Preparation method for flexible and highly-conductive composite carbon fiber cloth

A composite carbon fiber, high conductivity technology, applied in fiber processing, plant fibers, circuits, etc., can solve the problems of unfavorable large-scale production and application, limit the application of carbonized cotton cloth, and small effective interface, and achieve good interface bonding force and good flexibility , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

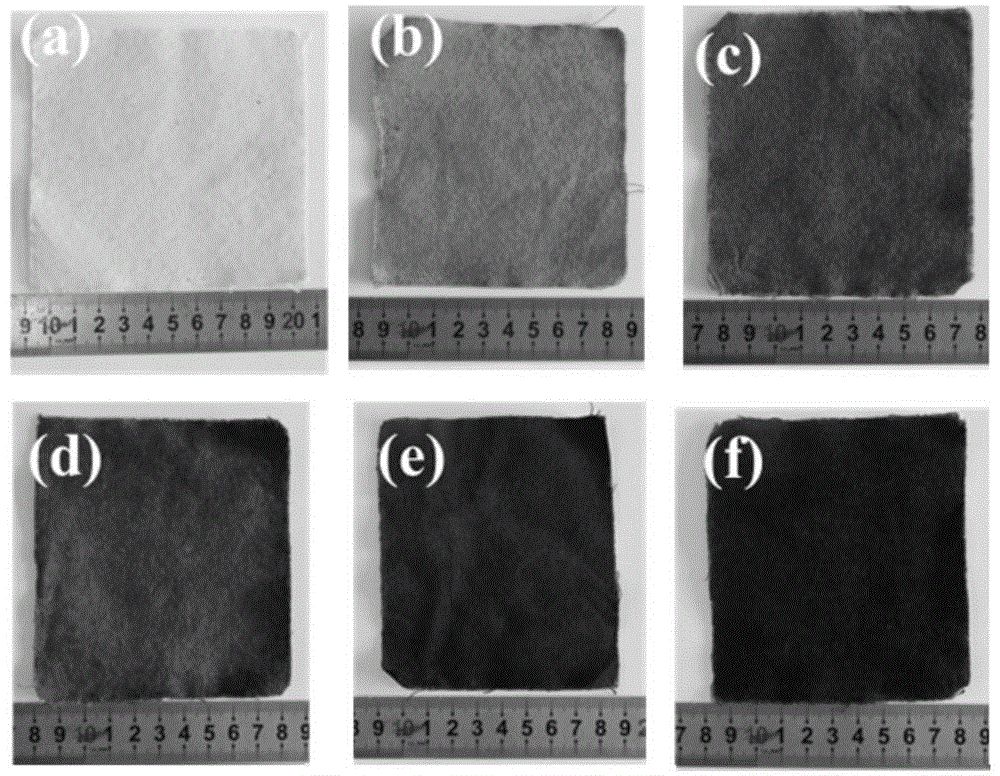

[0053] Take the above seven pieces of cotton cloth, impregnate and compound carbon nanotubes of different qualities, respectively (a) 0mg, (b) 3.3mg, (c) 6.1mg, (d) 15.8mg, (e) 33.3mg, (f) 75mg, and then the composite cotton precursor was dried in an oven at 70°C for 12h, corresponding to figure 1 (a), (b), (c), (d), (e) and (f), take it out and put it in a tube furnace, vacuumize, use argon as protective gas (flow rate is 1000sccm), and heat at 10°C The temperature was raised to 1000°C at a rate of 1 / min, heat-treated under argon for 2 hours, and then lowered to room temperature under the protection of argon. The obtained samples were as follows: Figure 4 shown. The contents of carbon nanotubes in the six samples are: 0, 1wt%, 2wt%, 5wt%, 10wt%, and 20wt%; Figure 7 shows that pure carbon fiber cloth, Figure 8 Scanning electron micrographs in , show that the cotton cloth is woven from regular cotton threads, and the surface of the carbon fibers is uniformly coated with c...

