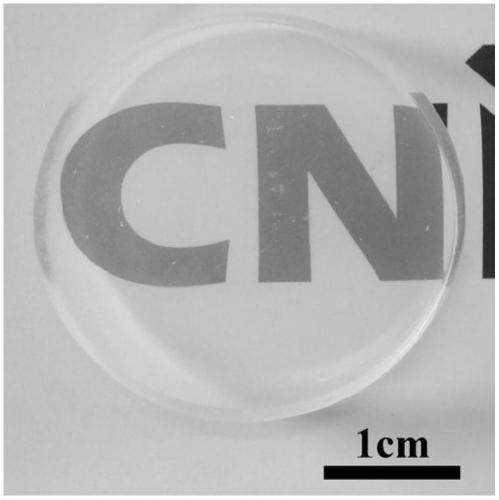

A kind of atmospheric pressure preparation method of transparent silica block airgel

A technology of silica and gel, applied in the field of normal pressure preparation of transparent silica block aerogel, can solve problems such as shortening the production cycle, and achieve the effect of excellent physical and structural properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

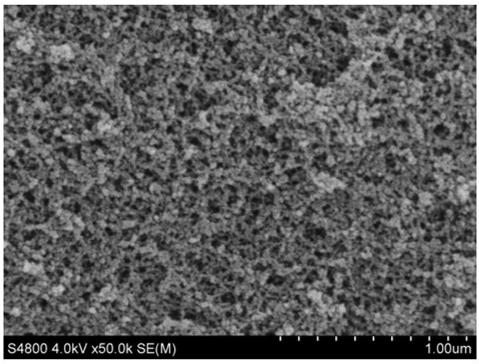

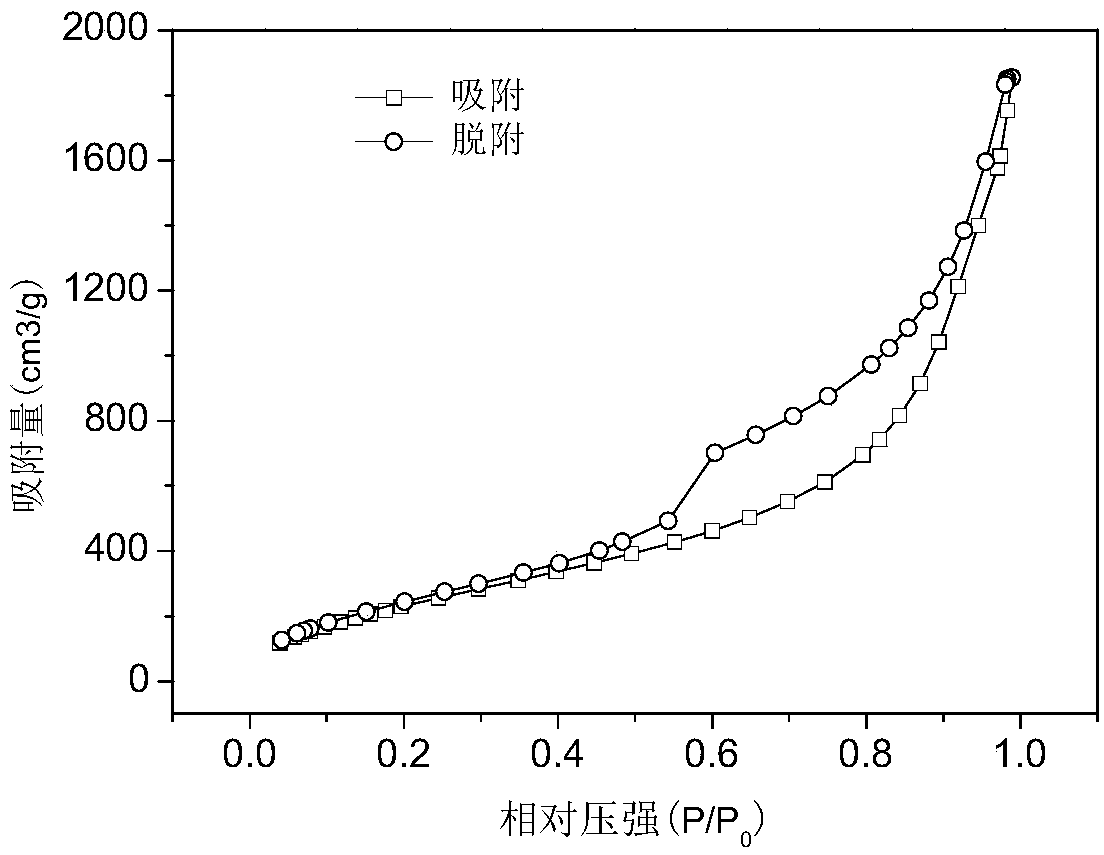

Embodiment 1

[0041] At 50°C, mix and stir ethyl orthosilicate, ethanol, and deionized water in a molar ratio of 1:6:3, add hydrochloric acid to adjust the pH to 3, and stir for 30 minutes; add ammonia water to the obtained sol to adjust the pH to 6.5 , after stirring evenly, stand still and seal to obtain a wet gel, add absolute ethanol and age in a water bath at 50°C for 12 hours to obtain an alcohol gel. Add a surface modification solution mixed with trimethylchlorosilane, n-hexane, and ethanol in a water bath at 50°C. The concentration of the silane coupling agent is 0.6 mol / L for 6 hours of initial modification, and continue to add 0.8 mol / L L surface modification solution for 8 hours of modification, at this time the light blue transparent gel is separated from the mold and suspended in the surface modification solution; continue to add 1mol / L surface modification solution for the third modification modification, modification time 8 Hours, during which the gel turns from transparent t...

Embodiment 2

[0044] At room temperature, mix and stir ethyl orthosilicate, ethanol, and deionized water according to the molar ratio of 1:10:5, add hydrochloric acid to adjust the pH to 2, and stir for 60 minutes; add ammonia water to the obtained sol to adjust the pH to 7, After stirring evenly, leave it to stand and seal to obtain a wet gel, add absolute ethanol and age at room temperature for 3 days to obtain an alcohol gel. Add trimethylchlorosilane / n-hexane / ethanol mixed surface modification solution in a water bath at 50°C. The concentration of the modification agent is 0.8mol / L for 8 hours of initial modification. At this time, the wet gel is still transparent; remove Reaction by-products, continue to add 0.8mol / L surface modification solution, carry out the second modification for 8 hours, the wet gel will gradually turn white from transparent, remove reaction by-products, continue to add 1.5mol / L surface modification solution , carry out the third to fifth hydrophobic modification...

Embodiment 3

[0047] At room temperature, mix and stir ethyl orthosilicate, ethanol, and water according to the molar ratio of 1:10:5, add hydrochloric acid dropwise to adjust the pH to 2, and stir for 60 minutes; add ammonia water to adjust the pH to 7, stir well, and let stand Seal it to obtain a wet gel, add absolute ethanol and age at room temperature for 3 days to obtain an alcohol gel. At room temperature, add trimethylchlorosilane / n-hexane / ethanol mixed surface modification solution to the alcohol gel, the concentration of the modification agent is 0.5mol / L, and carry out the initial hydrophobic modification for 12 hours, until the light blue transparent gel detaches The mold floats in the surface modification solution, and the gel is still transparent at this time; pour off the surface modification solution, then add 1mol / L surface modification solution, carry out the second hydrophobic modification for 8 hours, pour off the surface modification solution, and add 1.5 mol / L surface m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com