Anodic oxide film and methods for manufacturing same

A technology of anodic oxidation film and production method, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problem of large energy consumption and achieve high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

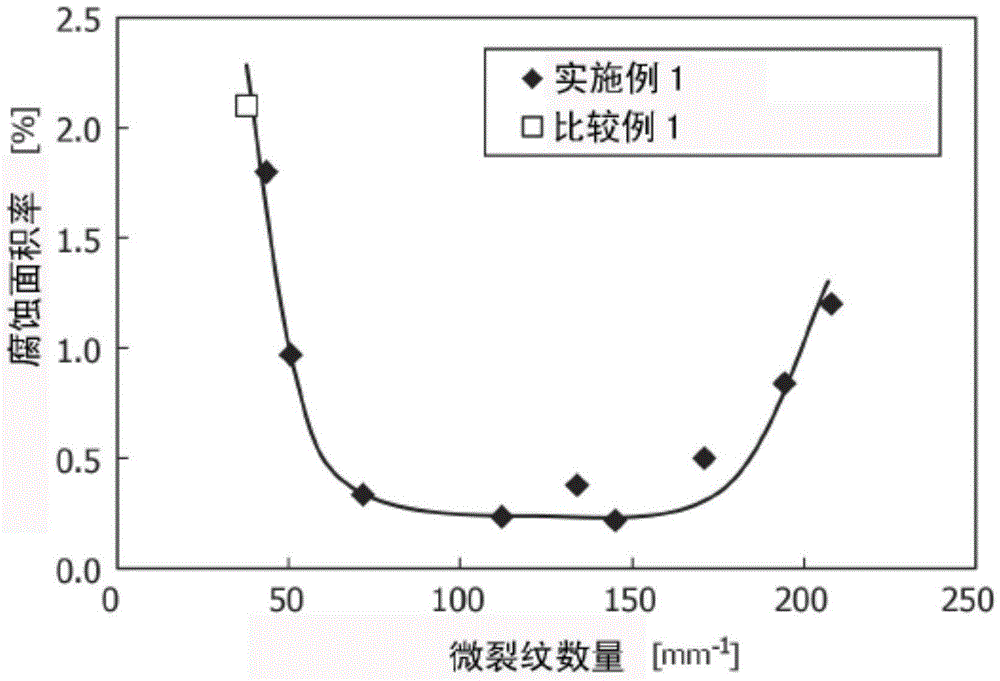

[0059] A test piece of an aluminum alloy die-casting material ADC12 was used. Immerse each test piece as an anode in a 200g / L sulfuric acid bath, and apply a current density of 1.5A / dm 2 DC current for 10 minutes. Thus, an anodized film having a film thickness of 3 μm was formed. After the anodizing treatment, the sealing treatment was carried out by immersing the test piece in a sealing treatment solution containing 0.8 g / L lithium ions, pH 12, and a temperature of 40° C. for 1 minute. Then, the test piece was dried in an oven at 120° C. for 30 minutes. The dried test piece is then heat-treated in an oven at 120-400° C. for 30-300 minutes. The number of microcracks on the anodized film surface of the obtained test piece was measured. In addition, corrosion resistance was evaluated by performing a salt spray test (JIS Z2371) for 240 hours. In order to evaluate the corrosion resistance, the corrosion area ratio was calculated according to the following formula (1):

[006...

Embodiment 2

[0069] Example 2 was carried out in the same manner as Example 1.

Embodiment 3

[0077] A test piece of an aluminum alloy die-casting material ADC12 was used. Immerse each test piece as an anode in a 200g / L sulfuric acid bath, and apply a current density of 1.5A / dm 2 DC current for 10 minutes. Thus, an anodized film having a film thickness of 3 μm was formed. After the anodizing treatment, sealing treatment was performed by immersing the test piece in a sealing treatment solution containing 0.8 g / L lithium ions, pH 12, and temperature 40° C. for 1 minute. Then, the test piece was dried in an oven at 120° C. for 30 minutes. The dried test piece was further heat-treated in an oven at 400° C. for 30 minutes.

