Corrosion-resistant and rust-proof equipment for metal parts

A metal parts, corrosion-resistant technology, applied in the field of metal parts corrosion-resistant and anti-rust equipment, can solve the problems of reduced corrosion resistance and anti-rust efficiency of metal parts, reduced surface treatment efficiency of metal parts, increased staff workload, etc., to improve the smoothness , improve the grinding efficiency, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

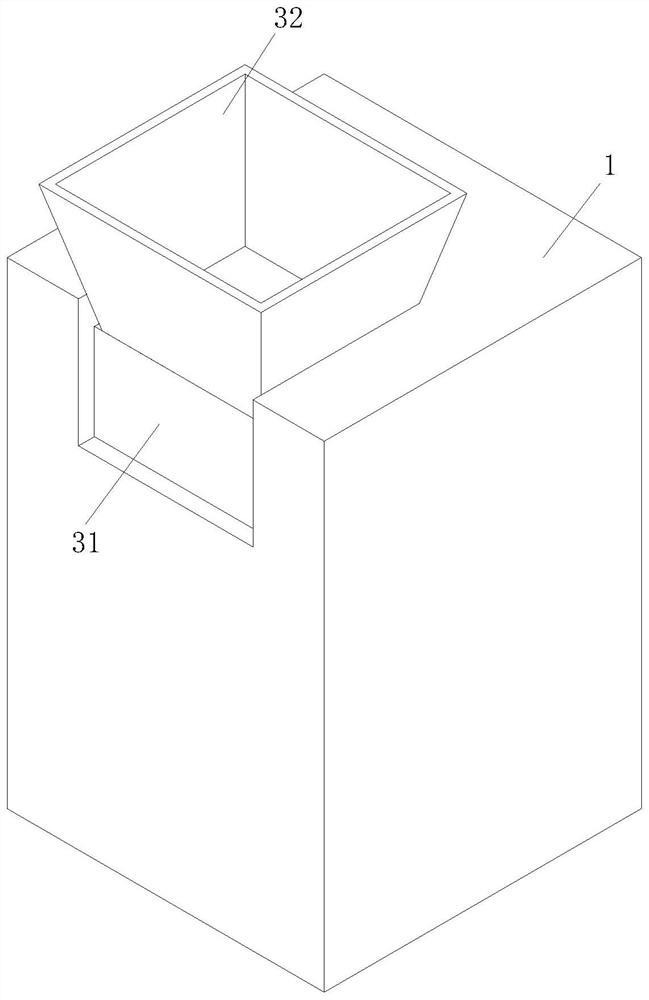

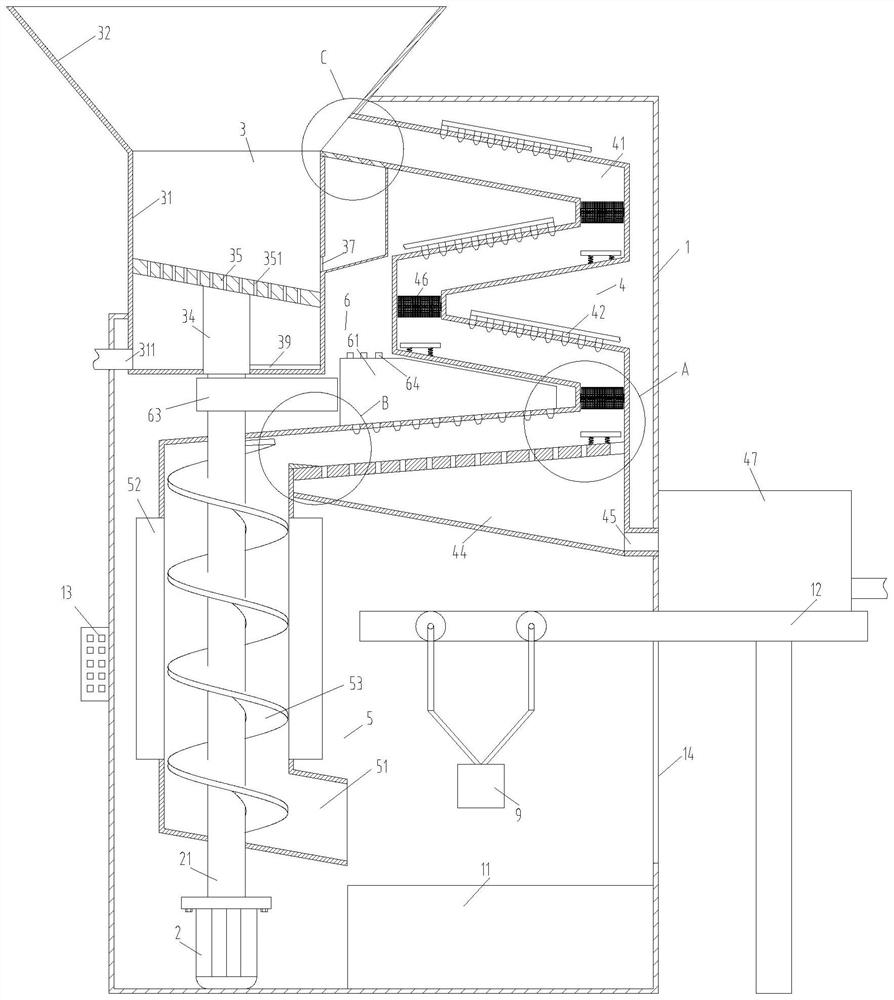

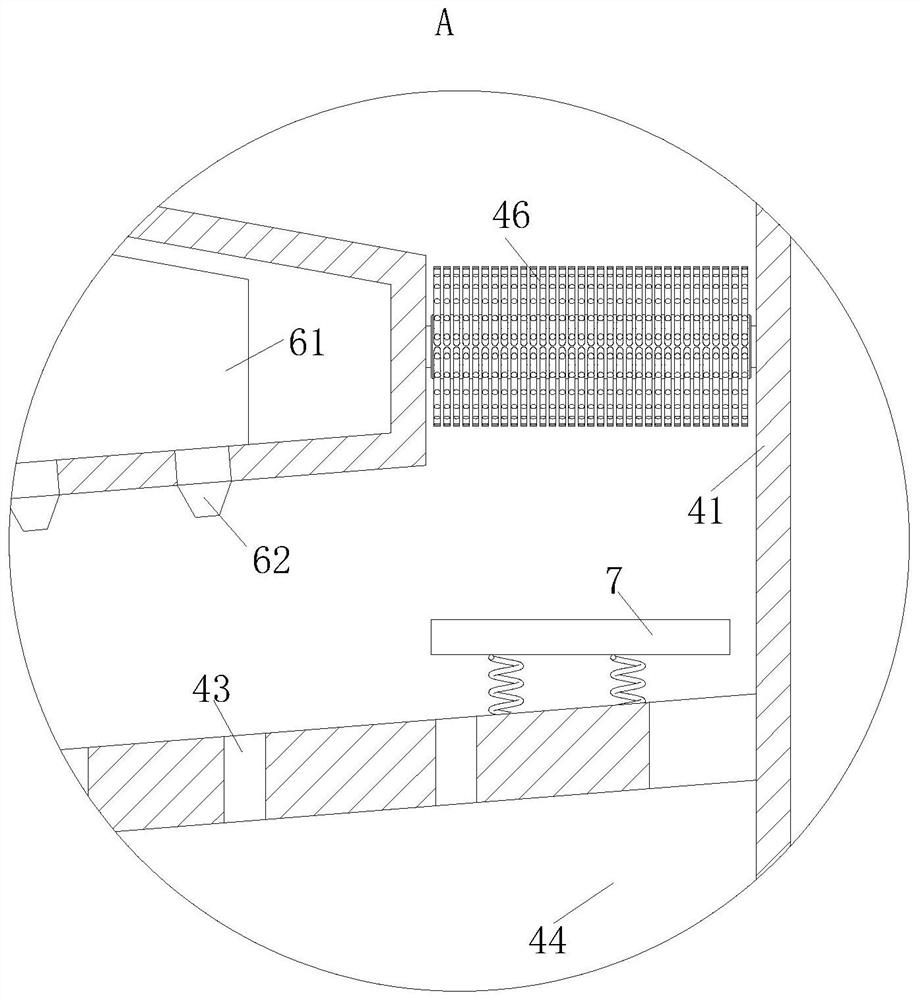

[0096] As a specific embodiment of the present invention, the derusting assembly 3 includes:

[0097] derusting bucket 31,

[0098] The derusting bucket 31 is fixedly connected to the housing 1; the bottom of the derusting bucket 31 is provided with an outlet 311; the derusting bucket 31 is connected to the washing component 4;

[0099] feed port 32,

[0100] The top of the derusting barrel 31 is provided with a feed port 32;

[0101] outlet 33,

[0102] The side wall of the derusting barrel 31 is provided with a discharge port 33;

[0103] Cylinder 34,

[0104] The cylinder 34 runs through the bottom of the derusting bucket 31 and is fixedly connected to the rotating shaft 21 and is rotatably connected to the bottom of the derusting bucket 31; the cylinder 34 is connected to an external air pump;

[0105] top plate 35,

[0106] The top plate 35 is fixedly connected to the cylinder rod in the cylinder 34; the top plate 35 is provided with a filter hole 351; the top plate...

Embodiment approach

[0161] As a specific embodiment of the present invention, the casing 1 is provided with a part outlet 14 on the side away from the drying assembly 5; , the slide rail 12 runs through the side wall of the housing 1 and is fixedly connected to the ground through a bracket; the slide rail 12 is slidably connected with an electromagnetic lifter 9; the electromagnetic lifter 9 is an electromagnetic crane structure in the prior art;

[0162] After entering the bluing treatment pool 11 for the bluing treatment, the spherical metal parts have completed the bluing treatment, the staff transmits the electric signal to the electromagnetic lifter 9 slidingly connected with the slide rail 12 through the controller, and the electromagnetic lifter 9 passes through Slide rail 12 slides to the top of the bluing treatment pool 11. At this time, the electromagnetic lifting plate of the electromagnetic crane 9 moves down to the position near the bluing treatment pool 11 liquid level. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com