Bulk silicon carbide aerogel material and preparation method thereof

A technology of airgel and silicon carbide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as limiting the application of materials, achieve a wide range of applications, reduce production costs, increase operability and controllability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

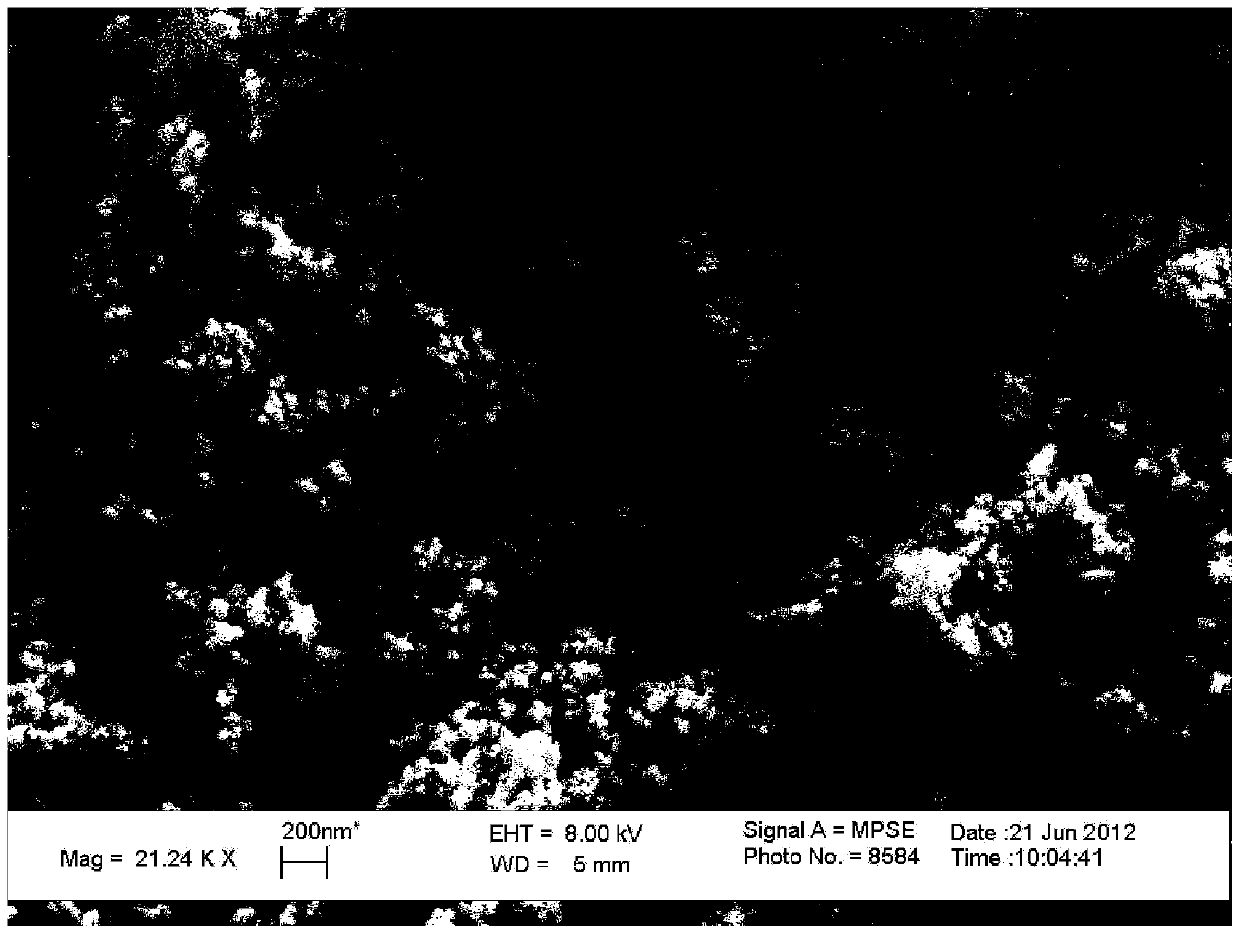

[0026] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:0.4:1.6:4:17, seal and place Carry out sol-gel reaction at room temperature of 20°C to obtain a wet gel. The wet gel is aged in an oven at 40°C for 24 hours. After taking out the wet gel, continue to dry it in an oven at 40°C for 24 hours to obtain a block RF -SiO 2 Composite airgel, the RF-SiO 2 The composite airgel was placed in a tube furnace, and the temperature was raised to 1500°C at a rate of 1°C / min under the protection of argon, and the temperature was lowered to 500°C after 10 hours of heat preservation, and then the argon was replaced by air , after 4 hours of heat preservation, it was cooled to room temperature to obtain a bulk silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.215g / cm 3 , BET specific surface area is 291m 2 / g, the pore size distribution is 10~70nm.

