Bio-solid materials as alternate fuels in cement kiln, riser duct and calciner

a technology of biosolid materials and cement kilns, which is applied in the direction of biofuels, fuels, waste based fuels, etc., can solve the problem that the largest cost item in the manufacture of cement is the cost of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

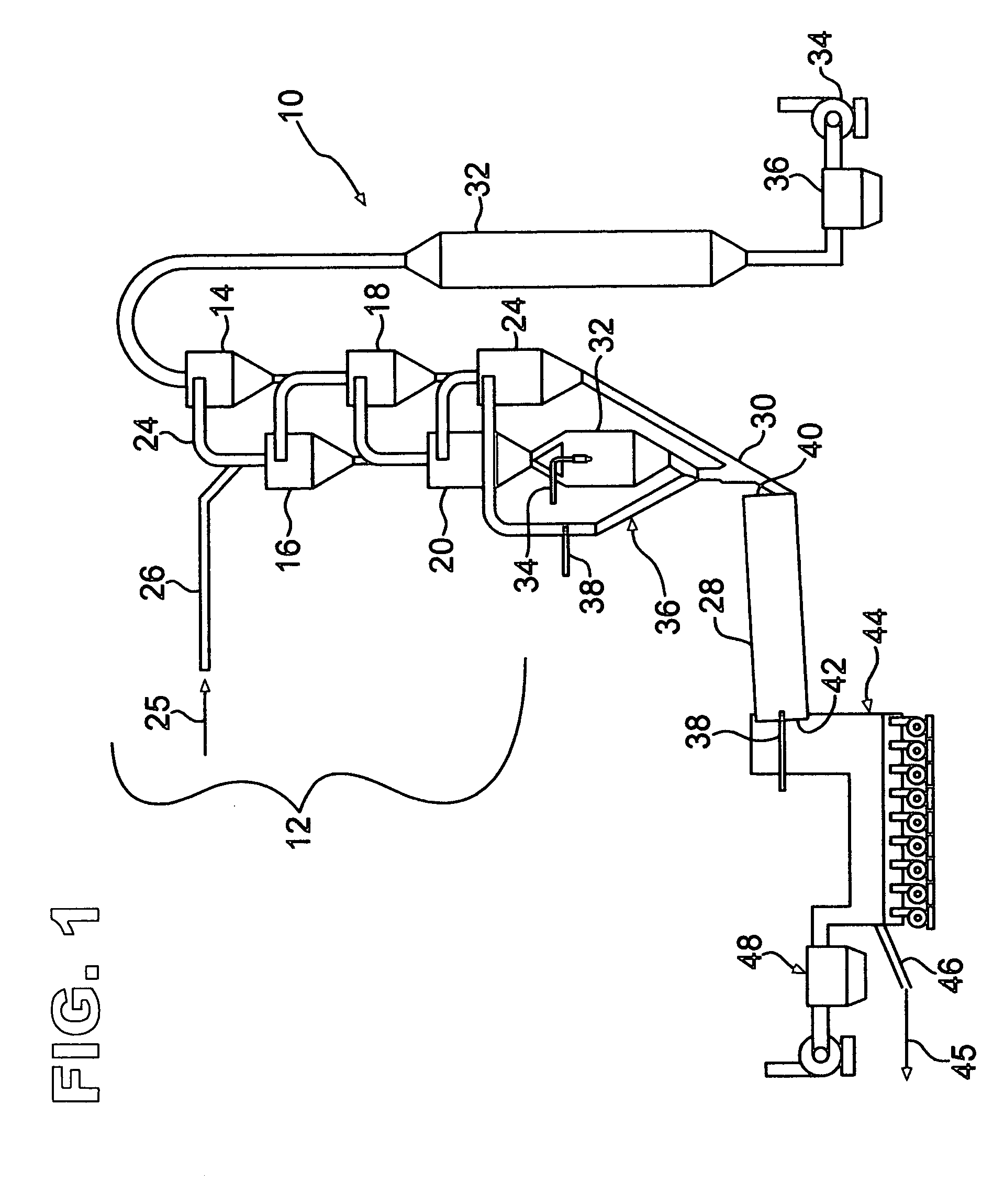

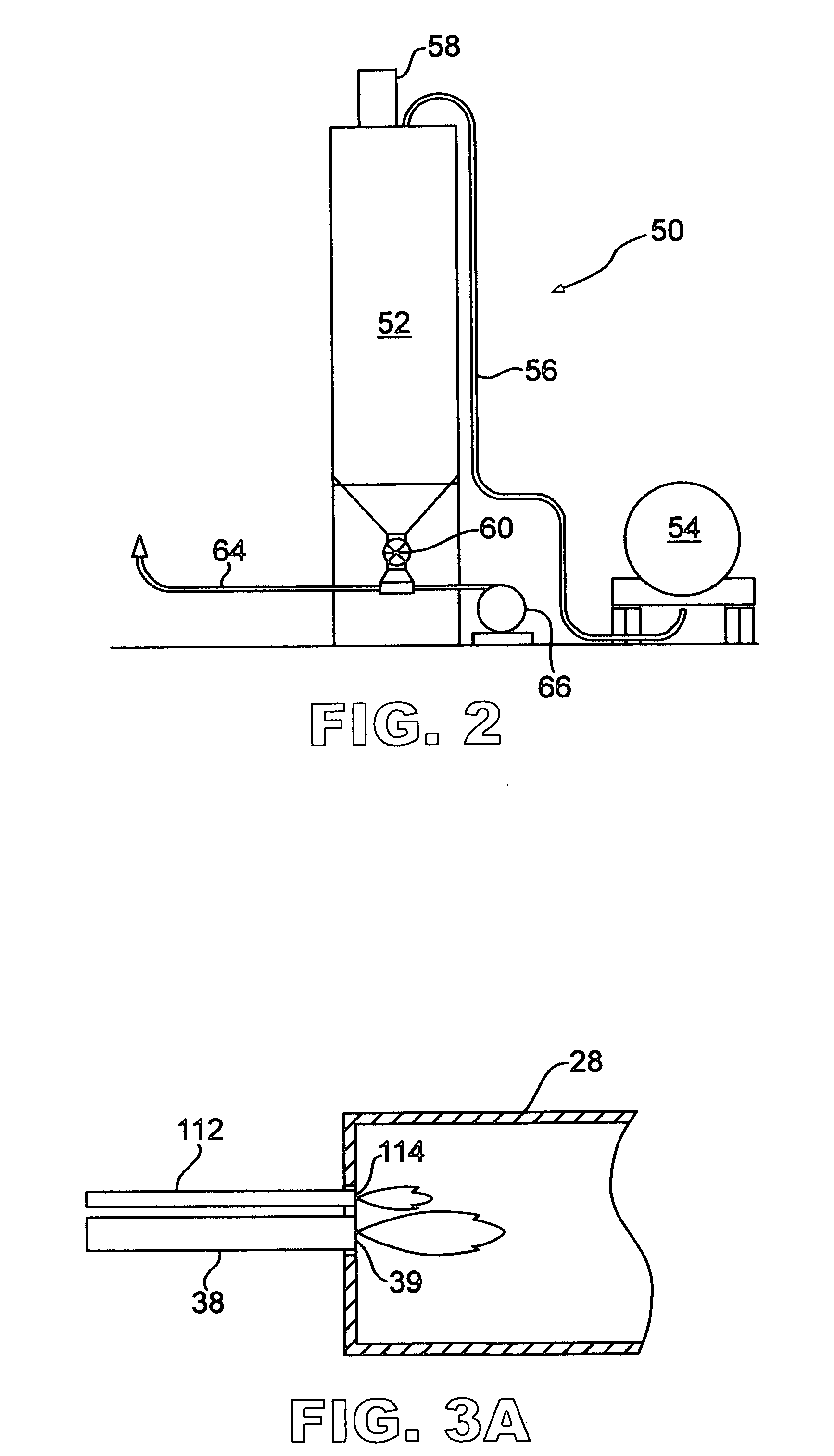

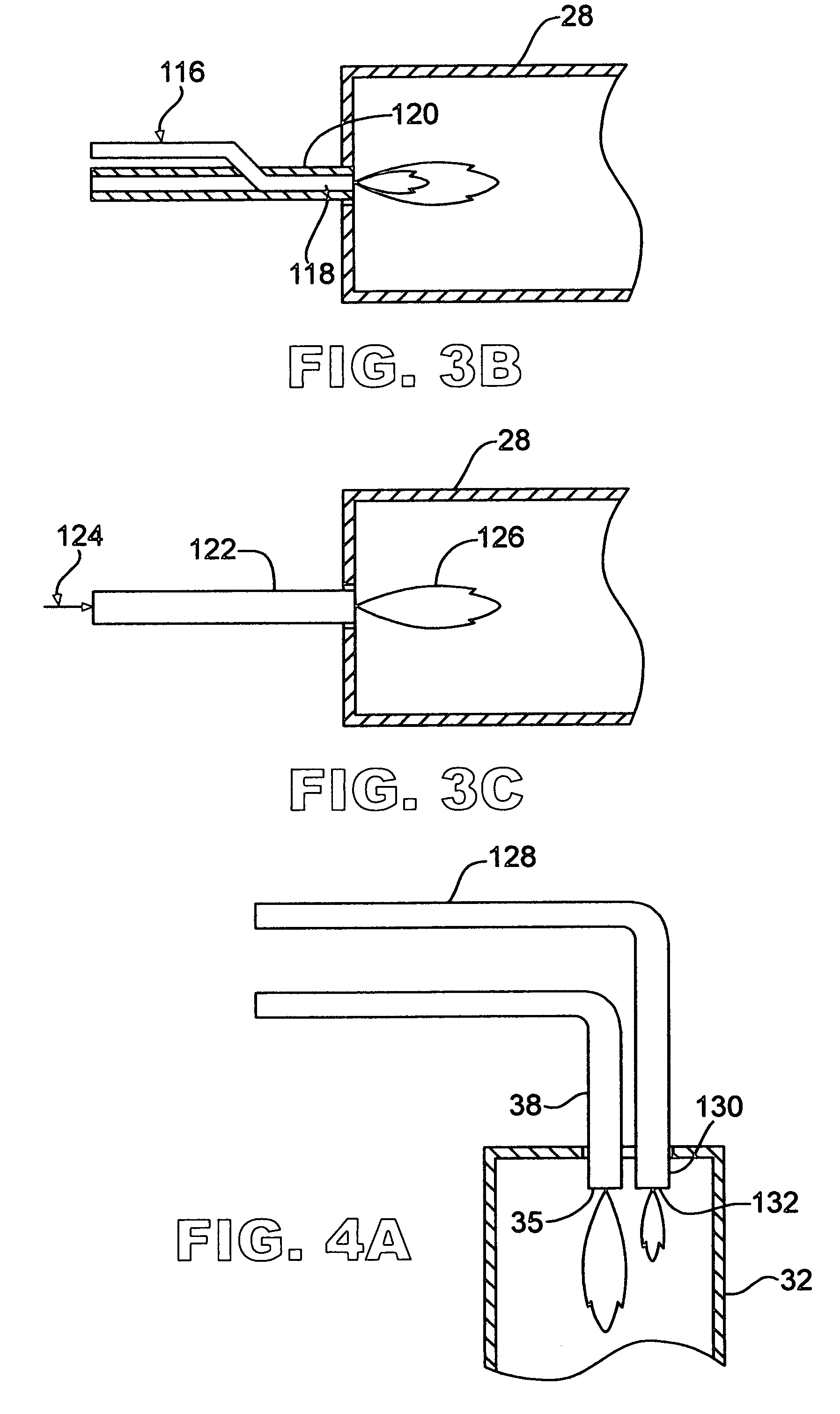

Image

Examples

Embodiment Construction

[0038] Waste materials are defined as residual by-products from municipal activities, farming or food processing, wood and paper processing and / or manufacture, and industrial processes.

[0039] Table 1 sets forth general categories of waste materials that would be usable in the method and apparatus of the present invention.

TABLE 1Fuel % / Ash %Critical AshMaterialSolid % / Liquid %(Dry)Fuel BTU's / lb (Dry)ComponentsMunicipal Waste85 / 1570 / 305,000-8,000P2O5, ClWood Waste80 / 2070 / 305,000-8,000Na2O, K2OIndustrial Waste80 / 2050 / 505,000-8,000variesFood Processing80 / 2050 / 505,000-8,000variesWasteAgricultural Waste80 / 2050 / 505,000-8,000varies

[0040] Example of Municipal waste are refuse derived fuel, waste water treatment sludge, grease, scum and screenings.

[0041] Examples of wood waste are bark, hardwoods, railroad ties, saw dust, softwoods, woodex pellets, board plant waste, planer shavings, sander dust, slash, urban wood waste, zinc borate and OSB waste.

[0042] Examples of Industrial waste are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com