Method for manufacturing position phase array machine capable of adjusting two-dimensional photon microstructure

A technology of photonic microstructure and manufacturing method, which is applied in the field of optical communication and optical multi-channel imaging, can solve the problems of difficult array light emission and difficult manufacturing process, etc., and achieve the effect of simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

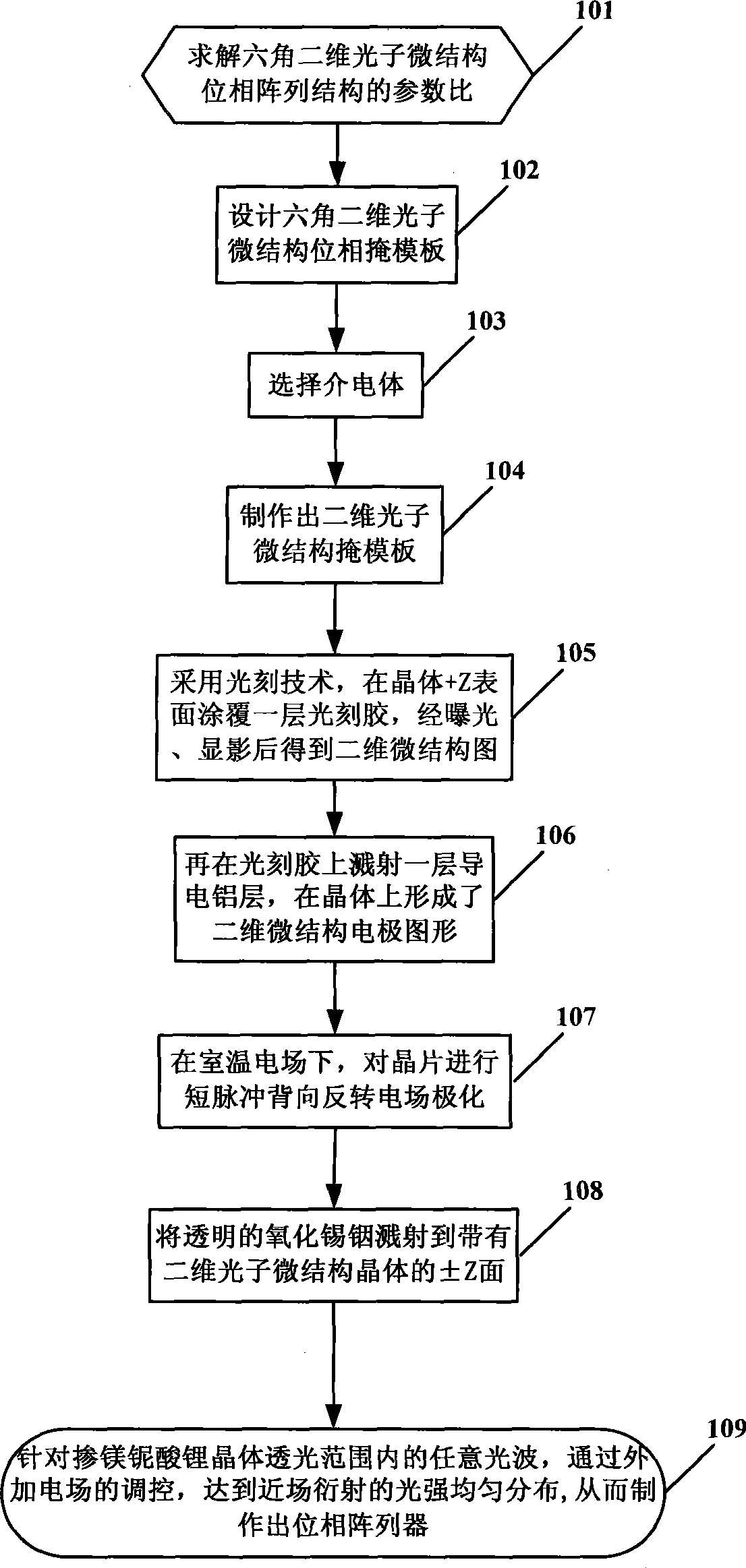

[0024] figure 1 It is a flowchart of a manufacturing method of an adjustable two-dimensional photonic microstructure phase array device. figure 1 In step 101, analyze and numerically simulate the complex amplitude distribution of the light wave and the complex amplitude distribution of the hexagonal two-dimensional photonic microstructure light array on the planes with different Talbot distances, and numerically solve the hexagonal two-dimensional photonic microstructure phase array structure theoretically. Parameter ratio dx / dy. According to the principle of light wave reversibility, if the phase array is made according to the periodic distribution of its phase, then under the illumination of light wave, an array im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com