Window glass lifting system

A technology of window glass and lifting system, which is applied to door/window accessories, the arrangement of wing sash, door sash, etc., can solve the problem of curved window glass difficult to lift smoothly, so as to avoid difficulty in lifting and improve comfort. , the effect of beautiful shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

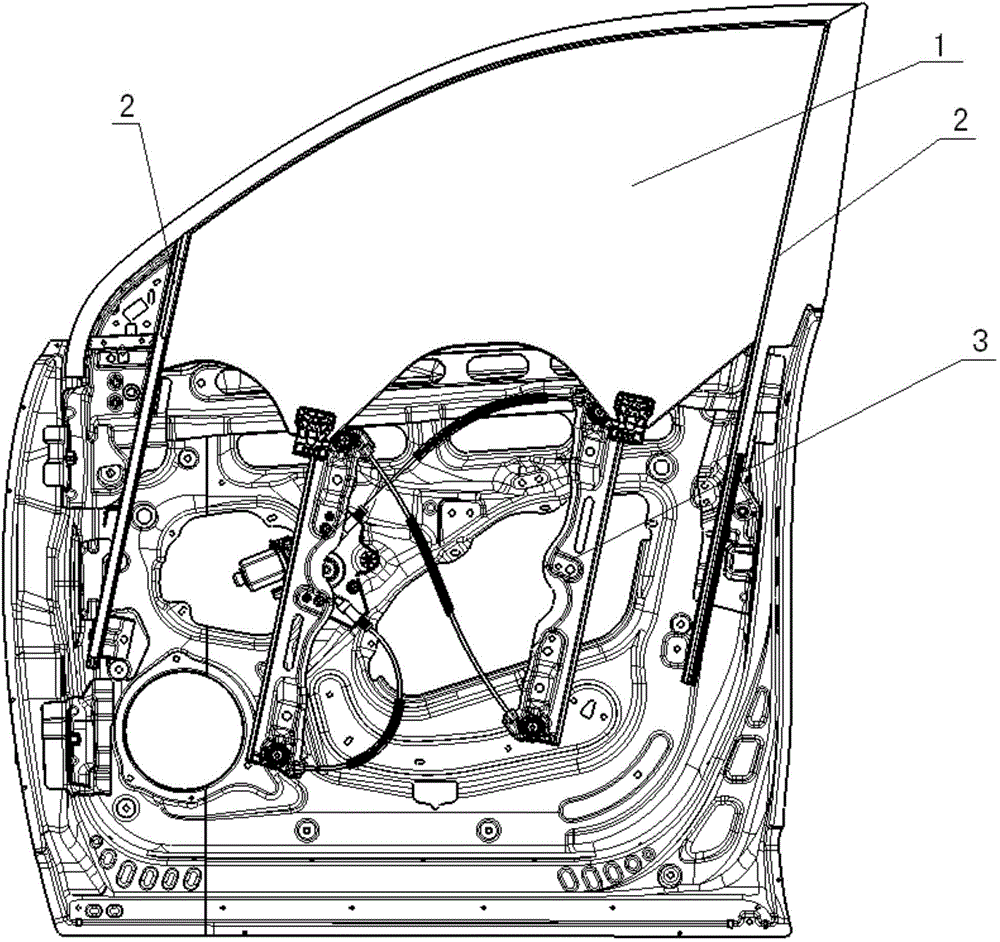

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a vehicle window lifting system, the vehicle window lifting system includes: a vehicle window 1, a glass regulator 3 and two parallel guide rails 2, the two guide rails 2 are respectively Installed on the opposite sides of the window, the window glass 1 is located between the two guide rails 2, and the opposite sides of the window glass 1 are snapped into the two guide rails 2 respectively. The lifter 3 is connected to the window glass 1, and the glass lifter 3 is used to drive the window glass 1 to slide along the two guide rails 2,

