Electrically-driven fracturing pump truck

A fracturing pump truck and electric drive technology, which is applied in the direction of motor vehicles, goods transport vehicles, vehicles used for freight, etc., can solve the problem of large size and weight of high-power diesel engines and gearboxes, high-power diesel engines with large noise, and pushing up the overall Operating costs and other issues, to reduce the workload and cost of daily maintenance, energy saving and emission reduction effects, and maintain long-term uninterrupted operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

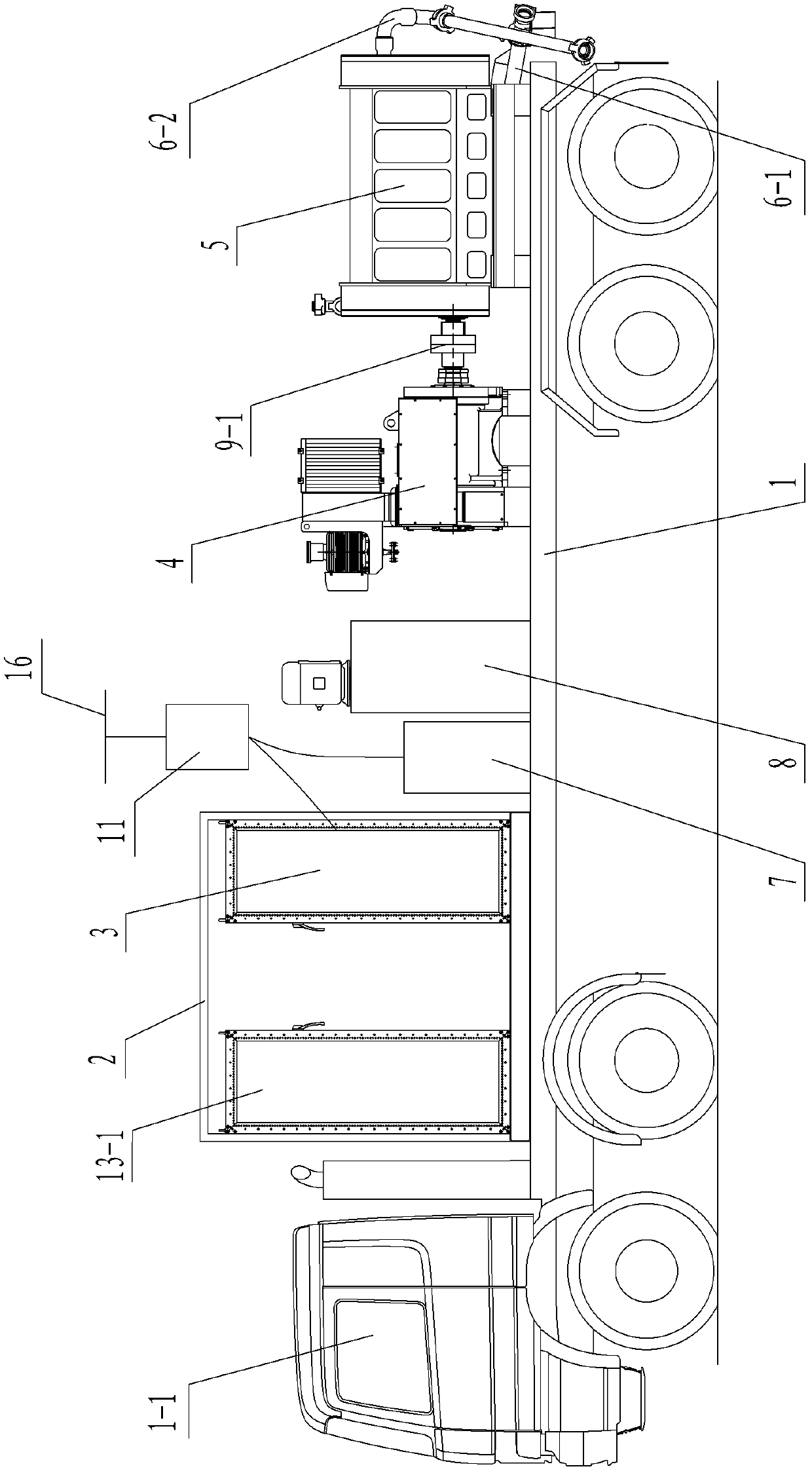

[0046] Such as figure 1 As shown, the present invention includes a truck chassis 1 with a cab 1-1, a lubricating cooling system 8 and a fracturing pump 5 are installed on the truck chassis 1, and a suction manifold 6-1 connected to the fracturing pump 5 and The discharge manifold 6-2, the truck chassis 1 is also equipped with an electric drive system and a control system, the electric drive system includes a motor 4 and a motor drive device 3 for driving the fracturing pump 5, the control system It includes an active power control system 14 for controlling the motor drive device 3 and an auxiliary power control system 15 for controlling the lubrication and cooling system 8. The motor drive device 3, the active power control system 14 and the auxiliary power control system 15 are all connected through external Mains powered.

