Bulk silicon carbide aerogel material and preparation method thereof

A technology of silicon carbide and aerogel, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as limiting the application of materials, and achieve the effects of wide application range, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

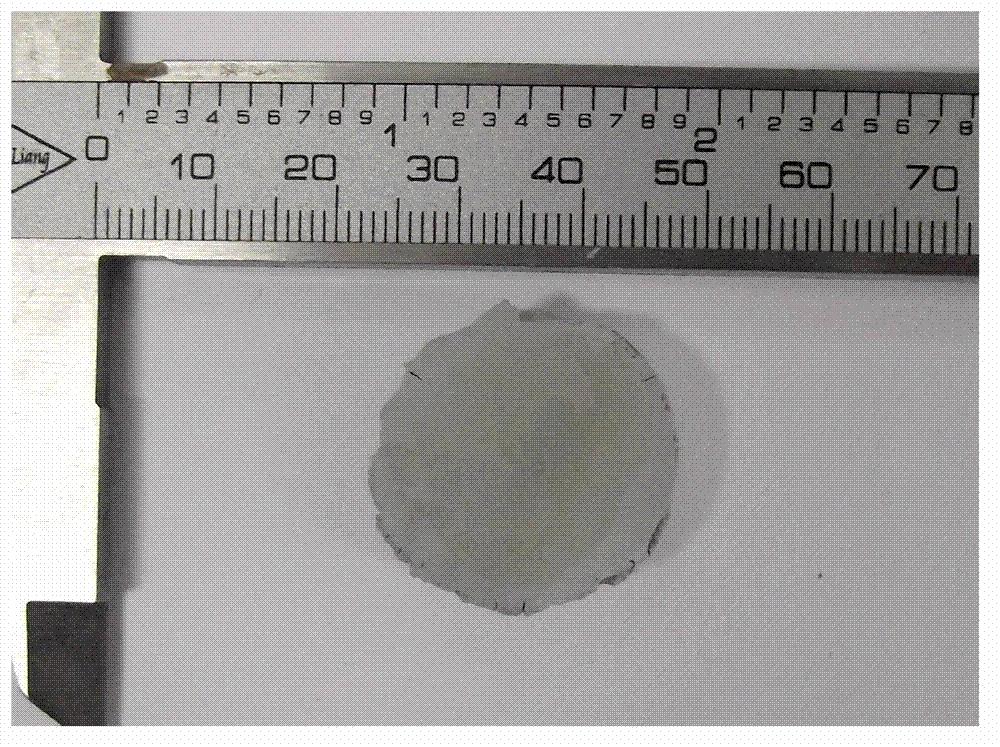

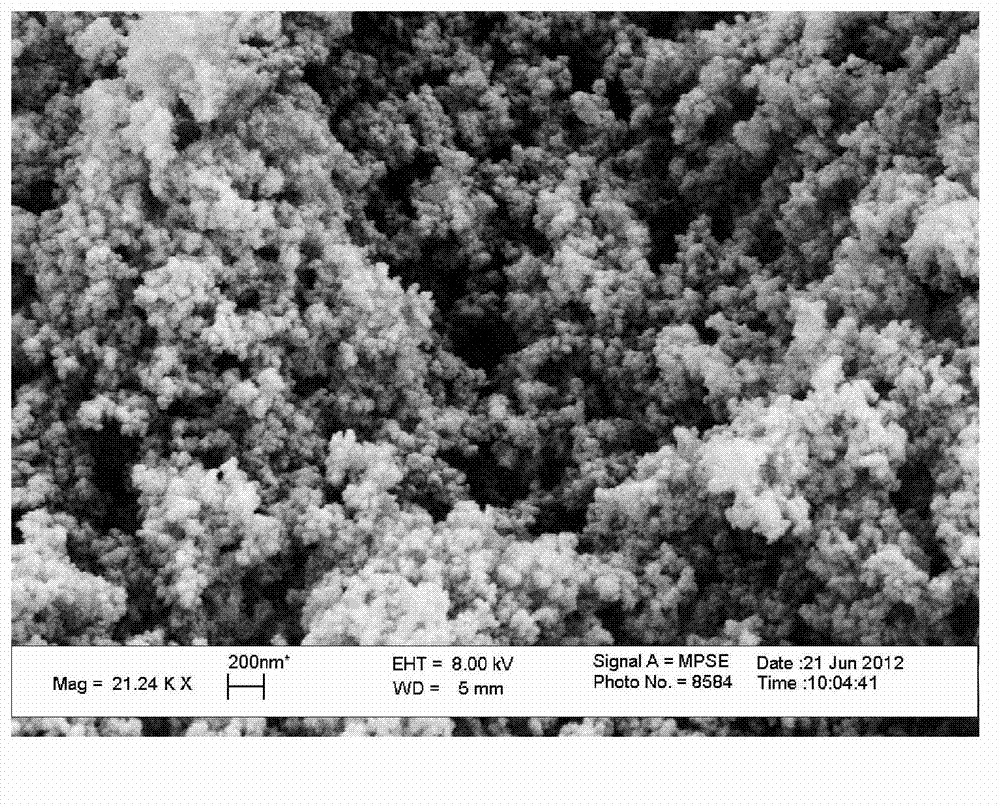

[0026] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:0.4:1.6:4:17, seal and place Carry out sol-gel reaction at room temperature of 20°C to obtain a wet gel. The wet gel is aged in an oven at 40°C for 24 hours. After taking out the wet gel, continue to dry it in an oven at 40°C for 24 hours to obtain a block RF -SiO 2 Composite airgel, the RF-SiO 2 The composite airgel was placed in a tube furnace, and the temperature was raised to 1500°C at a rate of 1°C / min under the protection of argon, and the temperature was lowered to 500°C after 10 hours of heat preservation, and then the argon was replaced by air , after 4 hours of heat preservation, it was cooled to room temperature to obtain a bulk silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.215g / cm 3 , BET specific surface area is 291m 2 / g, the pore size distribution is 10~70nm.

[0027] See attache...

example 2

[0031] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:2.4:0.6:6:14, seal and place Perform sol-gel reaction at room temperature at 25°C to obtain a wet gel. The wet gel is aged in an oven at 50°C for 18 hours. After taking out the wet gel, continue to dry it in an oven at 50°C under