Power type lead accumulator positive grid alloy and preparation method thereof

A technology for lead-acid batteries and positive plates, which is applied in the formulation and preparation of positive grid alloys for power-type lead-acid batteries, can solve problems such as corrosion and fracture of positive grid alloys, and achieve improved utilization, elimination of capacity loss, and low melting temperature Effect

Active Publication Date: 2017-05-10

HENAN CHAOWEI POWER SUPPLY

View PDF11 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

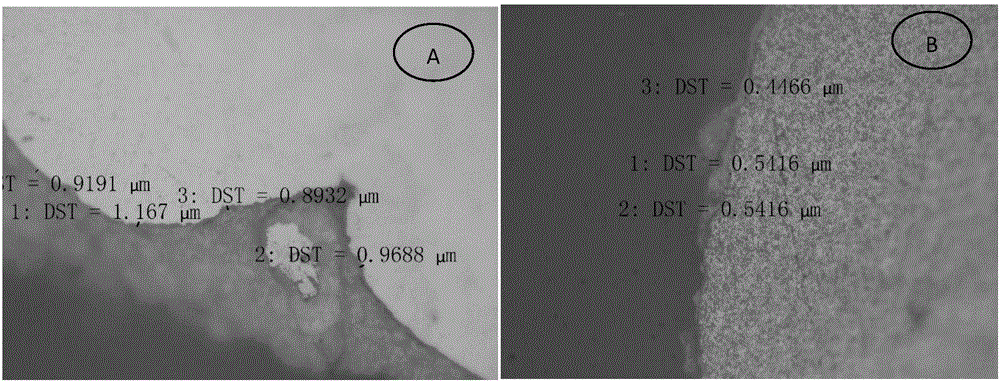

[0004] In order to solve the problem of corrosion and cracking of the positive grid alloy of lead-acid batteries, the present invention proposes a new grid alloy formula, which improves the corrosion resistance and electrical conductivity of the positive grid alloy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

