Preparation method of lead storage battery grid alloy

A lead-acid battery and grid technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low utilization rate of rare earth metals, high energy consumption of rare earth alloys, high impurity content, etc., and achieve high raw material utilization rate and low impurity content The effect of less and high process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

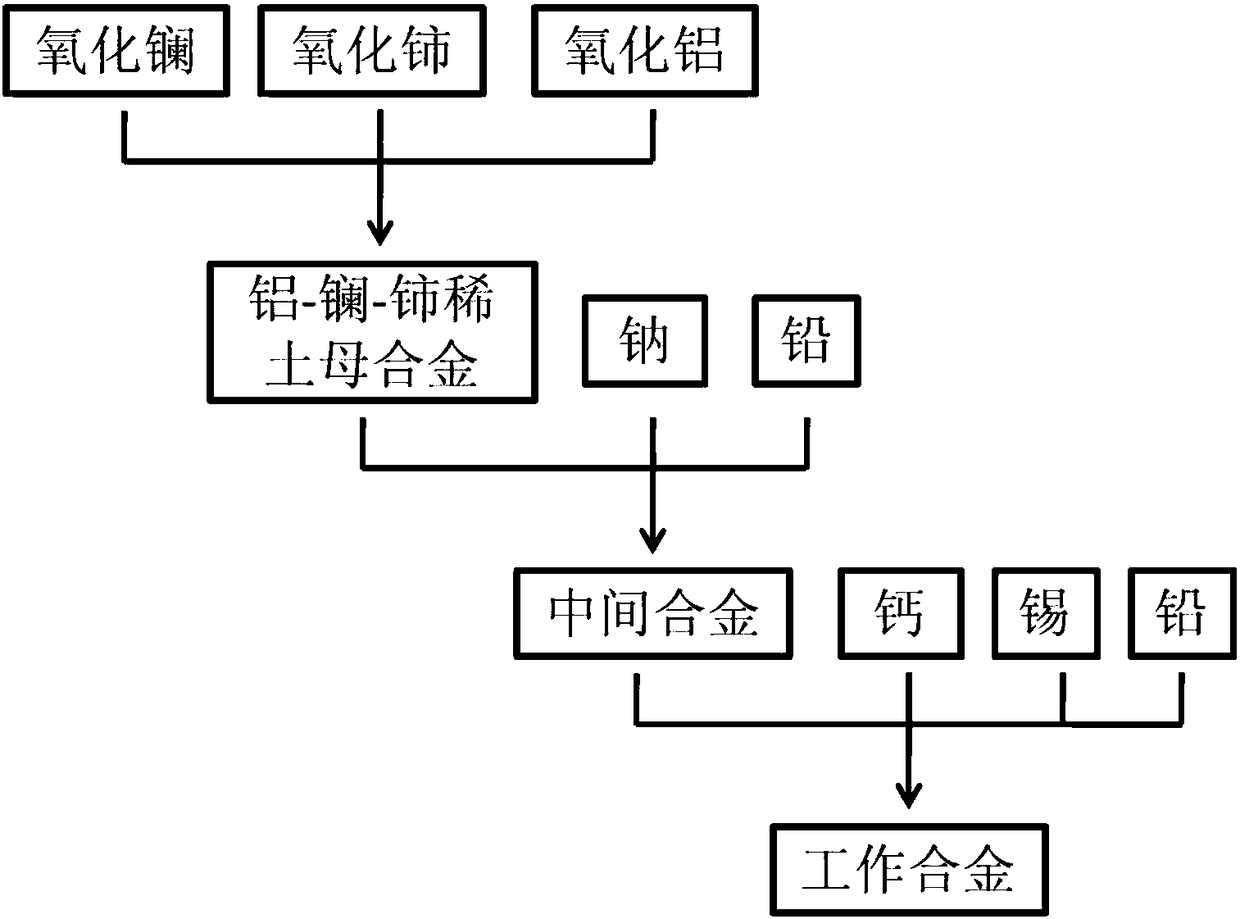

[0038] Aluminum-lanthanum-cerium rare earth master alloy was prepared by molten salt electrolysis.

[0039] The mass ratio of each component in the electrolyte system is LaF 3 : CeF 3 :LiF:BaF 2 =40:40:10:10; the mass ratio of the added raw materials is La 2 o 3 : CeO 2 :Al 2 o 3 =25:25:50. The current intensity of molten salt electrolysis is 2800A, and the anode current density is 1.0~1.2A / cm 2 , the cathode current density is 15~18A / cm 2, the electrolysis temperature is 880-910°C; the quality of the electrolyte in the electrolytic furnace is 100kg, and 5kg of raw materials are put into the electrolytic furnace to obtain 2.6kg of alloy. The ratio is 95.1%, and the composition of the aluminum-lanthanum-cerium rare earth master alloy is shown in Table 1, wherein Fe, Si, C, Cu, Ag, Sb, etc. are impurities, the same below.

[0040] Table 1 Analysis results of aluminum-lanthanum-cerium rare earth master alloy composition / %

[0041] La

Embodiment 2

[0043] Aluminum-lanthanum-cerium rare earth master alloy was prepared by molten salt electrolysis.

[0044] The mass ratio of each component in the electrolyte system is LaF 3 : CeF 3 :LiF:BaF 2 =30:30:20:20; the mass ratio of the added raw materials is La 2 o 3 : CeO 2 : Al 2 o 3 =40:30:30. The current intensity of molten salt electrolysis is 2700A, and the anode current density is 1.2~1.4A / cm 2 , the cathode current density is 18~20A / cm 2 , the electrolysis temperature is 920-950°C; the quality of the electrolyte in the electrolytic furnace is 250kg, and 5kg of raw materials are put into it to obtain an alloy of 3.2kg. 93.6%, the composition of the prepared aluminum-lanthanum-cerium rare earth master alloy is shown in Table 2.

[0045] Table 2 Analysis results of aluminum-lanthanum-cerium rare earth master alloy composition / %

[0046] La

Embodiment 3

[0048] Aluminum-lanthanum-cerium rare earth master alloy was prepared by molten salt electrolysis.

[0049] The mass ratio of each component in the electrolyte system is LaF 3 : CeF 3 :LiF:BaF 2 =40:40:10:10; the mass ratio of added raw materials is La 2 o 3 : CeO 2 : Al 2 o 3 =15:15:70. The current intensity of molten salt electrolysis is 2600A, and the anode current density is 1.3~1.5A / cm 2 , the cathode current density is 17~20A / cm 2 , the electrolysis temperature is 850-880°C; the quality of the electrolyte in the electrolytic furnace is 50kg, and 5kg of raw materials are put into it to obtain an alloy of 2.1kg. The content of lanthanum in the alloy is 28.4%, and the content of cerium is 27.3%. 92.5%, the composition of the prepared aluminum-lanthanum-cerium rare earth master alloy is shown in Table 3.

[0050] Table 3 Al-lanthanum-cerium rare earth master alloy composition analysis results / %

[0051] La

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com