[0047] In this embodiment, there is one motor 4, and the motor 4 is connected to the fracturing pump 5 through a first coupling 9-1. When the input pow...

Embodiment 2

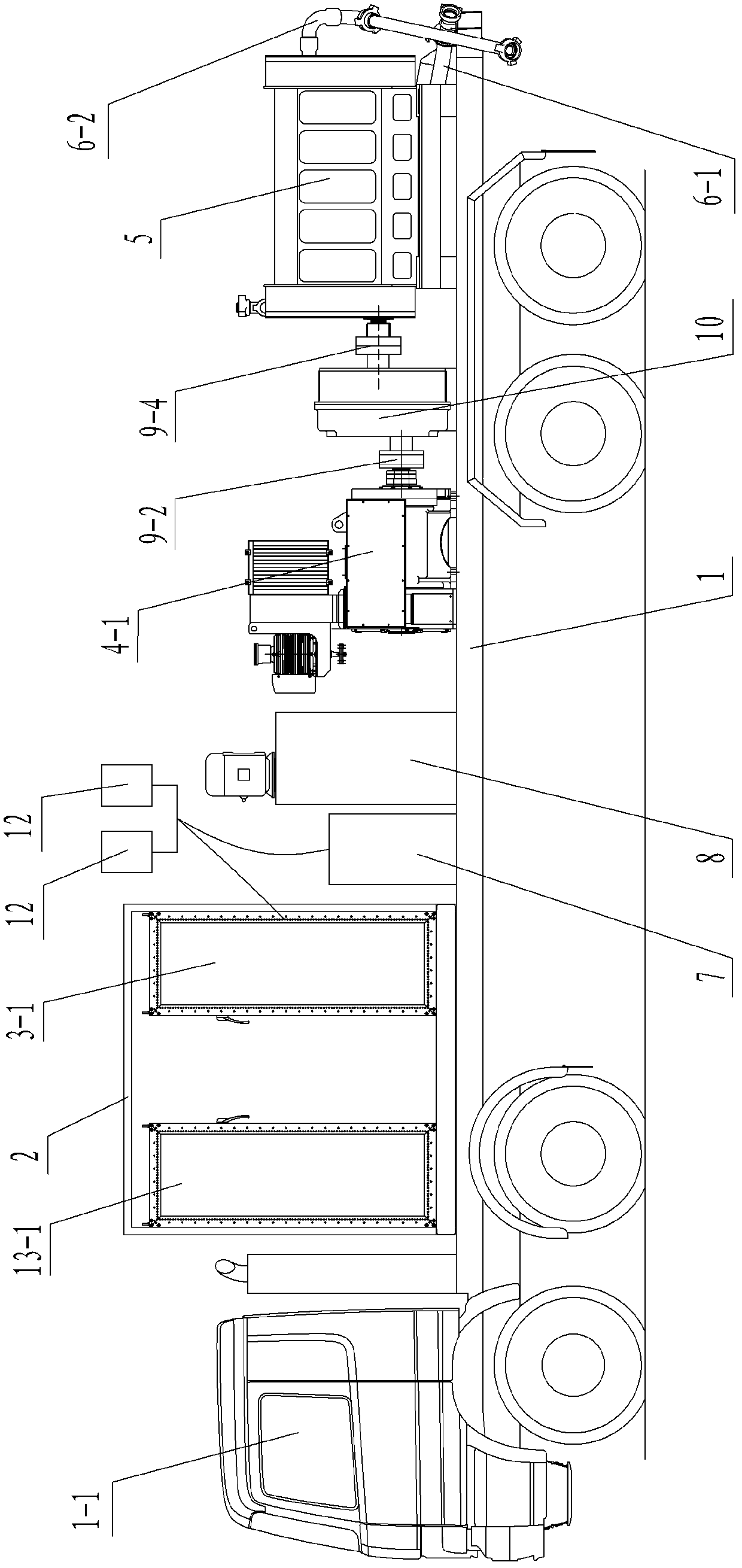

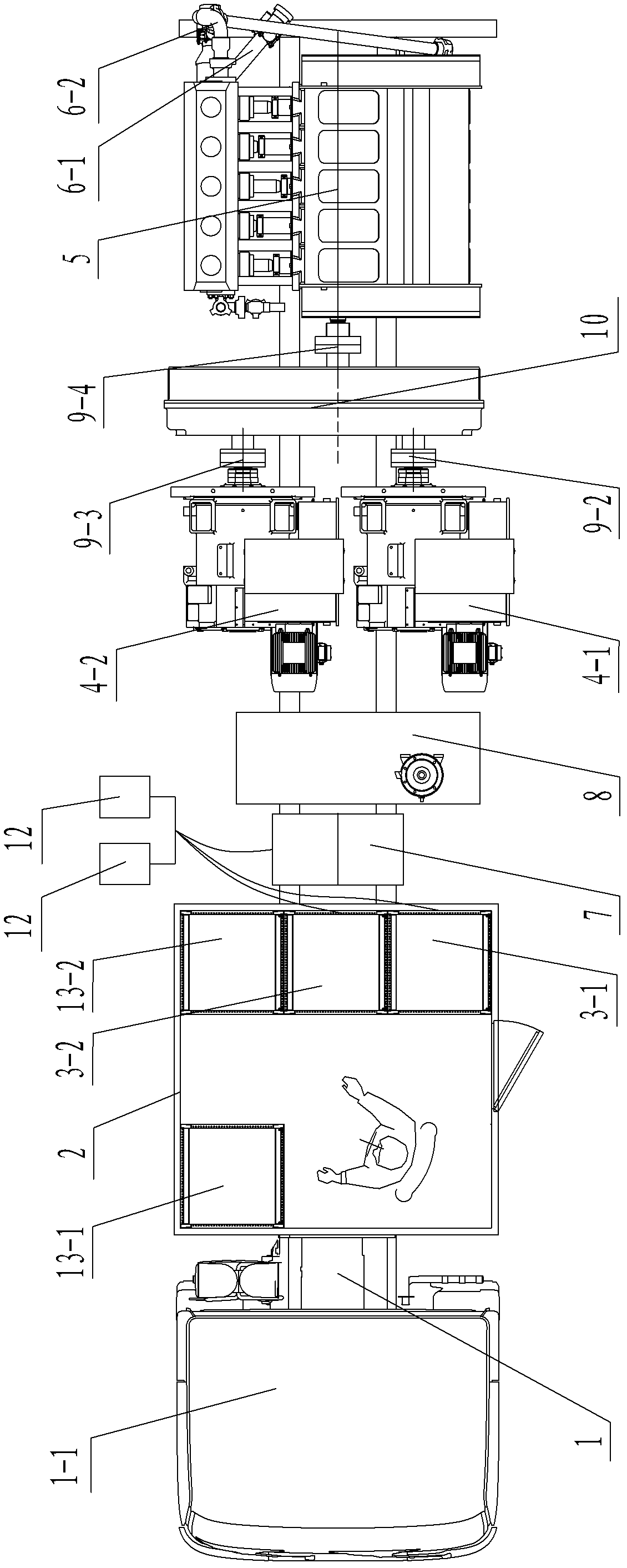

[0053] Such as figure 2 with image 3 As shown, the difference between this embodiment and Embodiment 1 is that there are two motors 4 and they are respectively a first motor 4-1 and a second motor 4-2, and there are two motor drive devices 3 and they are respectively The first motor drive device 3-1 connected to the first motor 4-1 and the second motor drive device 3-2 connected to the second motor 4-2, the electric drive system also includes a gearbox 10, the first An electric motor 4-1 is connected with the gearbox 10 through the second coupling 9-2, and the second motor 4-2 is connected with the gearbox 10 through the third coupling 9-3, and the gearbox 10 is connected with the gearbox 10 through the first The four couplings 9-4 are connected with the fracturing pump 5. The external power supply includes a generator set 12 and an auxiliary transformer 7 connected to the generator set 12, the auxiliary transformer 7 is installed on the truck chassis 1, the motor drive de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com