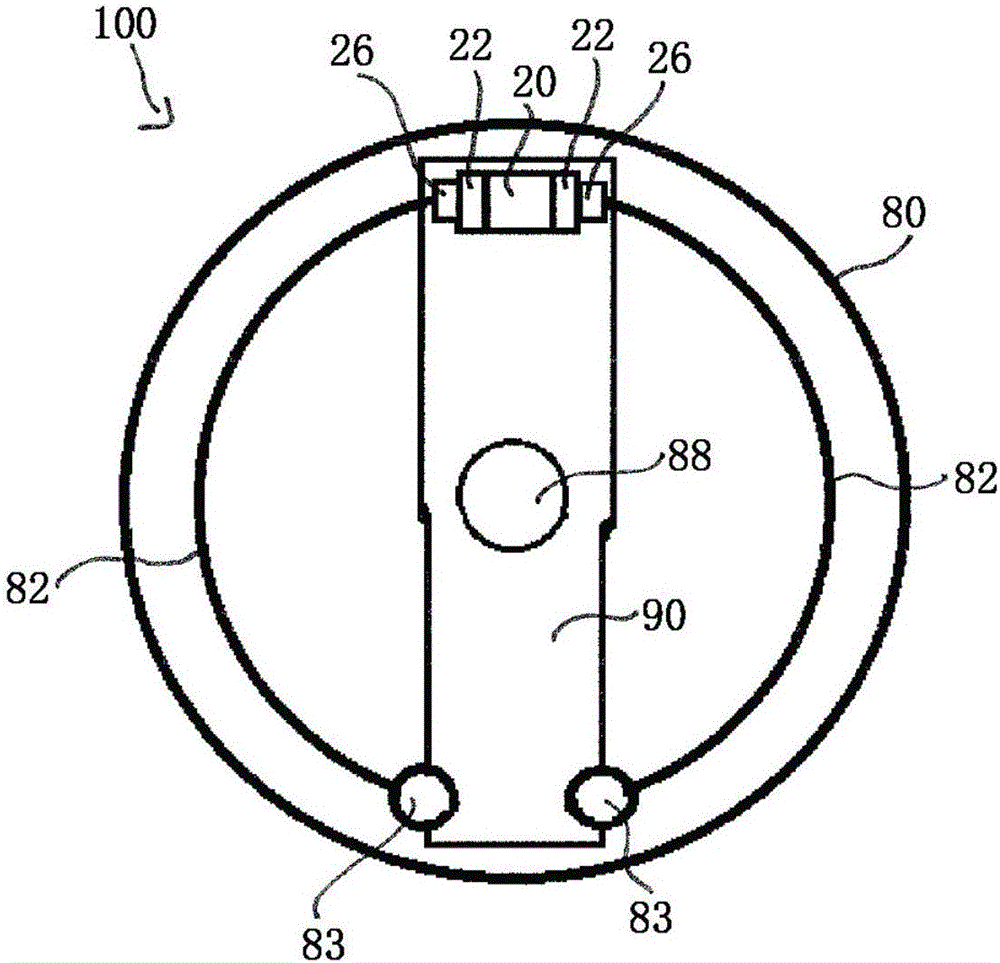

[0029] figure 1A wedge unit 10 of a braking device 100 according to the invention is shown. The wedge unit 10 comprises a wedge 20 whose center plane (symmetry plane) is oriented parallel to the actuation direction 12 (axial movement direction, lifting direction). Furthermore, the multi-part wedge unit 10 also comprises an adjustment element 30 for displacing the wedge 20 in the actuation direction 12 . The adjusting element 30 comprises a pressure plate 32 for displacing the wedge 20 substantially in the actuating direction 12 so that the braking device 100 can be moved from the unloaded position into the braking position. To this end, the pressure plate 32 comprises a pressure surface 34 extending substantially perpendicularly to the actuation direction 12 . The pressure surface 34 cooperates with a corresponding opposing pressure surface of the wedge 20 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com