A kind of 1100mpa grade high-strength strapping steel and its production method

A production method and strip steel technology, applied in the field of metallurgy, can solve the problems of lead bath environmental pollution, bluish layer easy to fall off, high annealing cost, etc., to improve product strength, save quenching or lead bath process, and improve annealing recrystallization The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

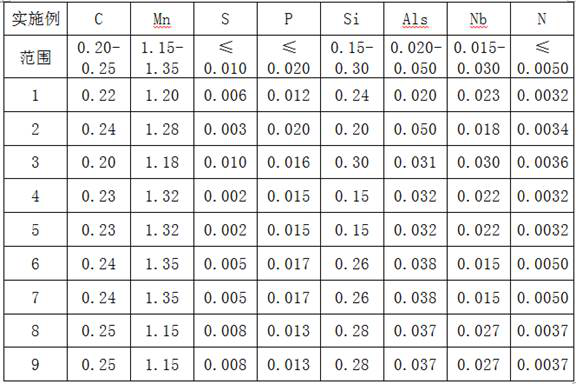

[0024] The thickness specification of the 1100MPa grade high-strength strapping steel in this embodiment is 0.90mm, and its chemical composition and mass percentage are shown in Table 1.

[0025] The production method of the 1100MPa grade high-strength strap steel of the present embodiment comprises steelmaking, continuous casting, hot rolling, cold rolling, bluing operation, and concrete process step is as follows:

[0026] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of molten steel;

[0027] (2) Continuous casting process: dynamic light reduction is adopted, the reduction amount is 3mm, and the thickness of continuous casting slab is 200mm;

[0028] (3) Hot rolling process: the heating furnace exit temperature is 1185°C, and the final rolling temperature is 835°C; the steel coil is cooled in three stages, the first stage is water-cooled to 710°C at a cooling rate of 65°C / s, and the second stage is air-cooled 3.5s, the third section ...

Embodiment 2

[0033] In this embodiment, the thickness specification of the 1100MPa grade high-strength strap steel is 1.00mm, and its chemical composition and mass percentage are shown in Table 1.

[0034] The production method of the 1100MPa grade high-strength strap steel of the present embodiment comprises steelmaking, continuous casting, hot rolling, cold rolling, bluing operation, and concrete process step is as follows:

[0035] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of molten steel;

[0036] (2) Continuous casting process: dynamic light reduction is adopted, the reduction amount is 3mm, and the thickness of continuous casting slab is 200mm;

[0037] (3) Hot rolling process: the heating furnace exit temperature is 1168°C, and the final rolling temperature is 820°C; the steel coil is cooled in three stages, the first stage is water-cooled to 720°C at a cooling rate of 82°C / s, and the second stage is air-cooled 3.5s, the third section is ...

Embodiment 3

[0042] The thickness specification of the 1100MPa grade high-strength strap steel in this embodiment is 0.80mm, and its chemical composition and mass percentage are shown in Table 1.

[0043] The production method of the 1100MPa grade high-strength strap steel of the present embodiment comprises steelmaking, continuous casting, hot rolling, cold rolling, bluing operation, and concrete process step is as follows:

[0044] (1) Steelmaking process: see Table 1 for the chemical composition and mass percentage of molten steel;

[0045] (2) Continuous casting process: dynamic light reduction is adopted, the reduction amount is 3mm, and the thickness of continuous casting slab is 200mm;

[0046] (3) Hot rolling process: the heating furnace exit temperature is 1210°C, and the final rolling temperature is 838°C; the steel coil is cooled in three stages, the first stage is water-cooled to 700°C at a cooling rate of 70°C / s, and the second stage is air-cooled 4.0s, the third section is w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com