Method and apparatus for rapid preparation of anodic oxidation film on aluminium alloy products

A technology of anodized film and aluminum alloy, applied in the direction of anodization, electrolysis process, electrolysis components, etc., can solve problems such as less than 25% and can not fully meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

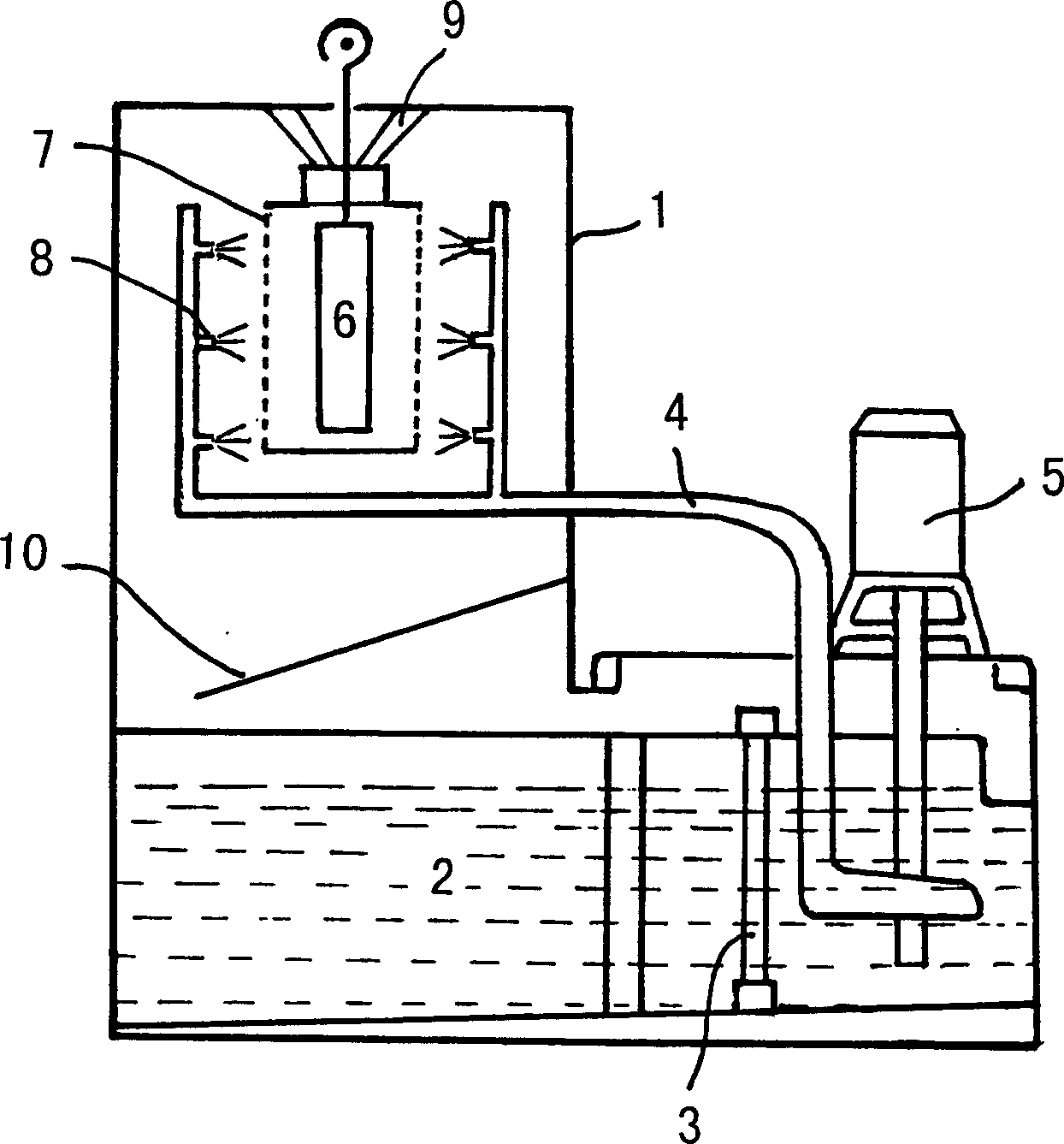

[0011] A device for quickly preparing anodic oxide film on an aluminum wheel hub. The aluminum wheel hub is used as the anode 6, suspended by a hook and located on the upper part of the housing 1, and the auxiliary cathodes 7 are respectively arranged on both sides of the anode 6. The pipeline 4 is equipped with a plurality of nozzles 8, the electrolyte in the liquid storage tank 2 is sent to the nozzles through the pump 5 and the pipeline 4, and the electrolyte sprayed from the nozzles 8 passes through the auxiliary cathode 7 and is continuously sprayed on the anode 6 , an exhaust fan 9 and a deflector 10 are respectively arranged above and below the anode 6; the distance between the nozzle 8 and the anode 6 is 250 mm, the distance between the auxiliary cathode 7 and the anode 6 is 100 mm, and the distance between the auxiliary cathode 7 and the anode 6 is 100 mm. The voltage between the anodes 6 is 20, and the auxiliary cathode 7 adopts titanium mesh coated with lead dioxide,...

Embodiment 2

[0013] A device for quickly preparing anodic oxide film on an aluminum wheel hub. The aluminum wheel hub is used as the anode 6, suspended by a hook and located on the upper part of the housing 1, and the auxiliary cathodes 7 are respectively arranged on both sides of the anode 6. The pipeline 4 is equipped with a plurality of nozzles 8, the electrolyte in the liquid storage tank 2 is sent to the nozzles through the pump 5 and the pipeline 4, and the electrolyte sprayed from the nozzles 8 passes through the auxiliary cathode 7 and is continuously sprayed on the anode 6 , an exhaust fan 9 and a deflector 10 are respectively arranged above and below the anode 6; the distance between the nozzle 8 and the anode 6 is 300 mm, the distance between the auxiliary cathode 7 and the anode 6 is 100 mm, and the auxiliary cathode 7 and The voltage between the anodes 6 is 30V, and the auxiliary cathode 7 adopts titanium mesh coated with lead dioxide, uses 30% sulfuric acid as electrolyte, and...

Embodiment 3

[0015] An equipment for quickly preparing anodized film on an aluminum alloy decorative plate. The aluminum alloy decorative plate is used as the anode 6, suspended by a hook and located on the upper part of the housing 1, and the auxiliary cathodes 7 are respectively arranged on both sides of the anode 6, located on the auxiliary The pipeline 4 outside the cathode 7 is equipped with a plurality of nozzles 8, the electrolyte in the liquid storage tank 2 is sent to the nozzles through the pump 5 and the pipeline 4, and the electrolyte sprayed from the nozzles 8 passes through the auxiliary cathode 7 and sprays continuously On the anode 6, an exhaust fan 9 and a deflector 10 are respectively arranged above and below the anode 6; the distance between the nozzle 8 and the anode 6 is 275 mm, and the distance between the auxiliary cathode 7 and the anode 6 is 100 mm. The voltage between the auxiliary cathode 7 and the anode 6 is 25V, 20% sulfuric acid is used as the electrolyte, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com