Grid alloy for single-walled carbon nano-tube storage battery and preparation method thereof

A single-wall carbon nanotube, battery plate technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of hydrogen evolution, water loss and self-discharge increase of batteries, water loss , Reduce the potential of hydrogen evolution of the negative electrode, etc., to achieve the effect of superior current distribution capacity, prevent battery water loss, and reduce capital backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

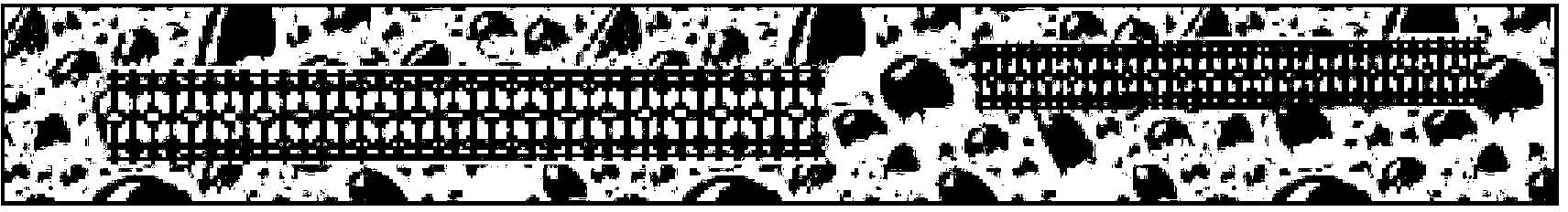

[0036] Single-walled carbon nanotubes with a diameter of 1.5 nm react with anionic surfactants to make a single-walled carbon nanotube solution, add copper sulfate solution to the solution, dry and crystallize the unnecessary components, and combine with copper oxide and oxide Tin is mixed and stirred evenly, aluminum is added and reduced by vacuum melting at 800°C to obtain a single-walled carbon nanotube master alloy, which is added to lead at a ratio of 1:10 and melted at 550°C to cast it into a battery grid. The resistivity of the grid at room temperature is 0.2 ohm·mm2 / m, which is close to that of pure lead. The instant Brinell hardness of the grid is 25-28, and the Brinell hardness after aging for 7 days is 29-33.

[0037] The grid alloy prepared in this embodiment contains: the mass content of single-walled carbon nanotubes is 0.01%, the copper content is 0.01%, the tin content is 0.25%, the aluminum content is 0.001%, and the balance is lead.

Embodiment 2

[0039] Single-walled carbon nanotubes with a diameter of 1.5 nm were mixed with copper oxide and tin oxide and stirred evenly, then aluminum was added and reduced by vacuum melting at 780 °C to obtain a single-walled carbon nanotube master alloy, which was added to lead and mixed with lead at a ratio of 1:10. Melted at 550°C, cast into battery grids.

[0040] The resistivity of the grid at room temperature is 0.2 ohm·mm2 / m, which is close to that of pure lead. The instant Brinell hardness of the grid is 27-28, and the Brinell hardness after aging for 7 days is 30-31.

[0041] The grid alloy prepared in this embodiment contains: the mass content of single-walled carbon nanotubes is 0.015%, the copper content is 0.012%, the tin content is 0.3%, the aluminum content is 0.0012%, and the balance is lead.

Embodiment 3

[0043] Single-walled carbon nanotubes with a diameter of 4 nm react with anionic surfactants to make a single-walled carbon nanotube solution, add copper sulfate solution to the solution, dry and crystallize unnecessary components, and combine with copper oxide and oxide Tin is mixed and stirred evenly, aluminum is added and reduced by vacuum melting at 750°C to obtain a single-walled carbon nanotube master alloy, which is added to lead at a ratio of 1:11 and melted at 550°C to cast it into a battery grid.

[0044] The resistivity of the grid at room temperature is 0.2 ohm·mm2 / m, which is close to that of pure lead. The instant Brinell hardness of the grid is 25-26, and the Brinell hardness after aging for 7 days is 29-30.

[0045] The grid alloy prepared in this embodiment contains: the mass content of single-walled carbon nanotubes is 0.018%, the content of copper is 0.016%, the content of tin is 0.32%, the content of aluminum is 0.0011%, and the balance is lead.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com