normal pressure for 18 hours to obtain a block RF -SiO 2 Composite airgel, the RF-SiO 2 The composite airgel is placed in a tube furnace, and the temperature is raised to 1550°C at a rate of 1°C / min under the protection of argon, and the temperature is lowered to 600°C after 10 hours of heat preservation, and then the argon is replaced by air , after 2 hours of heat preservation, it was cooled to room temperature to obtain a block silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.221g / cm 3 , BET specific surface area is 130m 2 / g, the pore size distribution is 30~100nm.

...

example 3

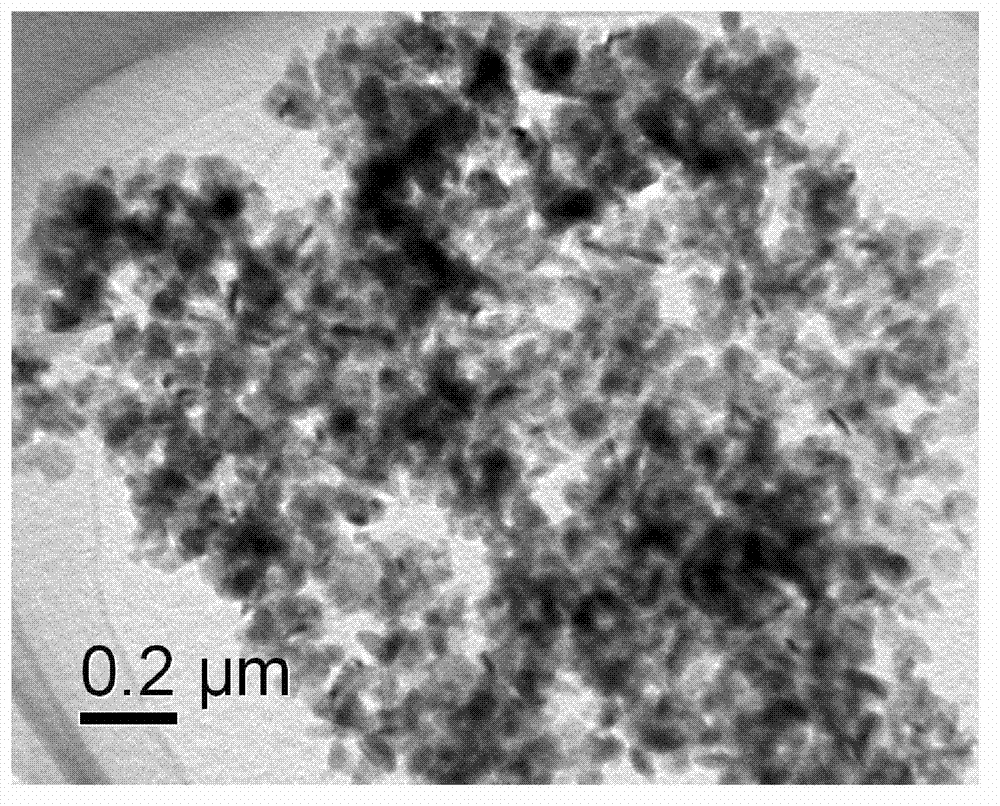

[0037] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:1.5:1.5:6:25, seal and place Perform sol-gel reaction at room temperature at 20°C to obtain a wet gel. The wet gel is aged in an oven at 60°C for 12 hours. After taking out the wet gel, continue to dry it in an oven at 60°C for 12 hours to obtain a block RF-SiO 2 Composite airgel, the RF-SiO 2 The composite airgel was placed in a tube furnace, and the temperature was raised to 1600°C at a rate of 1°C / min under the protection of argon. After 5 hours of heat preservation, the temperature was lowered to 600°C, and then the argon was replaced by air. , after 2 hours of heat preservation, it was cooled to room temperature to obtain a block silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.205g / cm 3 , BET specific surface area is 330m 2 / g, the pore size distribution is 10~100nm.

[0038] See attached pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com