On-line acid blueing method for hot-rolled steel bars

An acid and bluing technology, applied in the direction of metal material coating process, can solve the problems of high cost, corrosion of steel bars, increase project cost, etc., and achieve the effect of high production efficiency, anti-corrosion, and good anti-rust and anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

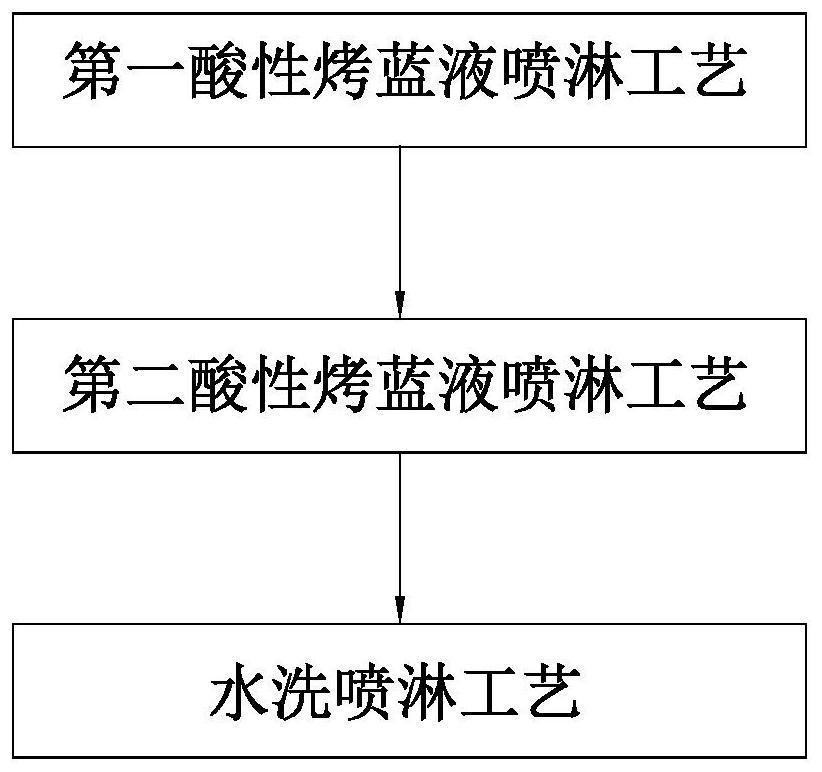

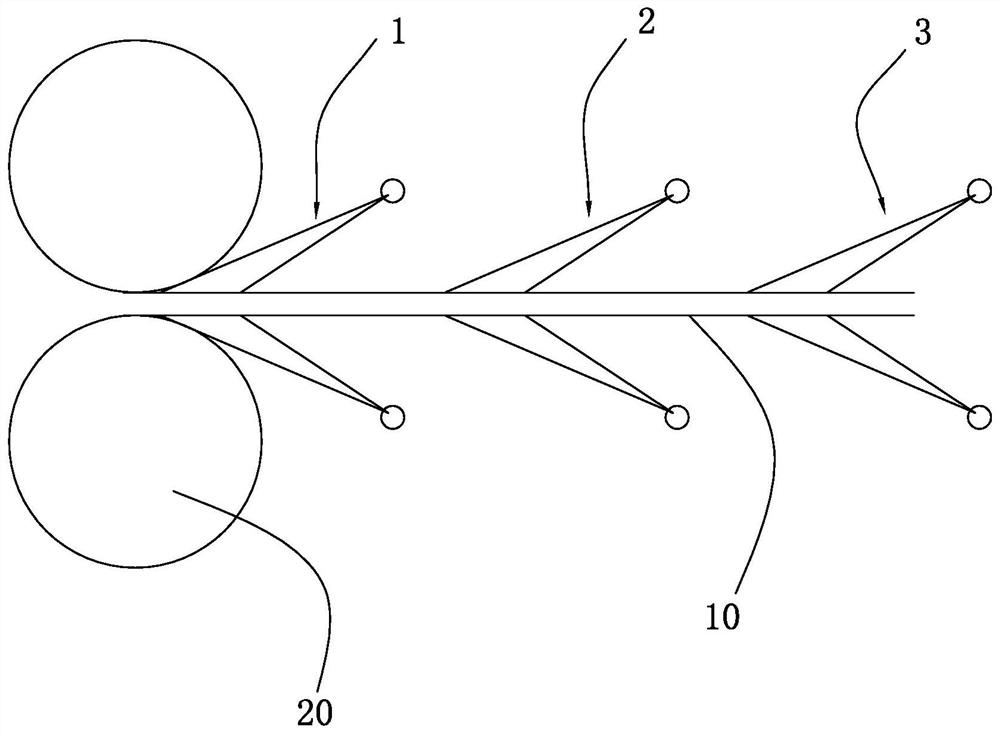

Method used

Image

Examples

Embodiment 1

[0042] Use H 3 PO 4 , Ca(NO 3 ) 2 , MnO 2 Soluble in H 2 O is configured as an acidic roasting blue solution, and H is controlled 3 PO 4 , Ca(NO 3 ) 2 , MnO 2 The mass concentrations are 4g / L, 140g / L, and 18g / L respectively; the pressure of the spraying device corresponding to the first acidic bluing liquid spray process, the second acidic bluing liquid spray process, and the washing spray process is 0.35 MPa; the temperature of the hot-rolled steel bar after the water washing and spraying process is controlled at 540±20°C. After the steel bar is dried by using the waste heat of rolling, black Fe is formed on the surface of the steel bar 3 o 4 Anti-rust film.

Embodiment 2

[0044] Use H 3 PO 4 , Ca(NO 3 ) 2 , MnO 2 Soluble in H 2 O is configured into an acidic bluing liquid, and the concentration of the bluing liquid used in the first acidic bluing liquid spray process is: H 3 PO 4 The mass concentration is 18g / L, Ca(NO 3 ) 2 The mass concentration is 70g / L, MnO 2 The mass concentration is 13g / L; the concentration of the bluing liquid used in the second acidic bluing liquid spray process is: H 3 PO 4 The mass concentration is 10g / L, Ca(NO 3 ) 2 The mass concentration is 100g / L, MnO 2 The mass concentration is 12g / L; the pressure of the spraying device is controlled to 0.3MPa; the temperature of the hot-rolled steel bars after washing and spraying is controlled at 560±20°C. After the steel bar is dried by using the waste heat of rolling, black Fe is formed on the surface of the steel bar 3 o 4 Anti-rust film.

[0045] In order to further illustrate the advantages of the on-line acid blueing method for hot-rolled steel bars provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com