Continuous acid mixing equipment

A kind of acid mixing equipment and acid mixing technology, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of cost waste, volatile acid liquid, occupation, etc., and achieve the effect of safe operation performance and continuous mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

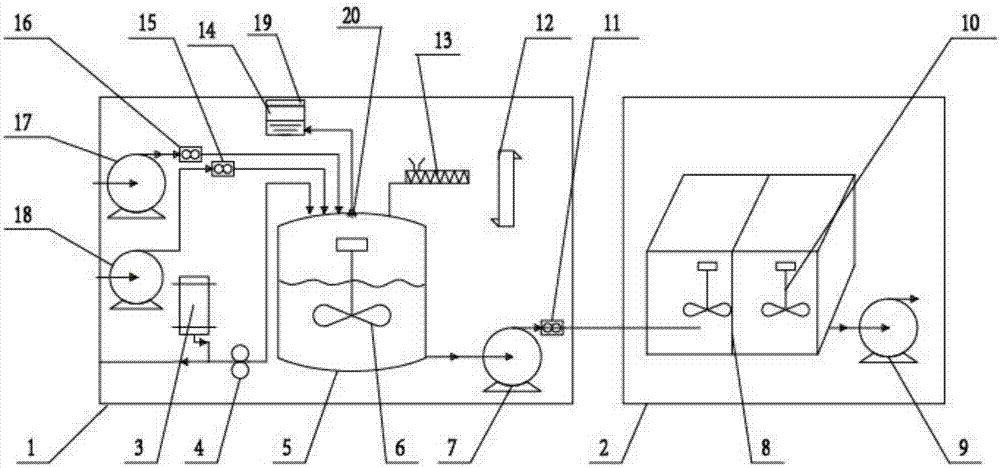

[0020] A continuous acid mixing equipment, such as figure 1 As shown, it includes a continuous acid distribution vehicle and a skid-mounted buffer tank. The continuous acid distribution vehicle includes a chassis vehicle 1 and a liquid addition pump 4 placed on the chassis vehicle 1, a raw acid centrifugal pump 17, a clean water centrifugal pump 18, and a discharge centrifugal pump 1. Pump 7, mixed acid tank 5, acid-base tank 14, automatic feeder 12 and dry powder adding device 13, described clear water centrifugal pump 18 is connected with mixed acid tank 5 through the clear water manifold that comprises clear water flowmeter 15 and pipeline, and described original The acid centrifugal pump 17 is connected to the acid mixing tank 5 through the original acid manifold comprising the original acid flow meter 16 and the pipeline, and the inside of the tank top of the mixing acid tank 5 is provided with a first agitator 6 and a solid conical nozzle 20, the nozzle The cone angle of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com