Speed control for a pumping system

a technology of speed control and pumping system, which is applied in the direction of pump control, positive displacement liquid engine, non-positive displacement fluid engine, etc., can solve the problems of increasing current and power drawn, centrifugal pump does not lend itself to higher head applications, etc., and achieves the effect of reducing the load of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

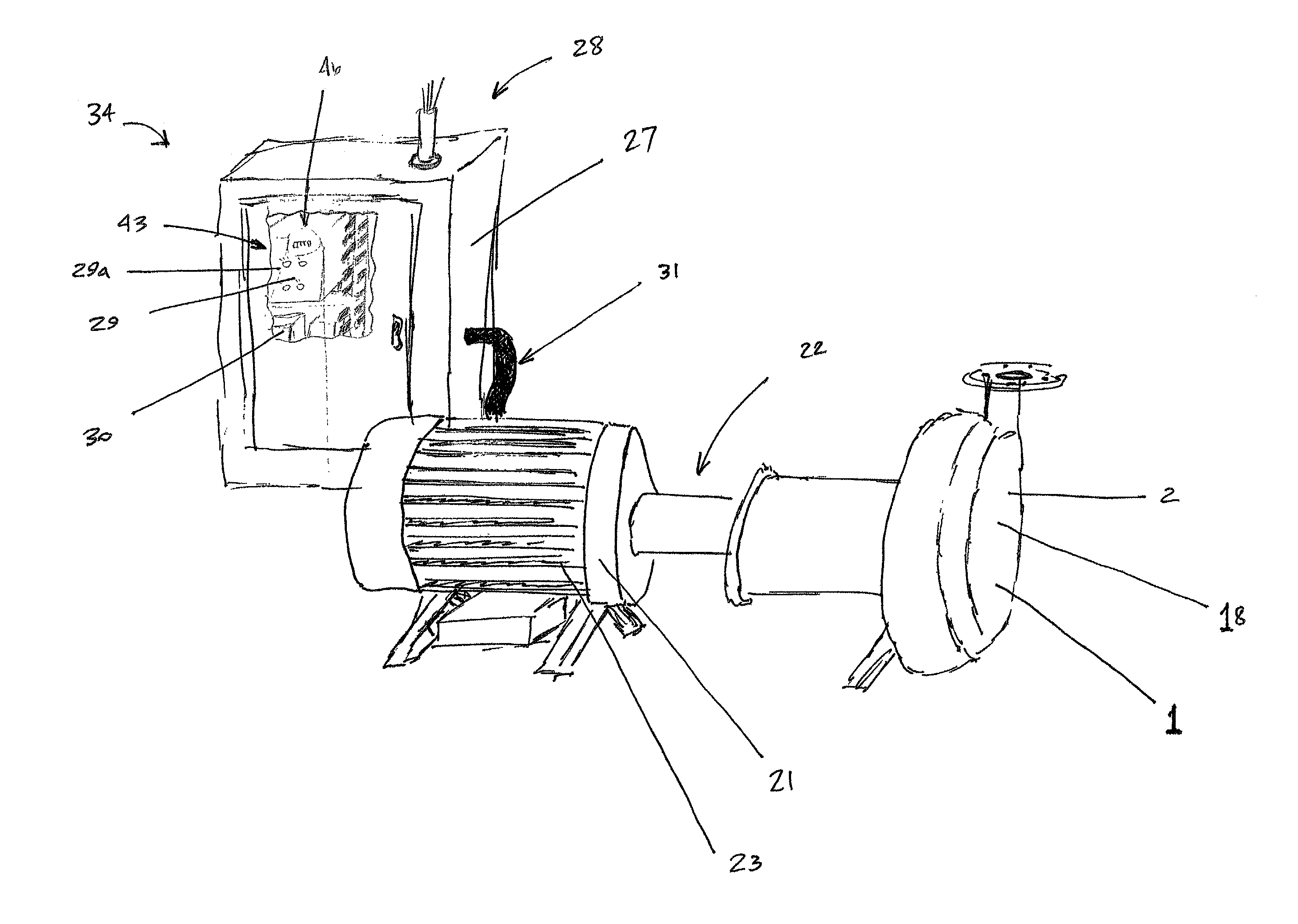

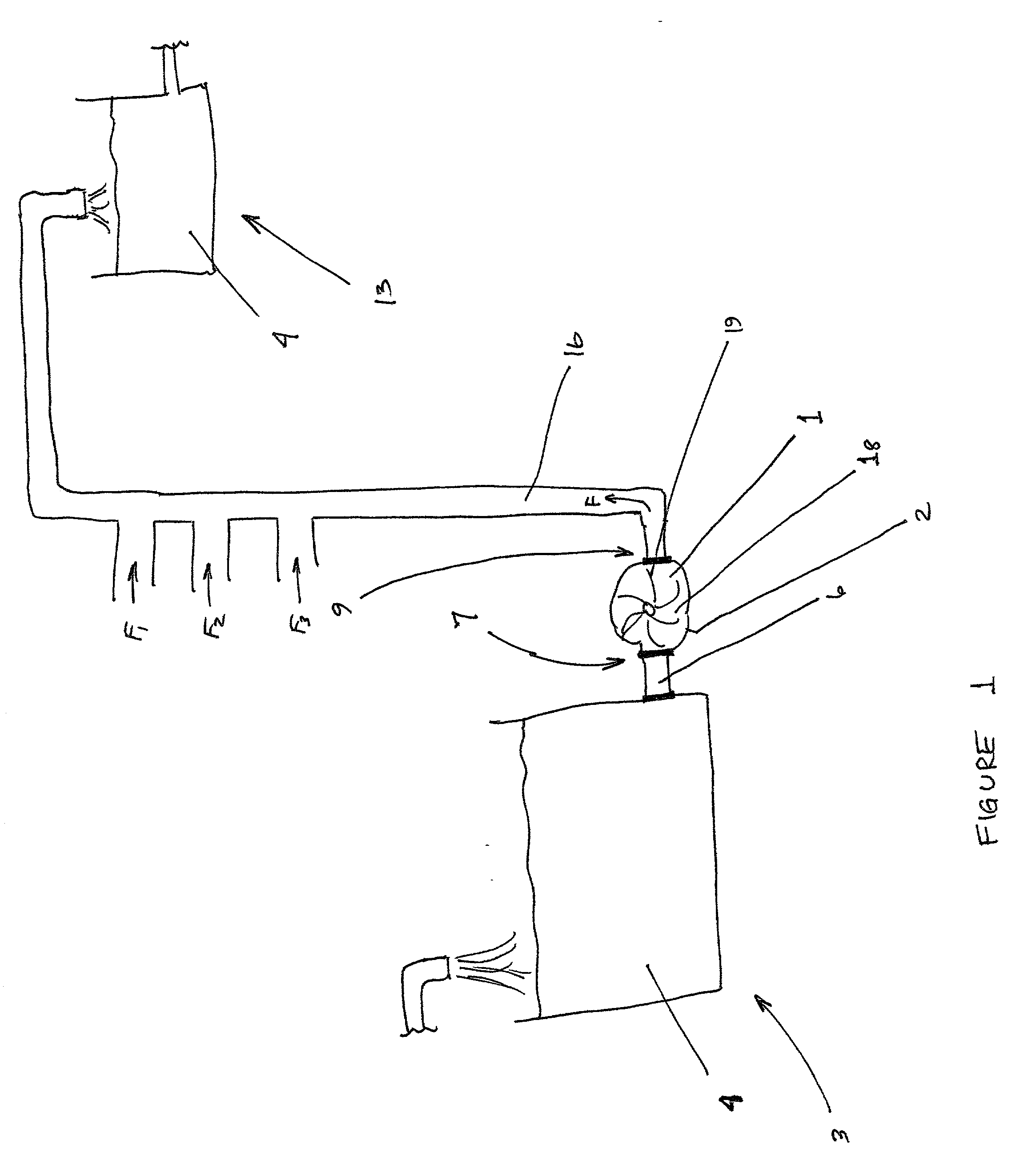

