Paste forming body for water-based aluminum-based soldering paste and water-based aluminum-based soldering paste

A paste-forming, aluminum-based technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as unfavorable health of workers and environmental protection, heavy odor, welding failure, etc., and achieve increased storage stability Sex, increase the activity of solder paste, avoid the effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

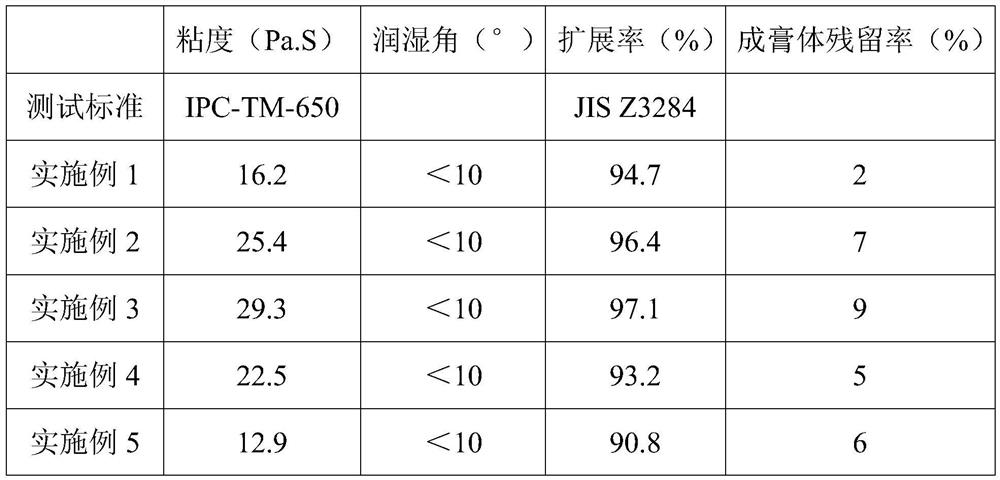

Embodiment 1

[0029] A water-based aluminum-based solder paste is composed of the following components by weight percentage: Si10Al90 alloy powder (with a particle size range of 100-200 mesh) 55%, potassium fluoroaluminate flux powder (with a particle size range of 500-1000 mesh) ) 22%, forming paste Ⅰ 7% and forming paste Ⅱ 16%;

[0030] Wherein, paste I includes the following components in mass percentage: 0.3% styrene-butadiene-styrene block copolymer, 97% isomerized hexadecane, polyacrylamide isoparaffin lauryl ether (305 emulsified agent) 2.7%; forming paste II includes the following components in mass percentage: methyl cellulose 2.6%, hydroxypropyl cellulose 3.2%, isopropanol 6.3%, ethylene glycol 9.5%, deionized water 78.4%.

[0031] The preparation of the above-mentioned water-based aluminum-based solder paste specifically includes: weighing according to the composition of the aluminum-based solder paste, adding the paste I into the Si10Al90 alloy powder and stirring for 30 minutes...

Embodiment 2

[0033] A water-based aluminum-based solder paste is composed of the following components by weight percentage: Si12Cu10Al78 alloy powder (with a particle size range of 100-200 mesh) 55%, potassium fluoroaluminate flux powder (with a particle size range of 500-1000 mesh) ) 20%, cesium fluoroaluminate flux powder (the particle size range is 500-1000 mesh) 2%, forming paste I 7% and forming paste II 16%;

[0034] Wherein, paste I includes the following components in mass percentage: 0.3% styrene-butadiene-styrene block copolymer, 97% isomerized hexadecane, polyacrylamide isoparaffin lauryl ether (305 emulsified agent) 2.7%; forming paste II includes the following components in mass percentage: 3.3% hydroxyethyl cellulose, 5.5% polyvinylpyrrolidone, 3.4% ethanol, 9.4% propylene glycol, 56.8% deionized water, and 21.6% formamide.

[0035] The preparation of the above-mentioned water-based aluminum-based solder paste specifically includes: weighing according to the composition of th...

Embodiment 3

[0037] A water-based aluminum-based solder paste is composed of the following components by weight percentage: Si12Cu5Zn15Al68 alloy powder (with a particle size range of 100-200 mesh) 60%, potassium fluoroaluminate flux powder (with a particle size range of 500-1000 mesh) ) 16%, cesium fluoroaluminate flux powder (the particle size range is 500-1000 mesh) 4%, forming paste I 10% and forming paste II 10%;

[0038] Wherein, paste I includes the following components in mass percentage: 0.3% styrene-butadiene-styrene block copolymer, 97% isomerized hexadecane, polyacrylamide isoparaffin lauryl ether (305 emulsified agent) 2.7%; forming paste II includes the following components in mass percentage: sodium carboxymethylcellulose 4.6%, polyethylene oxide 4.2%, ethanol 5.6%, glycerol 10.2%, deionized water 47.4%, N- Methylpyrrolidone 28.0%.

[0039]The preparation of the above-mentioned water-based aluminum-based solder paste specifically includes: weighing according to the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com