[0027] See attache...

example 2

[0031] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:2.4:0.6:6:14, seal and place Perform sol-gel reaction at room temperature at 25°C to obtain a wet gel. The wet gel is aged in an oven at 50°C for 18 hours. After taking out the wet gel, continue to dry it in an oven at 50°C under normal pressure for 18 hours to obtain a block RF -SiO 2 Composite airgel, the RF-SiO 2 The composite airgel is placed in a tube furnace, and the temperature is raised to 1550°C at a rate of 1°C / min under the protection of argon, and the temperature is lowered to 600°C after 10 hours of heat preservation, and then the argon is replaced by air , after 2 hours of heat preservation, it was cooled to room temperature to obtain a block silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.221g / cm 3 , BET specific surface area is 130m 2 / g, the pore size distribution is 30~100nm.

...

example 3

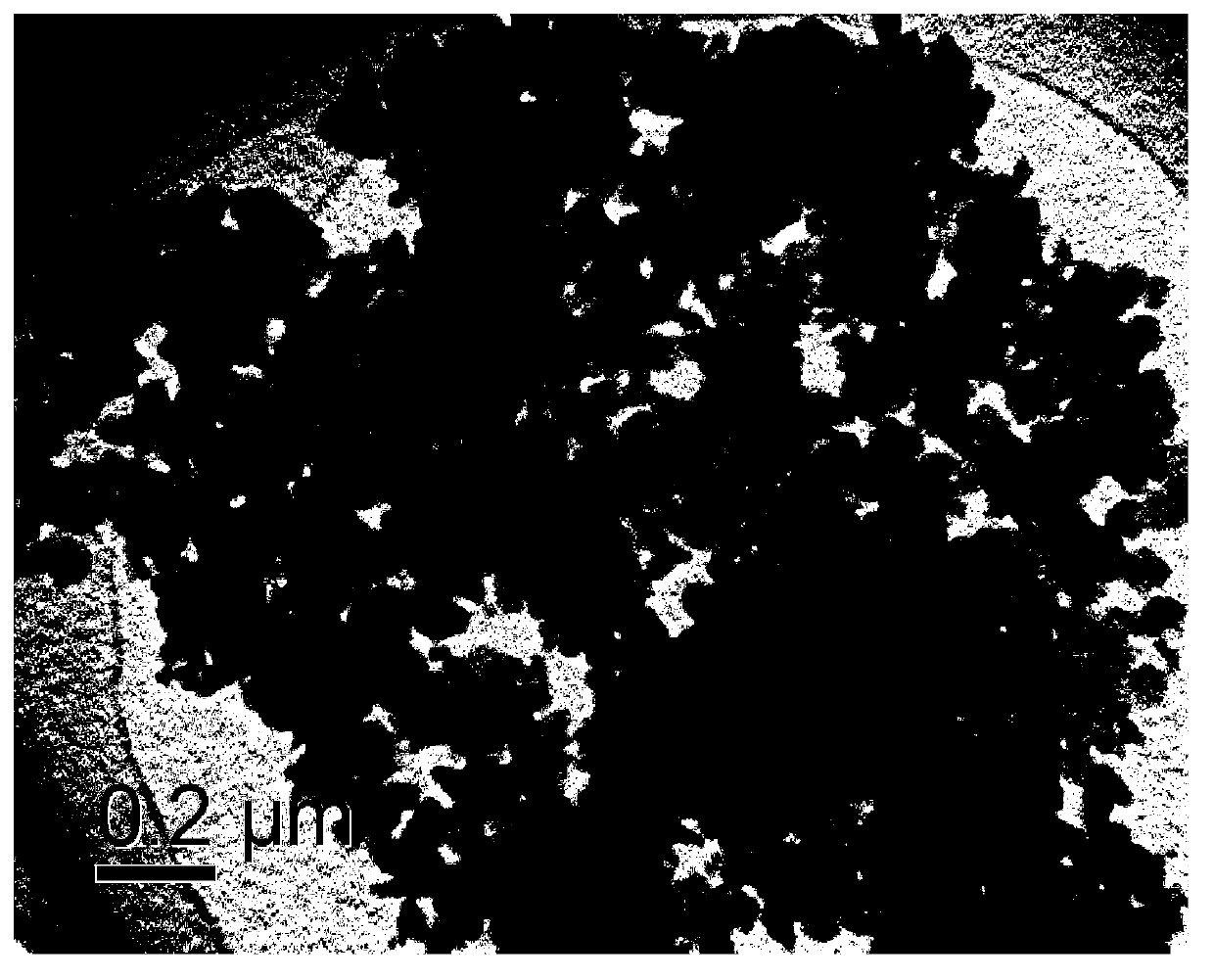

[0037] Mix catechol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:1.5:1.5:6:25, seal and place Perform sol-gel reaction at room temperature at 20°C to obtain a wet gel. The wet gel is aged in an oven at 60°C for 12 hours. After taking out the wet gel, continue to dry it in an oven at 60°C for 12 hours to obtain a block RF-SiO 2 Composite airgel, the RF-SiO 2 The composite airgel was placed in a tube furnace, and the temperature was raised to 1600°C at a rate of 1°C / min under the protection of argon. After 5 hours of heat preservation, the temperature was lowered to 600°C, and then the argon was replaced by air. , after 2 hours of heat preservation, it was cooled to room temperature to obtain a block silicon carbide airgel material. The apparent density of silicon carbide airgel material is 0.205g / cm 3 , BET specific surface area is 330m 2 / g, the pore size distribution is 10~100nm.

[0038] See attached pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com