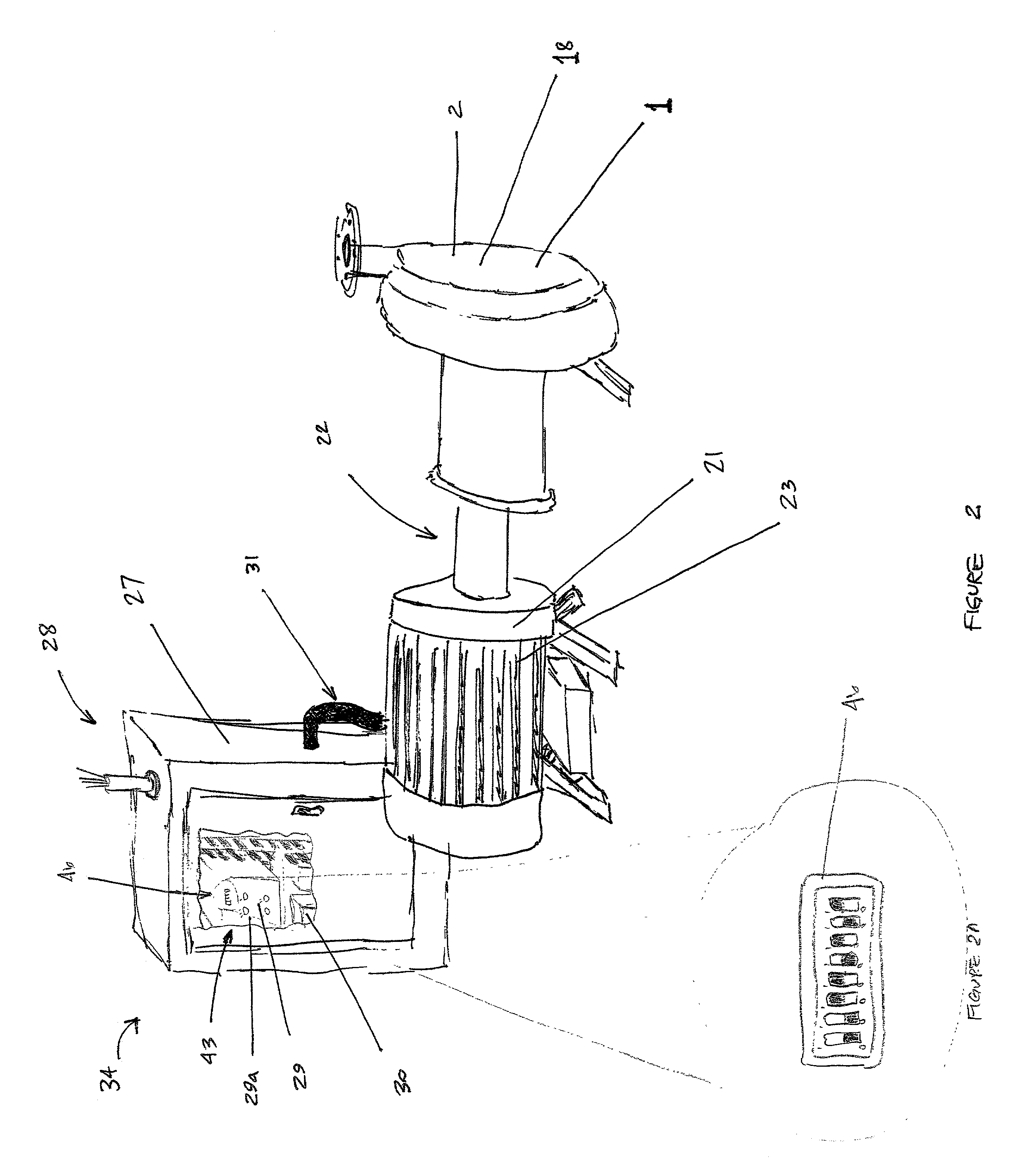

[0019] Referring now to the drawings wherein the showings are for purposes of illustrating a preferred embodiment of the invention only and not for purposes of limiting the same, FIG. 1 depicts a schematic representation of a wastewater pump 1 operatively connected to a supply source 3 of slurry mixture 4 via a slurry inlet conduit 6. The wastewater pump 1 may include an inlet 7 for use in receiving the slurry mixture 4 from the slurry conduit 6. The wastewater pump 1 may also include an impeller 19, shown in FIG. 6, for use in pumping the slurry mixture 4 via an outlet 9 to a discharge tank 13 or other storage means. In this manner, the slurry mixture 4 is transmitted through the body 2 of the pump 1. The outlet 9 of the wastewater pump 1 may be connected to the discharge tank 13 via slurry outlet conduit 16. It is noted that any configuration of supply source and discharge tank storage means for containing the slurry mixture may be chosen with sound engineering as is appropriate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com