Refining degumming method for silk fiber and its fabrics

A technology of silk fiber and degumming method, which is applied in the field of degumming of silk fiber and its fabric, can solve the problems of long processing time, large consumption of chemicals, waste of water resources, etc., to achieve clean production and reduce pollutants Effects of emissions and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

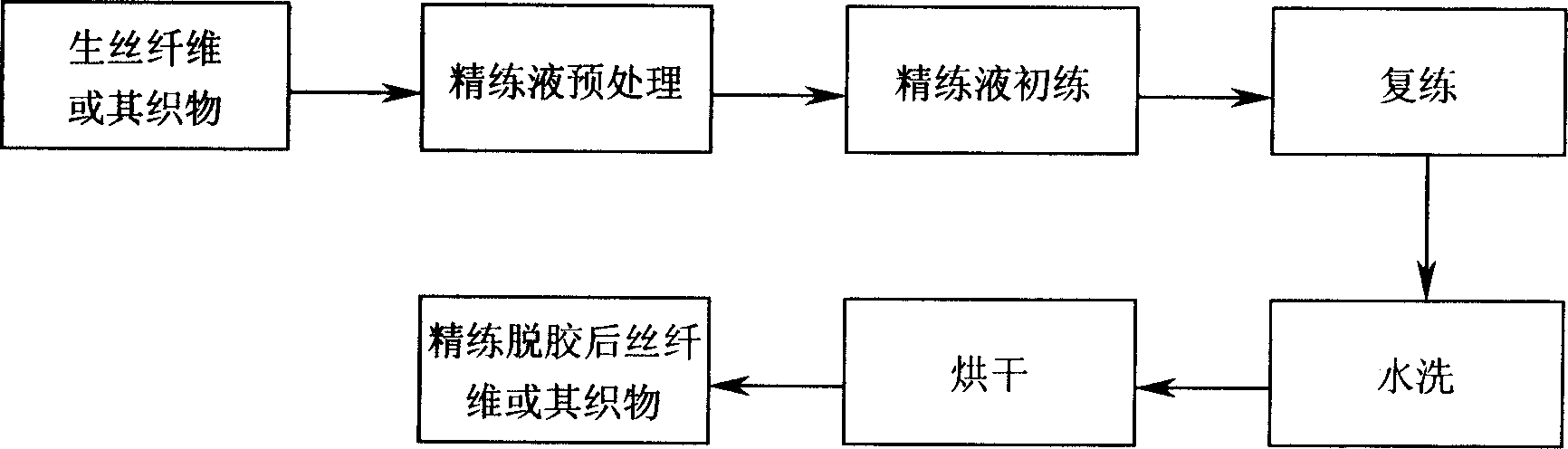

Method used

Image

Examples

Embodiment 1

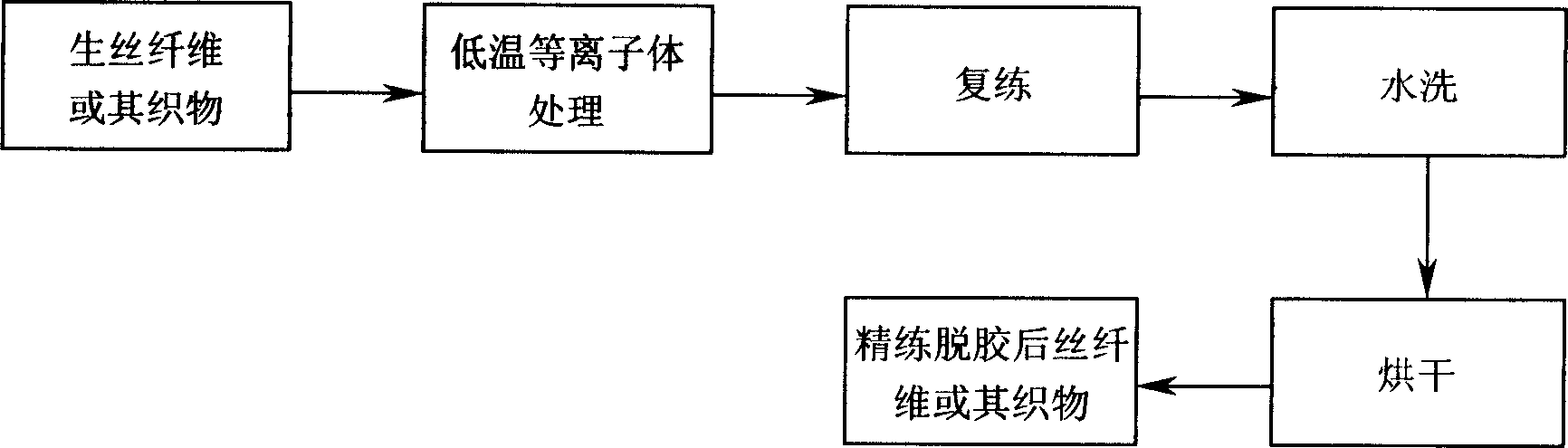

[0018] See attached figure 2 , the technical process of silk fabric scouring and degumming in this embodiment is as follows figure 2 shown.

[0019] The fabric to be scoured and degummed is made of silk power spinning green body, unit weight: 90.64g / m 2 ;Dry the raw silk sample in an electric blast drying oven at a temperature of 110°C to constant weight, then put the sample into a low-temperature plasma processor preheated for 30 minutes, and use intermittent low-temperature plasma processing Method, the working atmosphere is argon, start to fill in argon with a vacuum of 5Pa, when the pressure reaches 80Pa, treat it with a discharge power of 60W for 5min; after taking it out, use a refining agent (formula: Na 2 CO 3 1.0g / L, Na 2 SiO 3 1.0g / L, sodium hydrosulfite 0.5g / L, dispersant 2.0g / L), according to the re-training process (bath ratio 1:50, temperature 98 ° C, time 40min) directly for re-training; then fully washed (95 ℃, 60 ℃ hot water and cold water fully washe...

Embodiment 2

[0035] Present embodiment is to the technological process of silk fabric refining degumming as figure 2 shown. The fabric used is silk twill, unit weight: 72g / m 2 ;Dry the raw silk sample in an electric blast drying oven with a temperature of 110°C to constant weight, then put the sample into a low-temperature plasma processor preheated for 30 minutes, adopt a continuous processing method, argon As the working gas of the low-temperature plasma, argon gas is filled with a background vacuum degree of 6Pa, and when the pressure reaches 20Pa, it is treated with a discharge power of 50W for 5 minutes; then, the retraining process formula and conditions of Example 1 are followed directly for retraining. Practice; then fully wash and dry.

[0036] Carry out dyeing processing to the fabric after the above-mentioned refining and degumming process, dyeing prescription:

[0037] Weak acid pink B4% (o.w.f), Yuanming powder 1 (g / l), Pingpingjia O 0.1 (g / l), bath ratio 1:100.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com