Preparation method for ferrite nano-particles

A nanoparticle and ferrite technology, which is applied in the field of nanomaterial preparation and biomedical engineering applications, can solve the problems of poor dispersion and stability of nanoparticles, no successful method, size and shape changes, etc., and achieve good biophase Compatibility, improve biocompatibility, eliminate the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

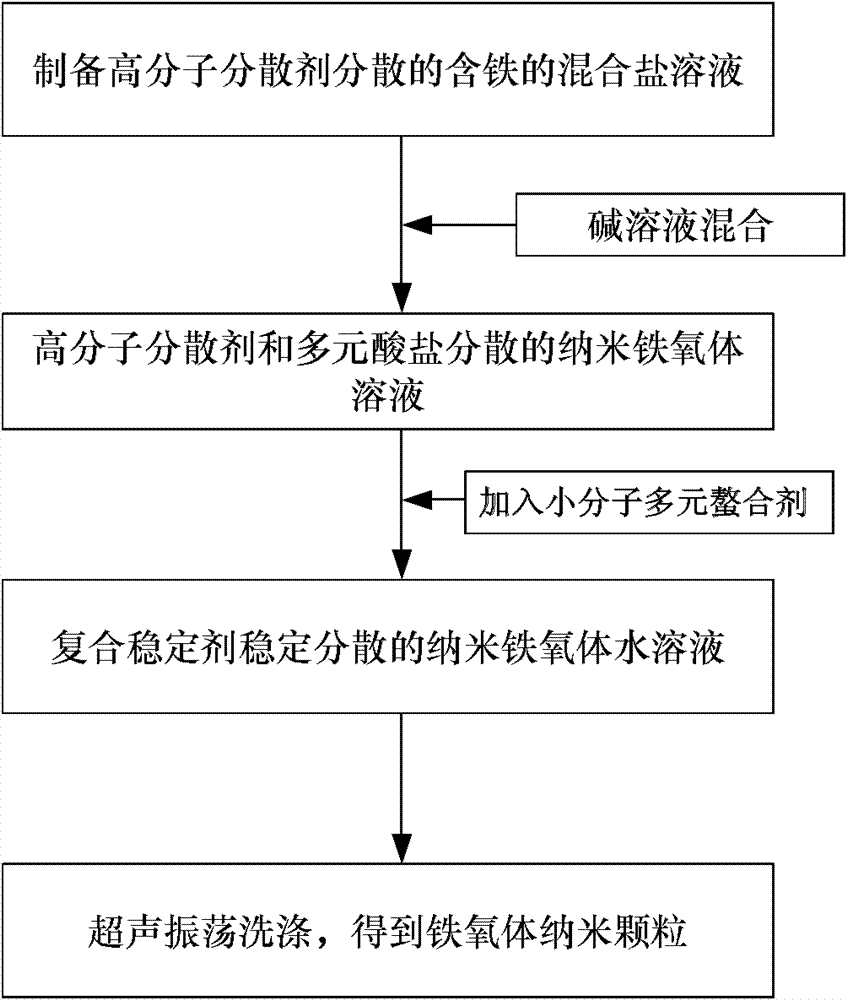

[0021] The present invention proposes a method for preparing ferrite nanoparticles, which is prepared by chemical co-precipitation, such as figure 1 As shown, it specifically includes the following steps:

[0022] Step 1: Add 0.01 to 10.0 g of polymer dispersant, 0.25 to 25 mmol (preferably 2.5 mmol) of FeCl 3 ·6H 2 O and 0.125 to 25 mmol (preferably 1.25 mmol) of FeCl 2 4H 2 O (the FeCl 2 4H 2 O can be replaced by the same amount of cobalt salts, manganese salts, nickel salts, zinc salts, gadolinium salts, europium salts or neodymium salts) dissolved in 300mL ultrapure water to obtain iron-containing mixed salts dispersed by polymer dispersants solution.

[0023] The polymer dispersant comprises one or two kinds of polyvinylpyrrolidone PVP, polyvinyl alcohol (PVA), polyacrylamide (PAM) and polyethylene glycol (PEG), polyacrylic acid (PPA), lignin Sodium Sulfonate, Ammonium Lignin Carboxylate. When it is a mixture of two polymer dispersants, there is no specific requir...

