A method for producing semi-process non-oriented electrical steel by endless rolling

A technology of grain-oriented electrical steel and endless rolling, applied in the field of iron and steel, can solve the problems of high cost, long process, low efficiency, etc., and achieve the effect of good magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment A method for producing semi-process non-oriented electrical steel by endless rolling

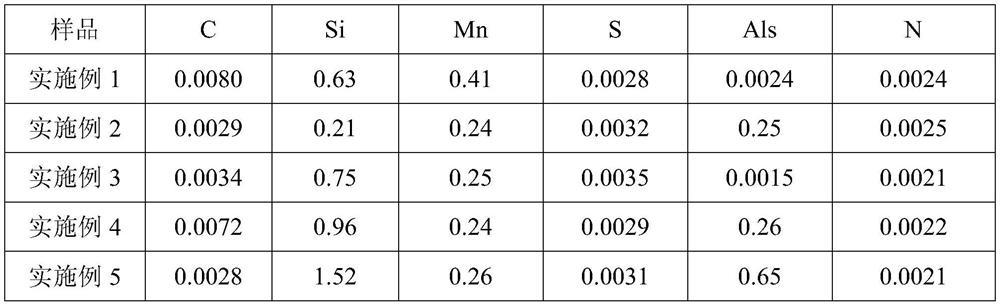

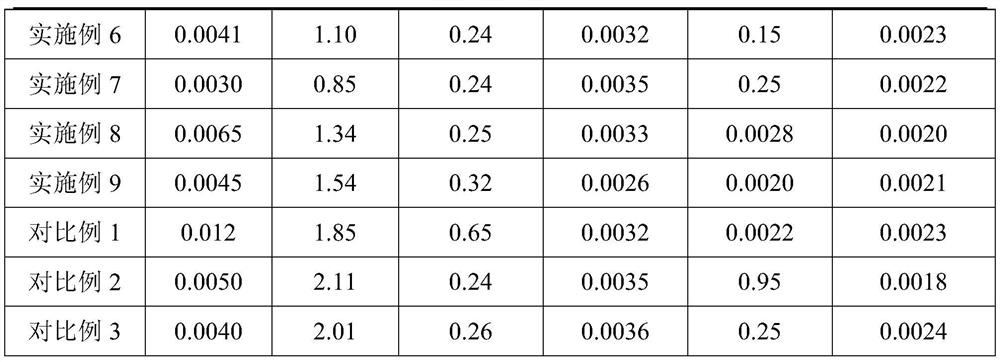

[0033]The mass percentage of non-oriented electrical steel components is: C≤0.010%, Si≤1.6%, Als≤0.80%, Mn≤0.50%, S≤0.0080%, N≤0.0080%, and the rest is iron and unavoidable impurities;

[0034] The production steps are as follows:

[0035] (1) Smelting process: After pretreatment and desulfurization, the molten iron enters the converter for steelmaking, then vacuum decarburization and alloying to obtain molten steel that meets the above composition and purity, and then casts;

[0036] (2) Continuous casting-hot rolling process: the molten steel enters the mold of the continuous casting machine through the tundish, and is poured into a cast slab through a fan-shaped section. After being scaled, it is rolled in a finishing mill and layer cooled to obtain non-oriented electrical steel hot-rolled raw materials with a thickness of 0.5-1.2mm (hot-rolled plate thickness); the cas...

experiment example

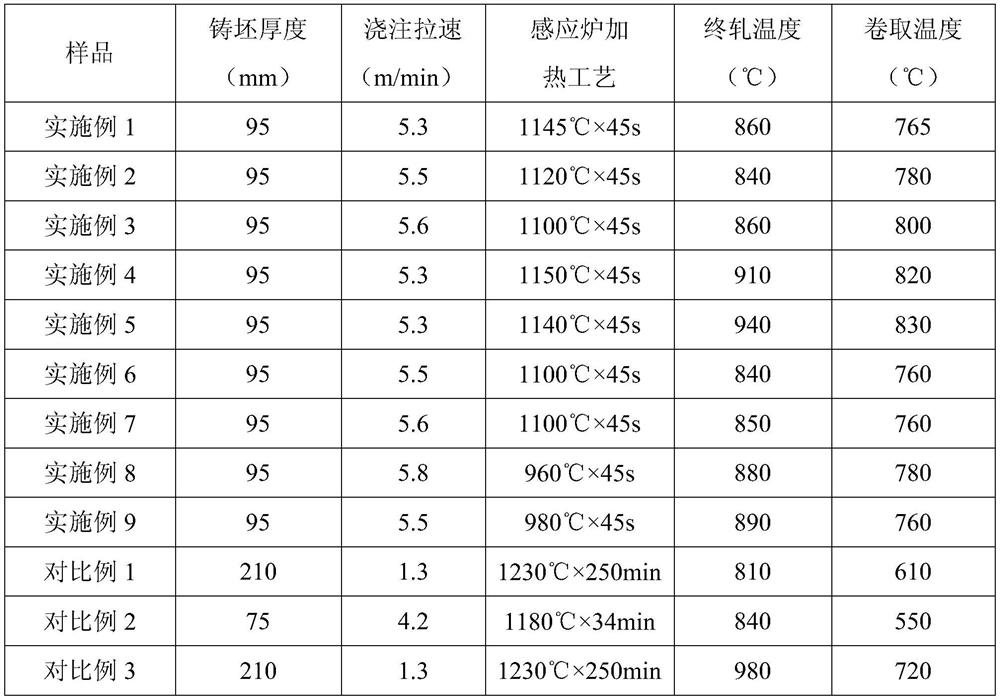

[0047] The thickness and magnetic property detection of the semi-process non-oriented electrical steel produced in Example 1-Example 9 and Comparative Example 1-Comparative Example 3 are shown in Table 3:

[0048] Table 3 Product thickness, critical reduction ratio and magnetic properties of each process

[0049]

[0050] The results show that the semi-process non-oriented electrical steel produced by the endless rolling of the present invention has excellent magnetic properties, reduces the production process, reduces the production cost, and realizes short process and high-efficiency manufacturing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com