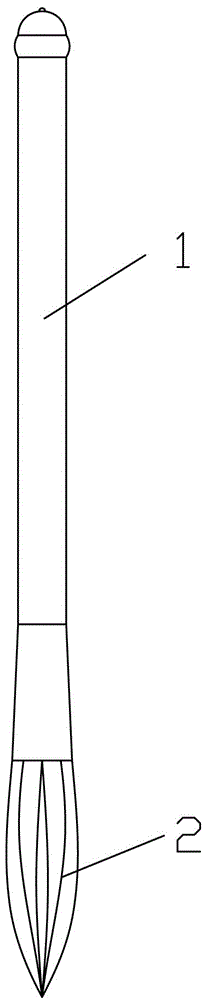

Writing brush and manufacturing method thereof

A production method and technology of writing brushes, applied to nibs, other ink pens, printing, etc., can solve the problems of high production cost, huge time, manpower, and slow production speed of Jianhao brushes, so as to alleviate the shortage of wool quantity and degreasing time Short, heavy-ink effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0029] Example 2, the weight percentage of the hemp wool is 10%, and the weight percentage of the wool is 90%.

[0030] The making method of writing brush, comprises the following steps:

[0031] a) Coarse degreasing; place the wool with the root down and the front up, and then use 160°C clarified lime water vapor to degrease the wool from bottom to top. The degreasing time is 0.6min; Immerse in the citric acid solution upwards for 1.0 min; the pH of the citric acid solution is 6.4, and the temperature is 51°C;

[0032] b) Fine degreasing; place the wool obtained in step a) with its roots facing upwards and its front facing downwards, and then use 140°C clarified lime water vapor to degrease the wool from bottom to top for 1.5 minutes; then take out the wool, Immerse in the citric acid solution for 2 minutes with the roots facing up and the front facing down; the pH of the citric acid solution is 6.6 and the temperature is 52°C;

[0033] c) Cleaning and degreasing; place the...

Embodiment 3

[0034] Example 3, the percentage by weight of the hemp wool is 13%, and the percentage by weight of the wool is 87%.

[0035] The making method of writing brush, comprises the following steps:

[0036] a) Coarse degreasing; place the wool with the root down and the front up, and then degrease the wool from bottom to top with clarified lime water vapor at 170°C for 0.4 minutes; then take out the wool and place the wool with the root down and the front Immerse in the citric acid solution upwards for 1.8 minutes; the pH of the citric acid solution is 6.4 and the temperature is 51°C;

[0037] b) Fine degreasing; place the wool obtained in step a) with its roots facing up and its front facing down, and then use 144°C clarified lime water vapor to degrease the wool from bottom to top for 1.3 minutes; then take out the wool, Immerse in the citric acid solution for 1.6 minutes with the roots facing up and the front facing down; the pH of the citric acid solution is 6.6 and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com