Nano-composite adsorbent preparation method directly processing waste water containing chrome tanning

A nano-composite, adsorbent technology, applied in chemical instruments and methods, animal processing wastewater treatment, adsorbed water/sewage treatment, etc., can solve the problems of difficulty in stability, complex operation, high investment and operating costs, and achieve strong adsorption capacity The effect of low economic cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

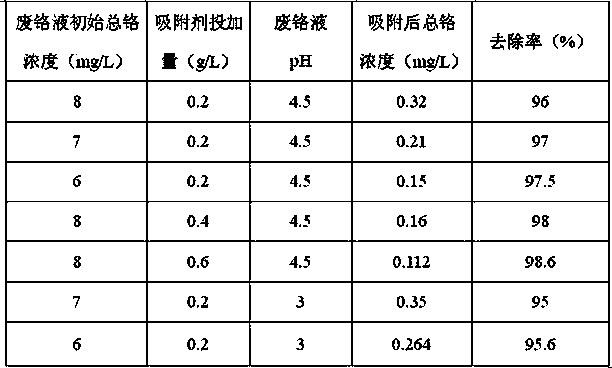

Examples

Embodiment 1

[0014] 1. Nano titanium dioxide (TiO 2 ) into a four-neck flask, add 100 ml of deionized water to disperse to make a solution with a mass concentration of 5%, stir at 800 r / min for 60 min at a constant temperature of 30 °C, and let it stand overnight. Next day, at 50 °C , add 20g of diallyl dimethyl ammonium chloride (DMDAAC), fully stir, ultrasonic treatment, set aside.

[0015] 2. Put 22g of the mixture of acrylamide (AM) and hydroxyethyl acrylate (HEA) into the constant pressure dropping funnel, the mass ratio of AM:HEA is 1:0.7, add 10g of methacrylic acid (MAA) into the second drop In the liquid funnel, the initiator potassium persulfate was added to the third dropping funnel, the amount added was 5% of the total mass of the monomer, the temperature was raised to 80°C, the stirring speed was 200 r / min, and the monomer and the initiator were added dropwise at the same time. The agent was added dropwise in 1 hour, and the reaction was carried out at a constant temperature ...

Embodiment 2

[0019] 1. Nano titanium dioxide (TiO 2 ) into a four-neck flask, add 100 ml of deionized water to disperse to make a solution with a mass concentration of 8%, stir at 800 r / min for 60 min at a constant temperature of 30 °C, and let it stand overnight. Next day, at 50 °C , add 17g of diallyl dimethyl ammonium chloride (DMDAAC), fully stir, ultrasonic treatment, set aside.

[0020] 2. Put 19g of the mixture of acrylamide (AM) and hydroxyethyl acrylate (HEA) into the constant pressure dropping funnel, the mass ratio of AM:HEA is 1:1, add 7g of methacrylic acid (MAA) into the second drop funnel In the liquid funnel, the initiator potassium persulfate was added to the third dropping funnel, the amount added was 3% of the total mass of the monomer, the temperature was raised to 70°C, the stirring speed was 200 r / min, and the monomer and the initiator were added dropwise at the same time. Agent, 1h dropwise completed, constant temperature reaction 3h.

[0021] 3. After the reaction...

Embodiment 3

[0024] 1. Nano titanium dioxide (TiO 2 ) into a four-neck flask, add 100 ml of deionized water to disperse, and make a solution with a mass concentration of 6%. Stir at a constant temperature of 30°C for 60 min at 800 r / min, stand overnight, and the next day, at 50°C , add 22g of diallyl dimethyl ammonium chloride (DMDAAC), fully stir, ultrasonic treatment, set aside.

[0025] 2. Put 25g of the mixture of acrylamide (AM) and hydroxyethyl acrylate (HEA) into the constant pressure dropping funnel, the mass ratio of AM:HEA is 1:1.1, add 12g of methacrylic acid (MAA) into the second drop funnel In the liquid funnel, the initiator potassium persulfate was added to the third dropping funnel, the amount added was 4% of the total mass of the monomer, the temperature was raised to 90°C, the stirring speed was 200 r / min, and the monomer and the initiator were added dropwise at the same time. The agent was added dropwise in 1 hour, and the reaction was carried out at a constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com