A kind of production method of galvanized steel strip for packaging

A production method and packaging technology, applied in packaging, transportation, packaging, coating, etc., can solve problems such as pollution and production costs, and achieve the effects of easy coating quality, convenient operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

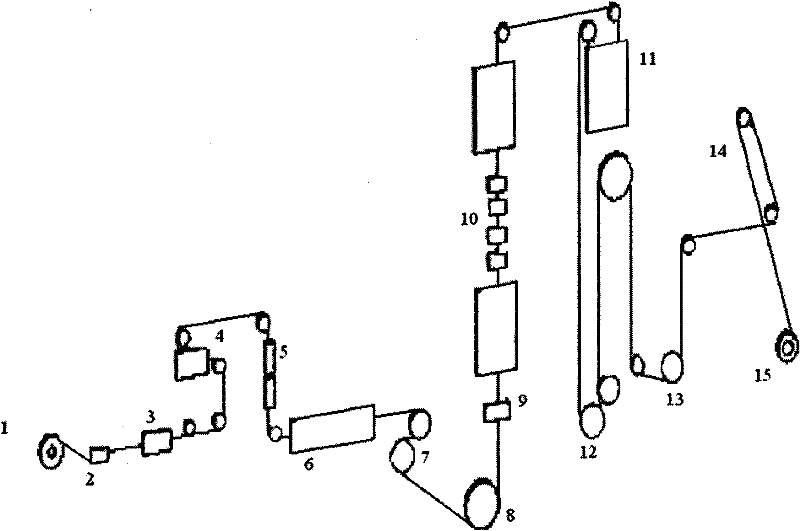

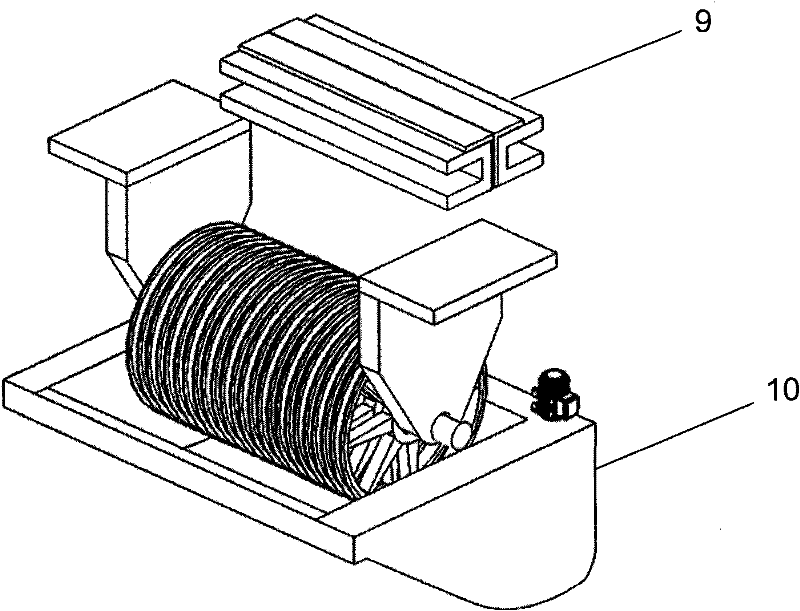

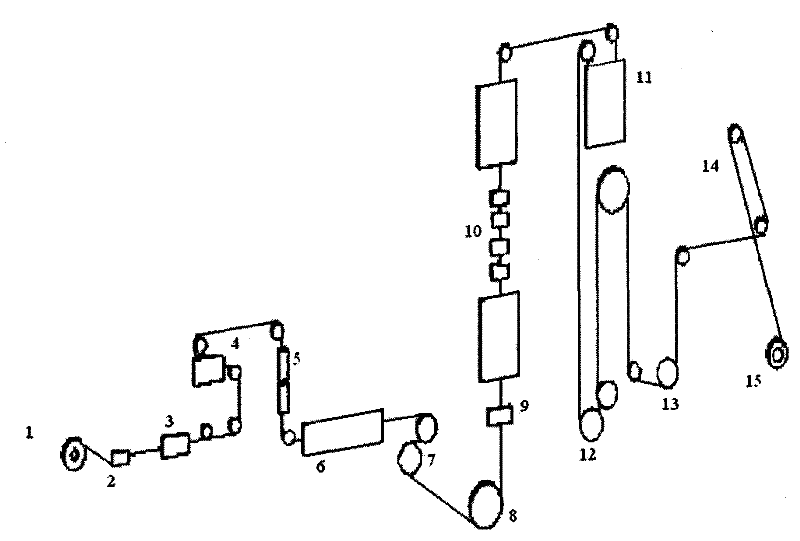

Method used

Image

Examples

Embodiment 1

[0051] The cold-rolled coil with the specification of 0.8×389mm is selected as the raw material. The operating speed of the unit is 20m / min, the bluing temperature is 320°C, and the mass ratio of the original paint to water is 1:3. The raw material is slit into strips of 0.8×31.75mm after slitting by discs, a total of 12 strips, which are produced according to the above-mentioned process flow.

[0052] The surface of the finished product is bright silver, evenly coated with zinc, glossy, no background color of the steel strip, the film thickness is about 5μm, the tensile strength is above 800MPa, and the elongation is greater than 6%.

[0053] Example 2

Embodiment 2

[0055] The cold-rolled coil with the specification of 0.8×389mm is selected as the raw material. The operating speed of the unit is 25m / min, the bluing temperature is 320°C, and the mass ratio of the original paint to water is 1:3. The raw material is slit into strips of 0.8×31.75mm after slitting by discs, a total of 12 strips, which are produced according to the above-mentioned process flow.

[0056] The surface of the finished product is silver-white, evenly coated with zinc, and has glossiness. There is no background color of the steel strip. The film thickness is about 5 μm, the tensile strength is above 800MPa, and the elongation is greater than 6%.

[0057] Example 3

Embodiment 3

[0059] The cold-rolled coil with the specification of 0.8×389mm is selected as the raw material. The operating speed of the unit is 30m / min, the bluing temperature is 325°C, and the mass ratio of the original paint to water is 1:3. The raw material is slit into strips of 0.8×31.75mm after slitting by discs, a total of 12 strips, which are produced according to the above-mentioned process flow.

[0060] The surface of the finished product is silver-white, evenly coated with zinc, and the background color of the steel strip can be seen slightly. The film thickness is about 3μm, the tensile strength is above 800MPa, and the elongation is greater than 6%.

[0061] The mechanical property test of the steel strip in the above examples was carried out on the XYA105C (CMT5105) microcomputer universal tensile testing machine in the laboratory of Shanghai Baosteel Packaging Steel Strip Co., Ltd., and the sample adopts a fully rectangular cross-sectional shape without machining.

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com