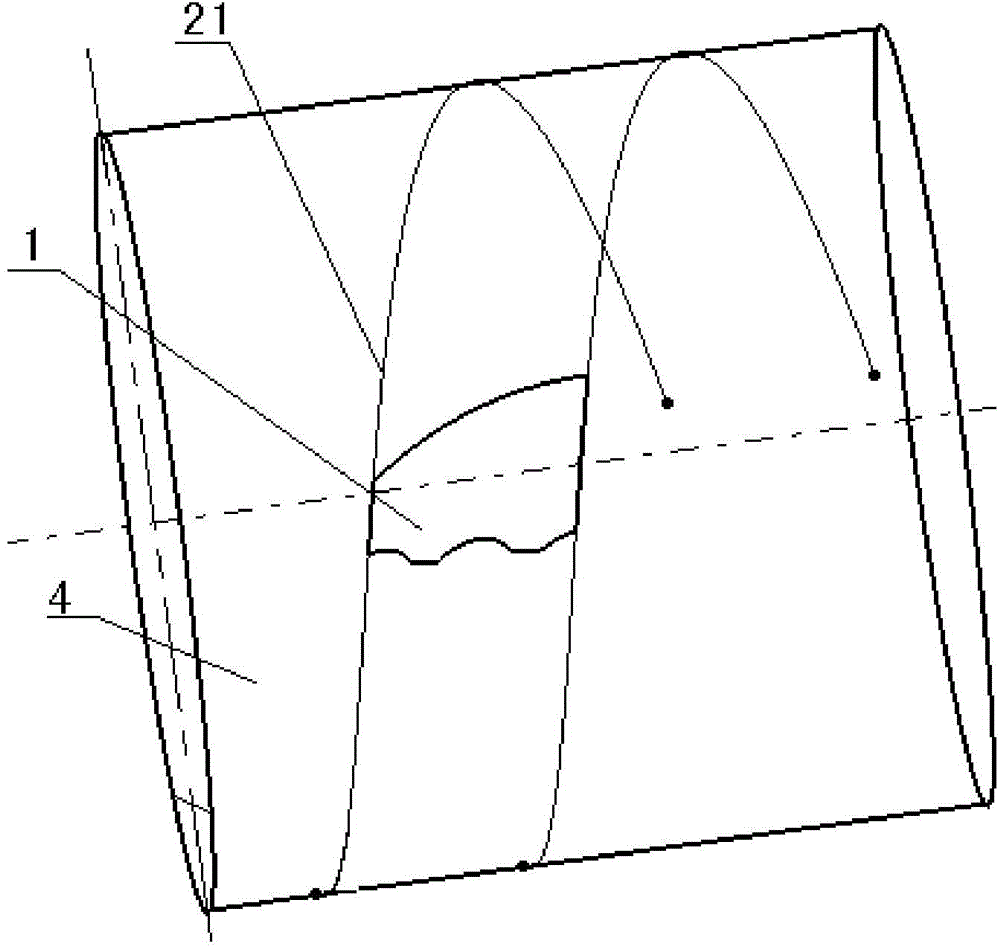

[0028] Such as figure 2 As shown, the vehicle window glass 1 is a curved surface structure, the trajectory lines of the two guide rails 2 are both curves, and the vehicle window glass 1 and the trajectory lines of the two guide rails 2 are located on the same curved surface.

[0029] Wherein, window lifter 3 is prior art, is made up of parts such as motor, reel...

Embodiment 2

[0032] Such as figure 1 As shown, another embodiment of the present invention provides a vehicle window glass lifting system, the vehicle window glass lifting system includes: a vehicle window glass 1, a glass regulator 3 and two parallel guide rails 2, the two guide rails 2 are respectively installed on opposite sides of the vehicle window, the vehicle window glass 1 is located between the two guide rails 2, and the opposite sides of the vehicle window glass 1 are snapped into the two guide rails 2 respectively, so that The glass lifter 3 is connected to the vehicle window glass 1, and the glass lifter 3 is used to drive the vehicle window glass 1 to slide along the two guide rails 2,

[0033] Such as figure 2 As shown, the vehicle window glass 1 is a curved surface structure, the trajectory lines of the two guide rails 2 are both curves, and the vehicle window glass 1 and the trajectory lines of the two guide rails 2 are located on the same curved surface.

[0034] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com