Semiconductor Wafer Handling Equipment

A semiconductor and wafer technology, applied in the field of semiconductor wafer conveying equipment, can solve the problems of poor energy efficiency, excess cost, defects, etc., and achieve the effects of preventing power consumption, reducing work burden, and suppressing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] An object of the present invention is to provide a semiconductor wafer transfer tool capable of uniformly heating the surface of the wafer when heating the semiconductor wafer.

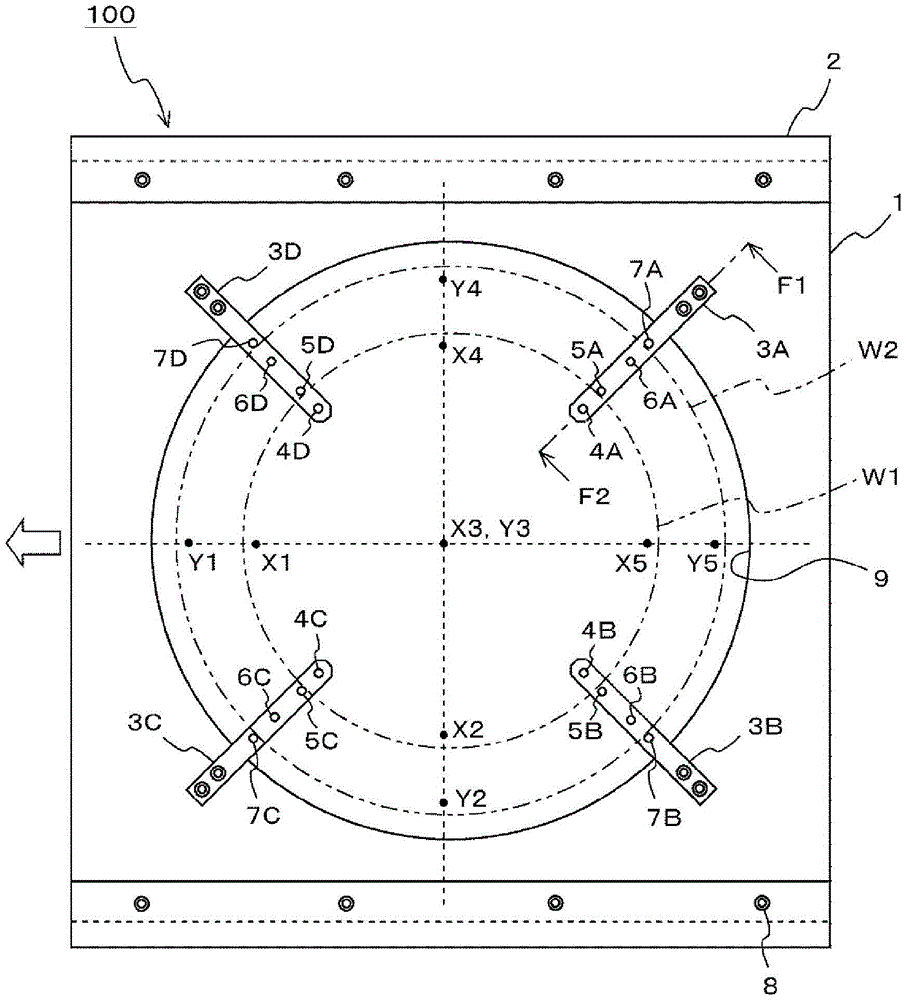

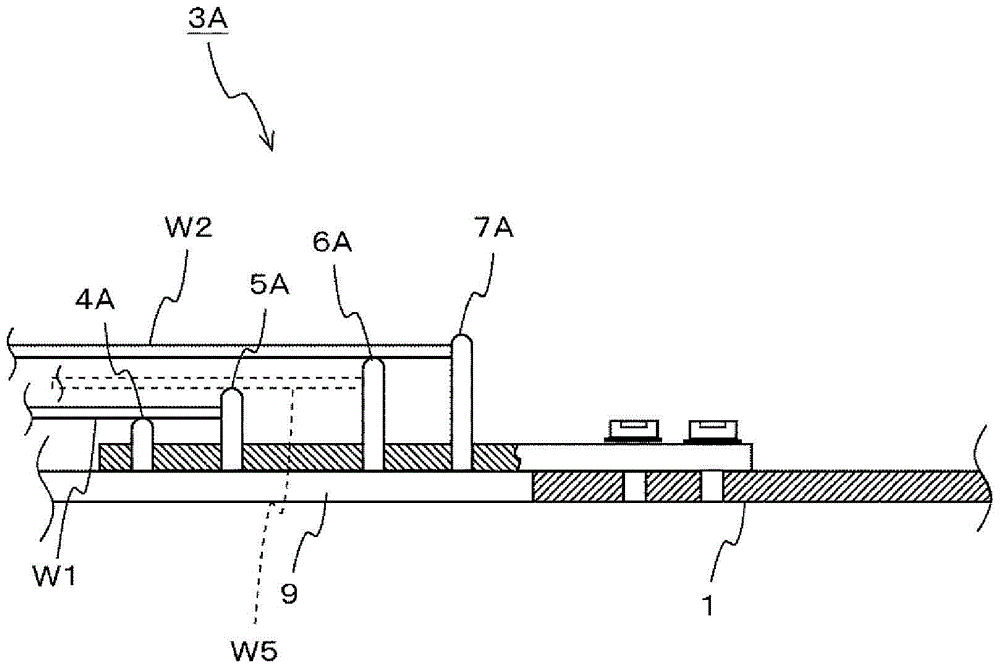

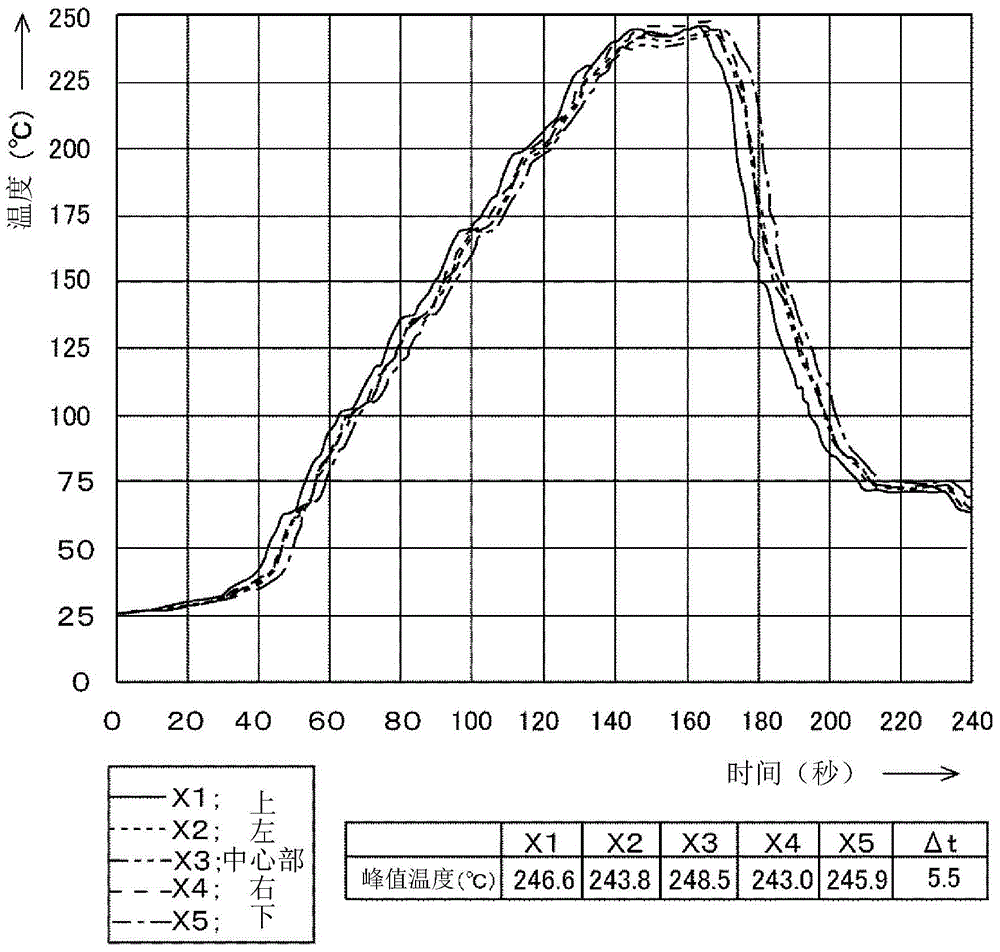

[0031] Next, embodiments of the present invention will be described with reference to the drawings. figure 1 is a plan view of an embodiment of the semiconductor wafer transfer tool of the present invention, figure 2 Shows examples of shapes of holding pins and wafer misalignment prevention guides (hereinafter simply referred to as prevention guides), figure 1 The enlarged view of the F1-F2 direction of the section.

[0032] That is, the wafer transport tool 100 of the embodiment constitutes an example of a semiconductor wafer transport tool, and is a tool for holding and transporting a semiconductor wafer in a semiconductor manufacturing process. There is an opening 9 at the center of the bottom plate 1 serving as an example of the main body, and conveying guides 2 are attached to the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com