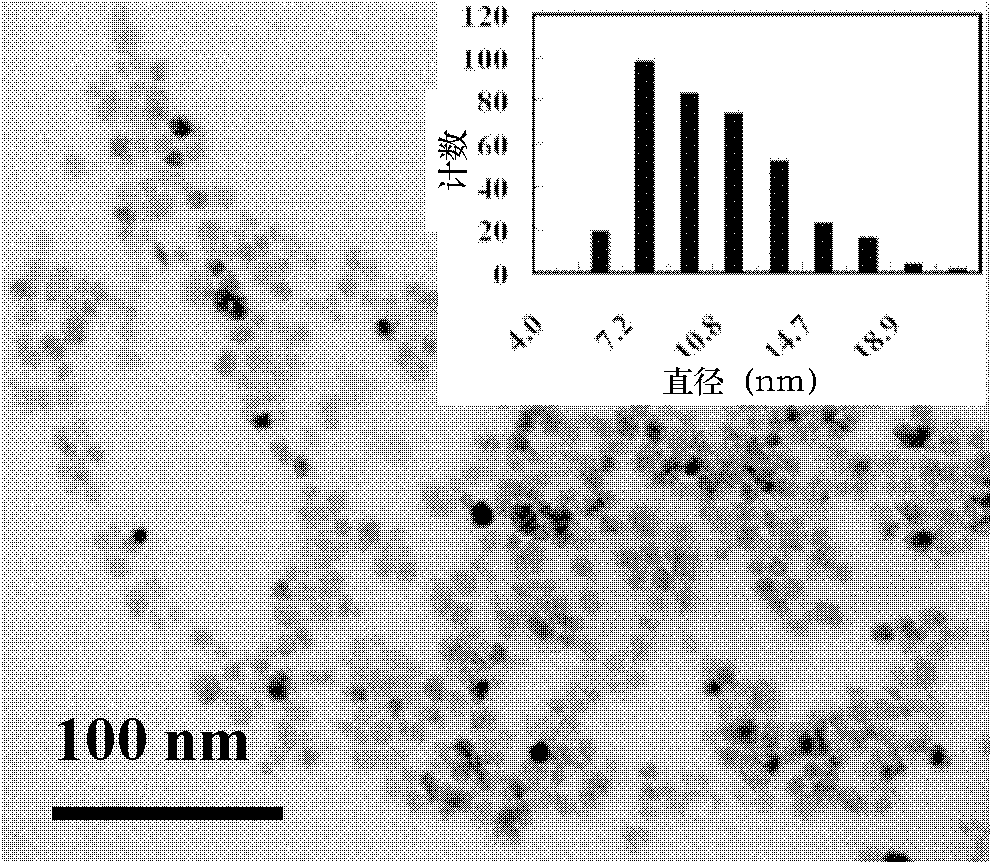

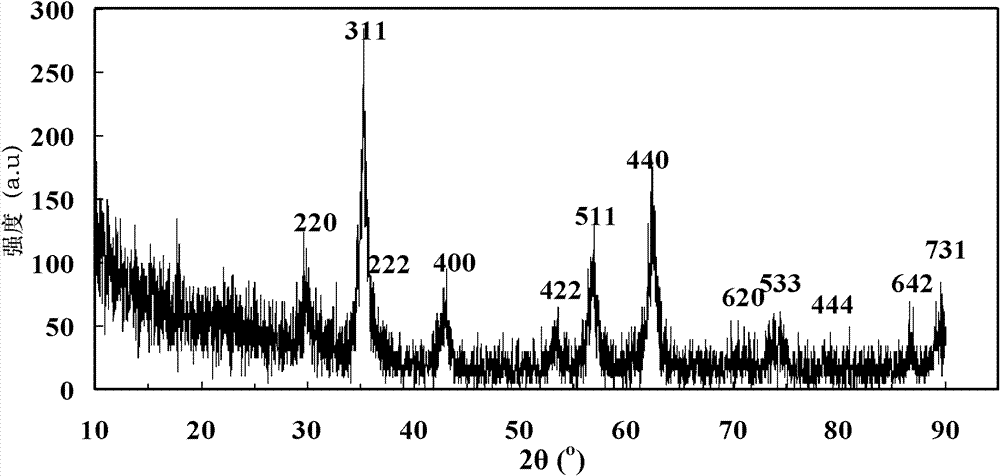

Embodiment 1

[0033] A method for preparing ferrite nanoparticles proposed in this embodiment specifically includes the following steps:

[0034] Step 1: 10.0g of polyvinylpyrrolidone (Mw=2000), 0.68g of 2.5mmol of FeCl 3 ·6H 2 O and 0.25g 1.25mmol of FeCl 2 4H 2 O was dissolved in 300mL ultrapure water to obtain an iron-containing mixed salt solution dispersed in a polymer dispersant.

[0035] Step 2: Dilute 58mL of NH with a pH equal to 10 4 The OH solution was added dropwise to the iron-containing mixed salt solution under ultrasonic vibration and nitrogen bubbling within 30 minutes to obtain a black-brown nano-ferrite solution dispersed in a polymer dispersant.

[0036] Step 3: Add 200mL of sodium citrate aqueous solution containing 34mmol of sodium citrate dropwise to the dark brown nano-ferrite solution dispersed in the polymer dispersant under the condition of ultrasonic oscillation and nitrogen bubbling within 10min to obtain the polymer dispersant Nano-ferrite solution dispers...

Embodiment 2

[0041] A method for preparing ferrite nanoparticles proposed in this embodiment specifically includes the following steps:

[0042] Step 1: 0.01g of polyvinylpyrrolidone (molecular weight is 100000), 0.68g of 2.5mmol of FeCl 3 ·6H 2 O and 0.25 g FeCl 2 4H 2 O was dissolved in 300mL ultrapure water to obtain an iron-containing mixed salt solution dispersed in a polymer dispersant.

[0043] Step 2: Add 30 mL of NaOH solution with a pH value equal to 10 to the iron-containing mixed salt solution under ultrasonic vibration and nitrogen bubbling within 30 minutes to obtain a black-brown nano-iron oxide dispersed in a polymer dispersant mixed with an alkali solution body solution.

[0044] Step 3: Add 200mL of sodium citrate aqueous solution containing 1.7mmol of sodium citrate dropwise to the dark brown nano-ferrite solution dispersed in polymer dispersant under the conditions of ultrasonic vibration and nitrogen bubbling within 30min to obtain polymer dispersion agent and pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com