Engineering vehicle and engine rotating speed control system and method thereof

A technology of engine speed and engineering vehicles, which is applied in engine control, machine/engine, electrical control, etc., can solve the problems of large number of sensors, high cost, high failure rate, etc., to reduce fuel consumption, realize simple and reliable, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

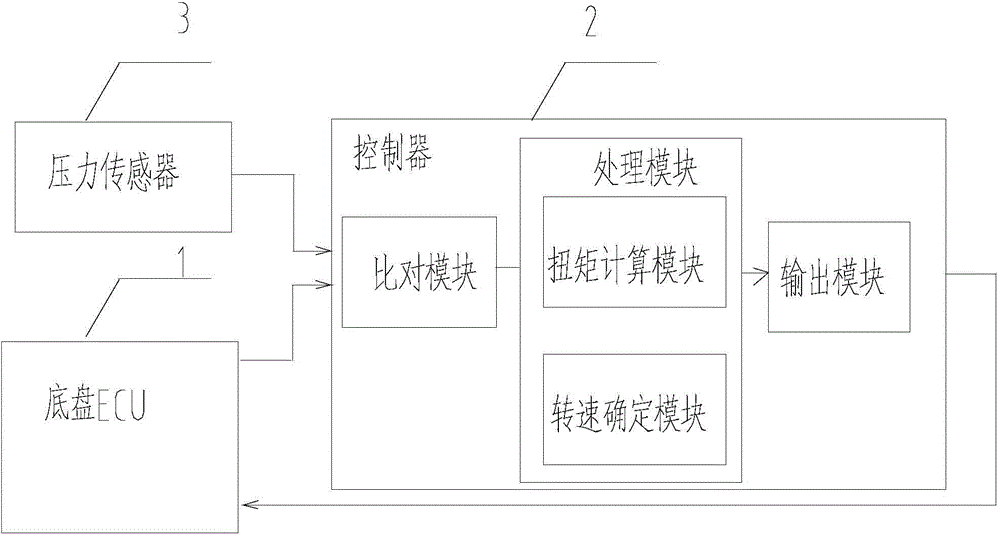

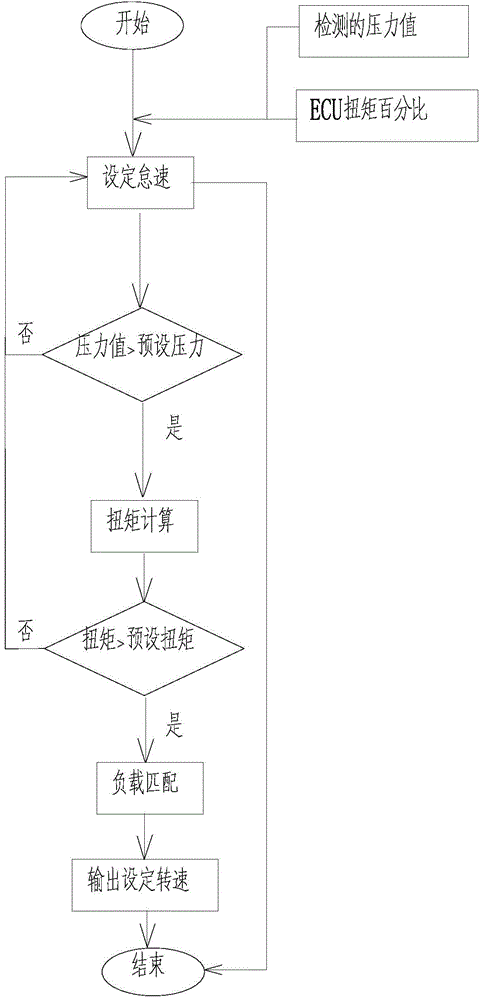

[0021] figure 1 A schematic structural diagram of an engine speed control system of an engineering vehicle provided in an embodiment of the present invention; figure 1 As shown, the engine speed control system includes: chassis ECU (Electronic Control Unit, electronic control unit) 1, used to send the first message including the current torque percentage, and receive the second message including the set speed, wherein, The current torque percentage is equal to the ratio of the current torque of the engine to the limit torque of the engine, so the current torque can be determined by calculating the product of the current torque percentage and the limit torque of the engine; the controller 2 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com