Disc type brake performance detection method and the device

A disc brake and detection device technology, which is applied in the direction of measuring devices, mechanical parts testing, force/torque/power measuring instruments, etc., can solve the problem of unsatisfactory integration of monitoring, digitization and networking, and lack of detection brake clearance and brake deceleration, large amount of disc brake changes, etc., to achieve the effect of wide practicability, simple detection method, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

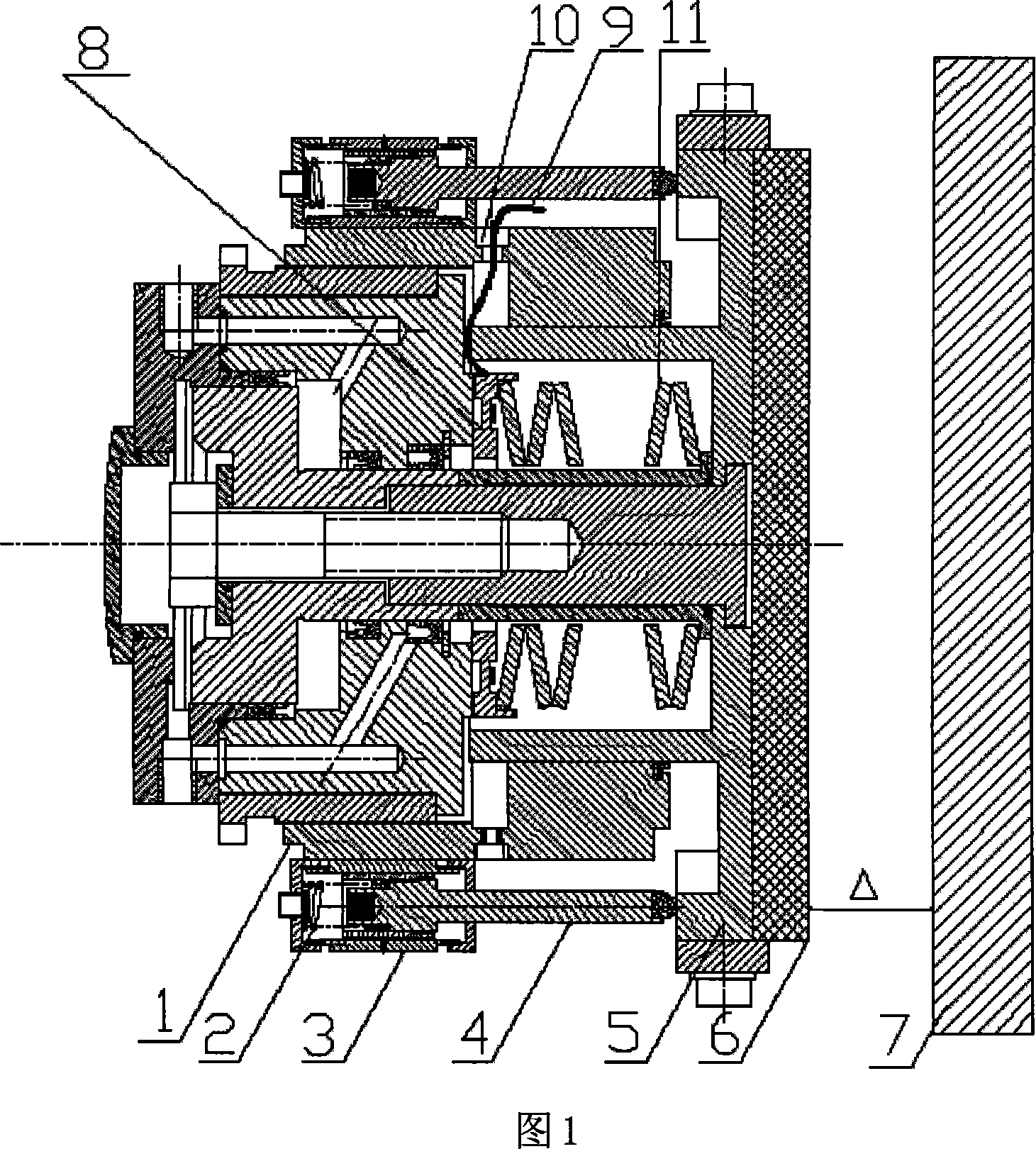

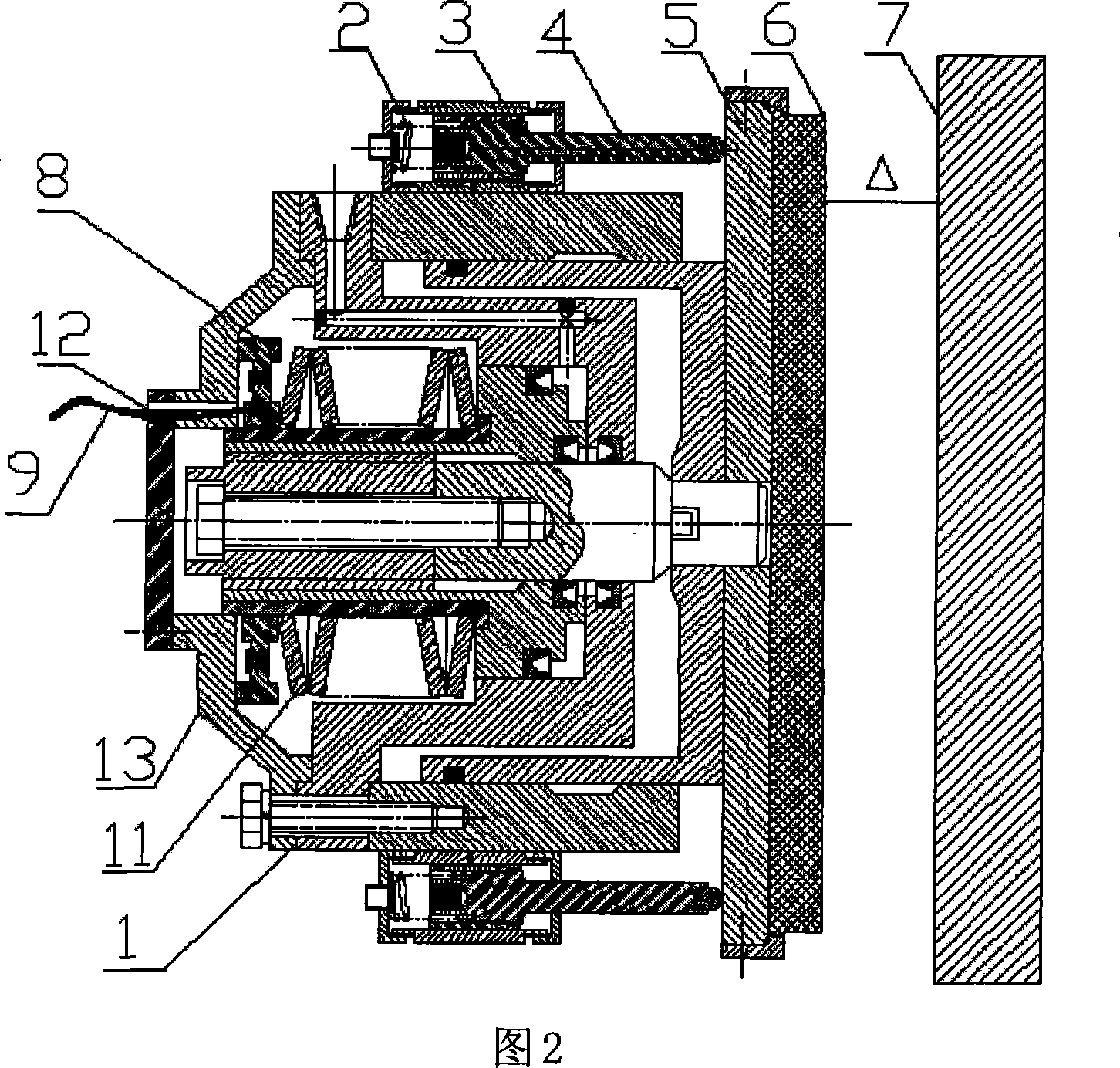

[0018] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

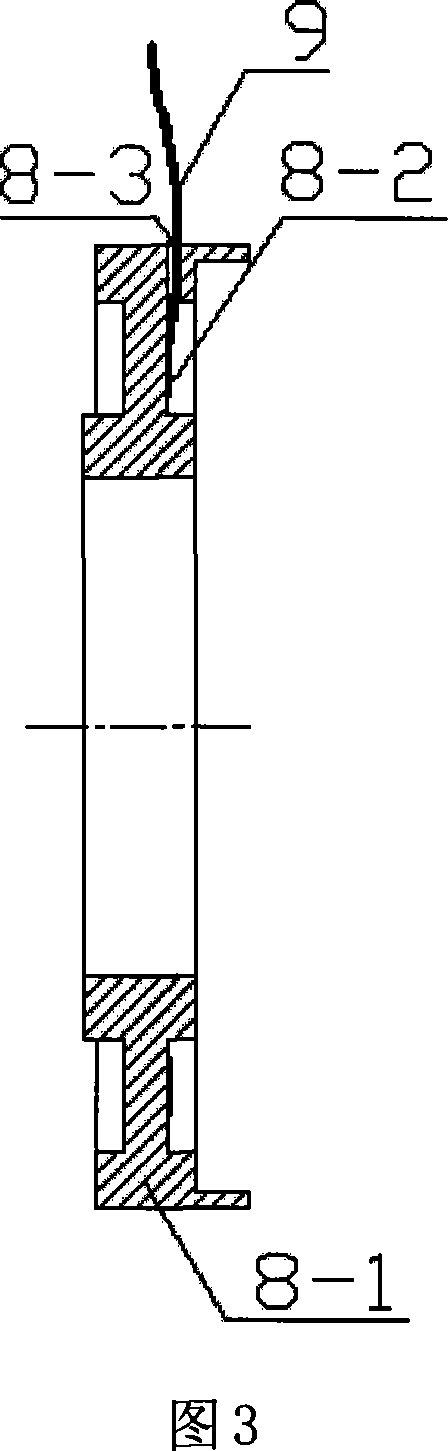

[0019] The brake performance detection method of the disc brake of the present invention adopts a data acquisition and processing system, which integrates brake clearance detection, brake positive pressure detection, idle travel time detection, and brake deceleration detection. The brake pressure of the disc brake is detected by the positive pressure sensor; the displacement is detected by the contact Hall displacement sensor; the detection of the idle travel time and the braking deceleration is completed through the data acquisition and processing system. The specific detection is as follows:

[0020] a. Brake gap detection: fix the front or rear disc brake on the brake seat according to the conventional method, so that it is in the brake state, and the brake gap Δ between the brake shoe 6 and the brake disc 7 is 0. At this time Record the output va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com