Embodiment 2

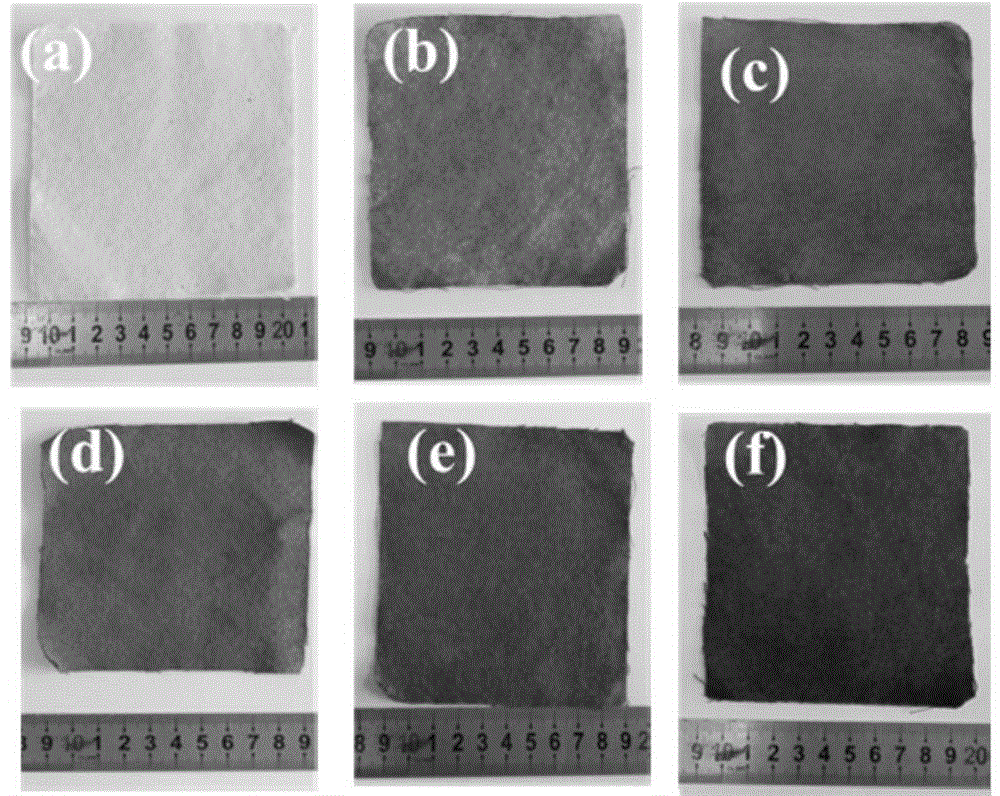

[0055] Take the above seven pieces of cotton cloth, impregnate and compound graphene of different quality, respectively (a) 0mg, (b) 3.3mg, (c) 6.1mg, (d) 15.8mg, (e) 33.3mg, (f) 75mg , and then put the composite cotton precursor in an oven at 70°C for 12 hours, corresponding to figure 2 (a), (b), (c), (d), (e) and (f), take it out and put it in a tube furnace, vacuumize, use argon as protective gas (flow rate is 1000sccm), and heat at 10°C The temperature is raised to 1000°C at a rate of 1 / min, the heat treatment time is 2h under argon, and the temperature is lowered to room temperature under the protection of argon. (Such as Figure 5 Shown) the graphene contents in the six samples are respectively: 0, 1wt%, 2wt%, 5wt%, 10wt%, and 20wt%. Figure 8 The scanning electron micrographs in the paper show that the cotton cloth is woven from regular cotton threads, and the carbon fiber surface is uniformly coated with graphene.

Embodiment 3

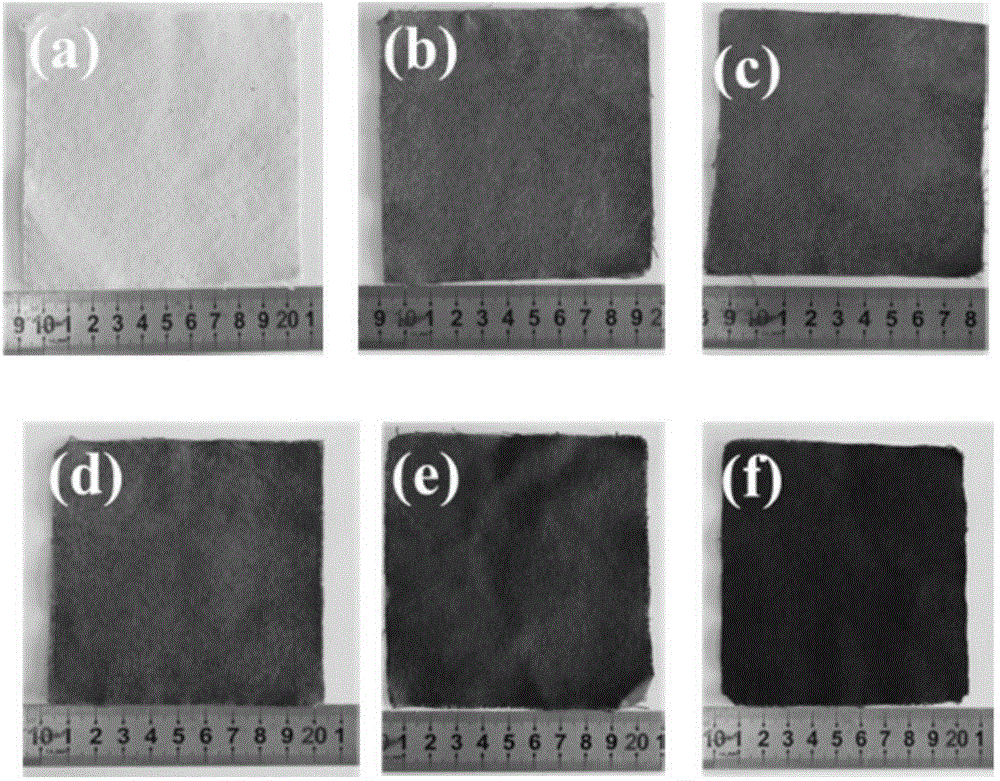

[0057] Take seven pieces of the above-mentioned cotton cloth, respectively impregnate the composite amount of carbon nanotubes and graphene mixed solution (mass ratio 1:1), followed by (a) 0mg, (b) 3.3mg, (c) 6.1mg, (d) 15.8mg, (e) 33.3mg, (f) 75mg, and then the composite cotton precursor was dried in an oven at 70°C for 12h, corresponding to image 3 (a), (b), (c), (d), (e) (f), take it out and put it in a tube furnace, vacuumize it, use argon as a protective gas (flow rate is 1000sccm), and heat at 10°C / The temperature was raised to 1000°C at a rate of 1 min, the heat treatment time was 2 h under argon, and the temperature was lowered to room temperature under the protection of argon. (Such as Figure 6 Shown) The total mass percentages of carbon nanotubes and graphene in the six samples are: 0, 1wt%, 2wt%, 5wt%, 10wt%, and 20wt%. Figure 9 The scanning electron microscope photos in the paper show that the cotton cloth is woven from regular cotton threads, and the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com