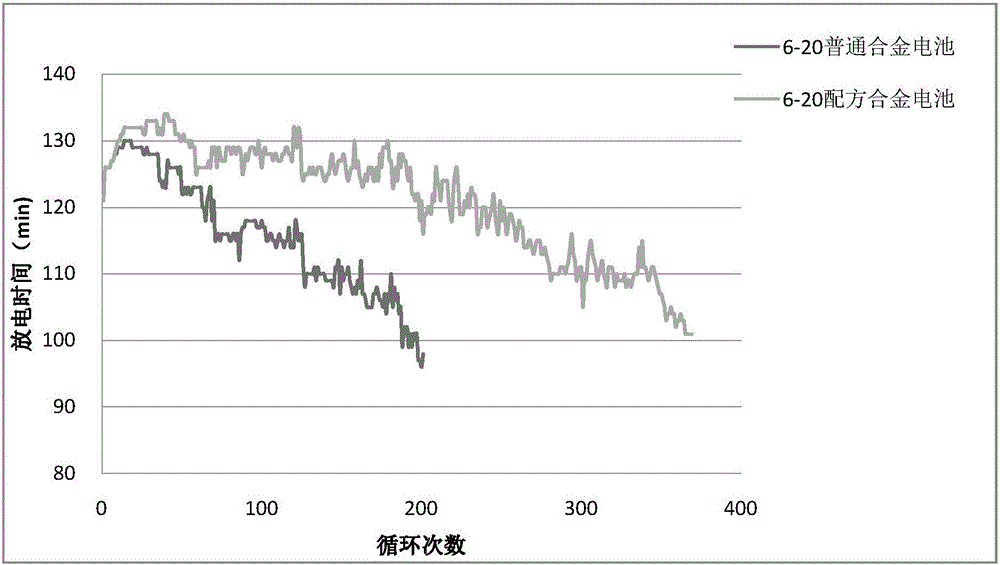

Effect test

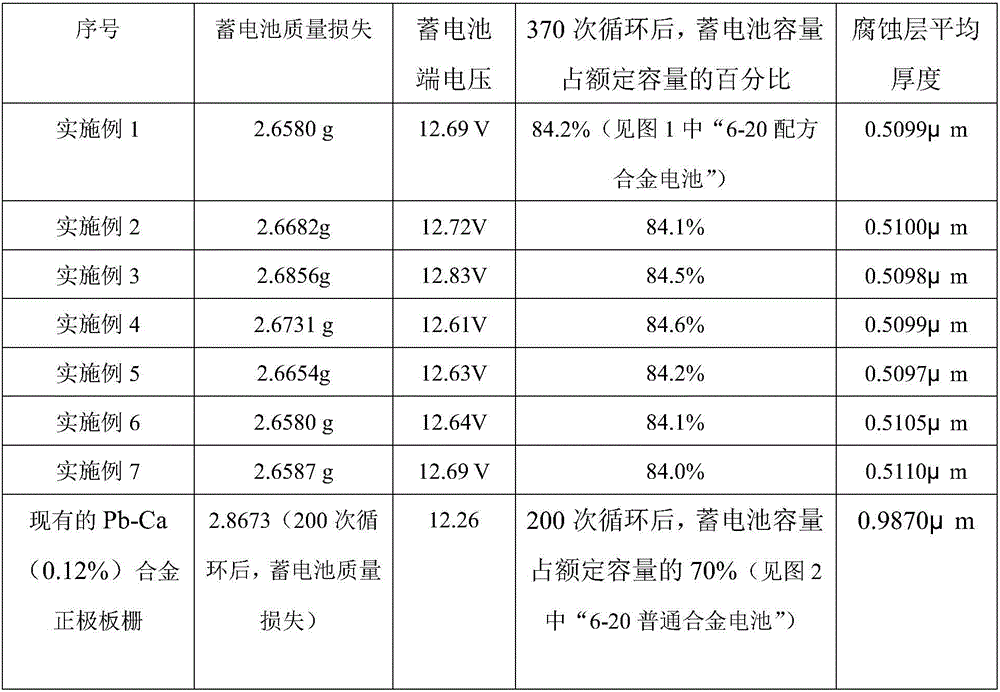

Embodiment 1

[0025] A positive electrode grid alloy for a power type lead storage battery, the weight ratio of raw materials is as shown in Example 1 of Table 1.

Embodiment 2

[0027] A power-type lead storage battery positive electrode grid alloy, the weight ratio of raw materials is as shown in Example 2 of Table 1.

Embodiment 3

[0029] A power-type lead storage battery positive electrode grid alloy, the weight ratio of raw materials is as shown in Example 3 of Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of lead-acid accumulators, and particularly relates to a power type lead accumulator positive grid alloy formula and a preparation method thereof. The alloy comprises the following raw materials in percentage by weight: 0.03-0.12% of calcium, 0.03-1.50% of tin, 0.01-0.05% of aluminum, 0.04-0.08% of sodium, 0.008-0.016% of silver, 0.02-0.03% of bismuth and the balance of Pb. A preparation process of a positive grid comprises the following steps: adding tin, silver and bismuth which are less prone to air oxidation and a small amount of aluminum into molten lead; and then adding sodium and calcium which are prone to air oxidation, wherein the first added aluminum can be floated on the surface of the molten lead alloy to protect the later added sodium and calcium. Thus, the composition uniformity of the molten alloy is ensured.

Description

technical field [0001] The invention belongs to the technical field of lead-acid batteries, and in particular relates to a formula and a preparation method of a positive electrode grid alloy of a power-type lead-acid battery. Background technique [0002] Due to its mature technology, safety and reliability, rich raw materials, low price, and recyclable characteristics, lead-acid batteries have become the preferred power devices for electric bicycles and electric motorcycles. Occupies more than 90% of the battery market for electric bicycle batteries. In order to ensure the service life of electric vehicle batteries, grid alloys that are resistant to corrosion under strong acid and strong oxidation conditions must be used. [0003] At present, lead-calcium-tin-aluminum quaternary alloy is generally used as the positive electrode grid alloy for electric vehicles, but this composition alloy still cannot meet the requirements of the battery, and corrosion and fracture of the g...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C11/00C22C11/02C22C11/06C22C1/02H01M4/68H01M4/73

CPCC22C1/02C22C11/00C22C11/02C22C11/06H01M4/685H01M4/73Y02E60/10

Inventor 闫新华李松林张雷王淼

Owner HENAN CHAOWEI POWER SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com