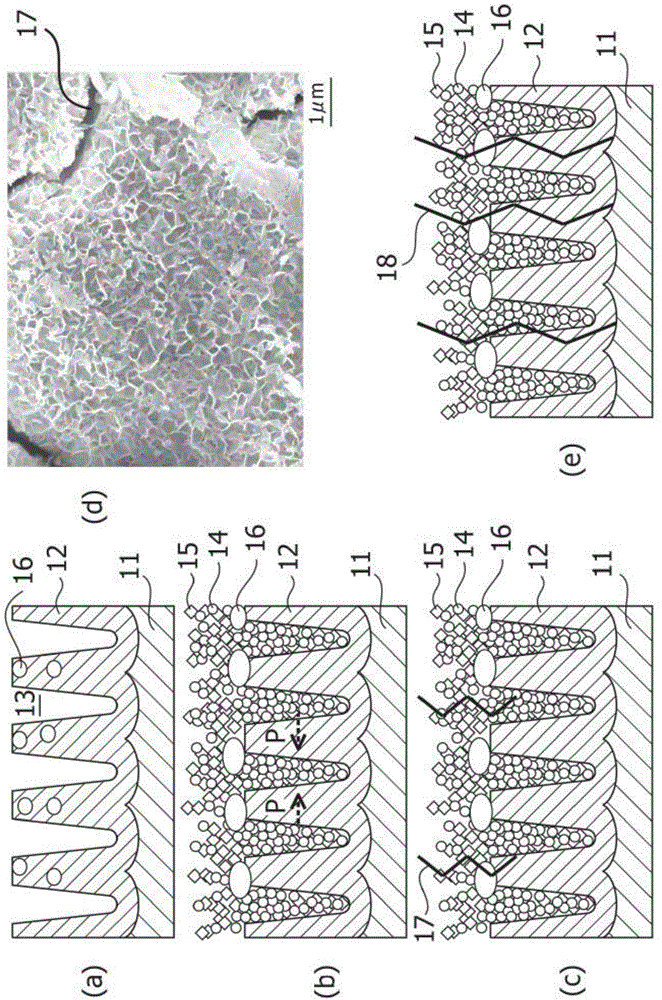

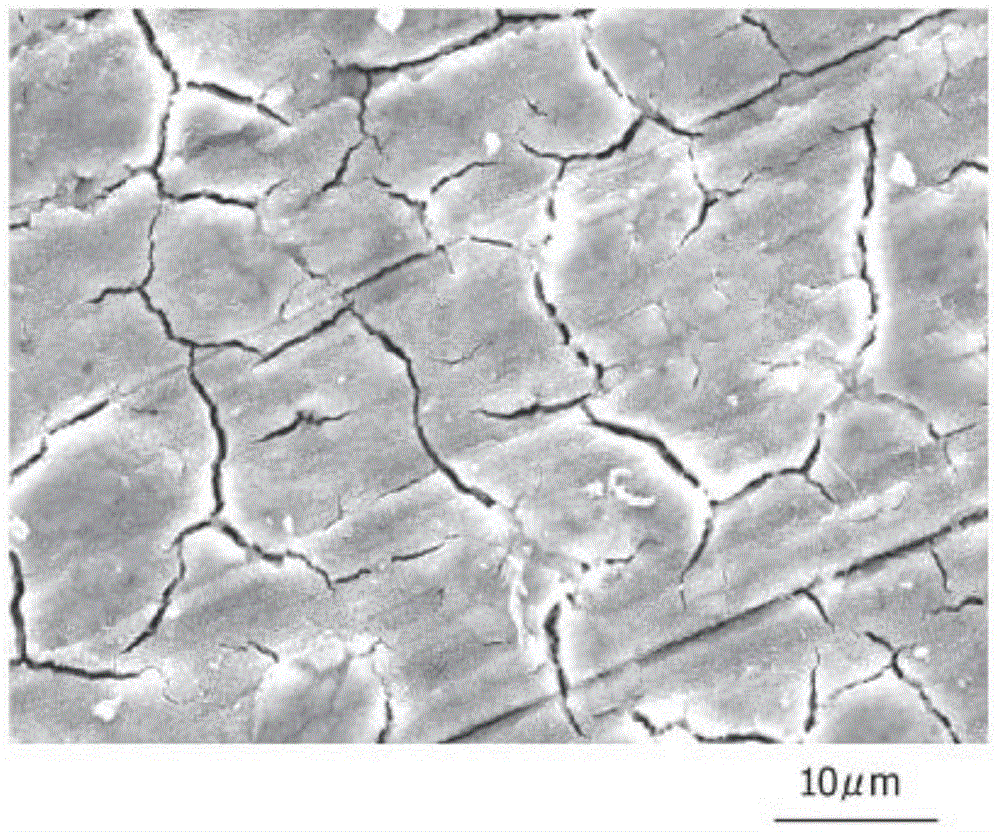

[0078] Cross-sectional photographs of the obtained test piece before and after heat treatment were taken by FE-SEM.

[0079] In general, when an anodized film is formed on an aluminum alloy material containing a large amount of silicon such as an aluminum die-casting material, a thick film is formed at a portion with a low silicon content and a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com