Positive plate grid alloy for lead-acid storage battery

A lead-acid battery, positive plate technology, applied in the direction of electrode carrier/current collector, etc., to reduce fracture, prevent capacity decay, and reduce water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 AC impedance research of rare earth elements on lead oxide film

[0023] Using AC voltammetry (ACV) to conduct AC impedance research on the lead oxide film formed by adding 0.1% of 8 kinds of rare earth elements to the test electrode of lead, calcium and tin at 0.9V, the experimental results are shown in Table 1:

[0024] Table 1

[0025] rare earth element

[0026] It can be known from the above that various rare earth elements reduce the impedance of the lead oxide film to varying degrees. Among them, the four elements of praseodymium (Pr), terbium (Tb), samarium (Sm) and gadolinium (Gd) decreased most significantly.

Embodiment 2

[0027] Example 2 Research on Corrosion Rate of Rare Earth Elements on Electrode

[0028] Cyclic voltammetry (CV) was used to study the corrosion rate of the test electrode with 0.1% of lead-calcium-tin and 8 kinds of rare earth elements. The experimental results are shown in Table 2:

[0029] Table 2

[0030] rare earth element

[0031] It can be seen from the above that various rare earth elements have different effects on corrosion resistance. Among them, cerium (Ce), samarium (Sm) and ytterbium (Yb) can improve the corrosion resistance of the substrate, and ytterbium (Yb) has the best effect. On the contrary, lanthanum (La), praseodymium (Pr), neodymium (Nd), gadolinium (Gd) and terbium (Tb) reduce the corrosion resistance of the substrate, among which praseodymium (Pr) and neodymium (Nd) have the worst effect.

Embodiment 3

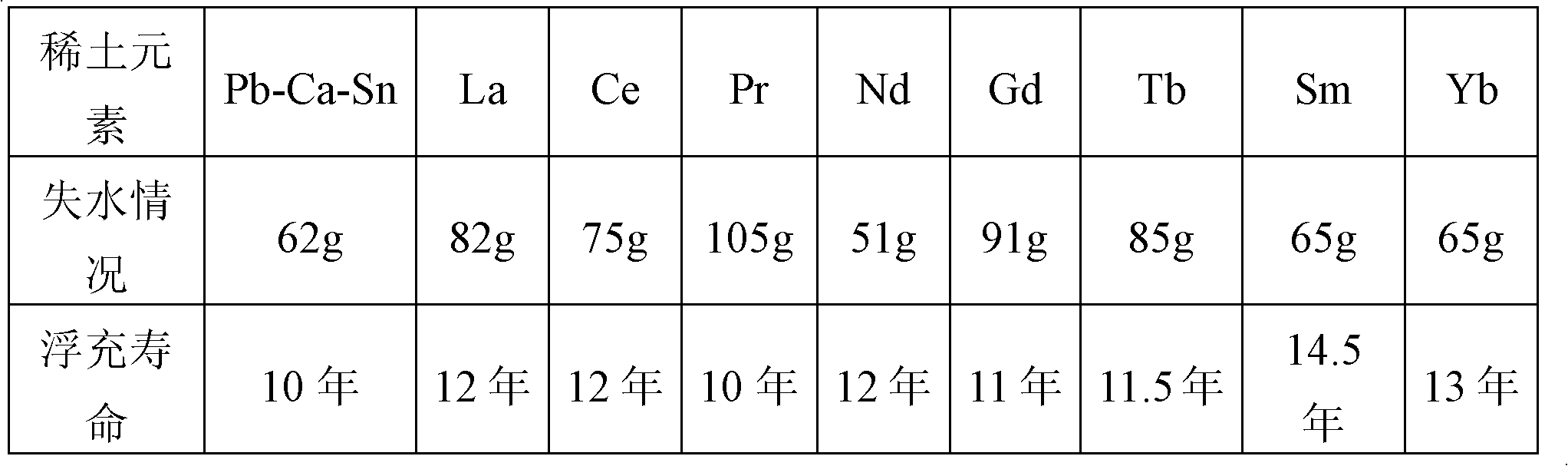

[0032] Example 3 Research on the Influence of Rare Earth Elements on Battery Float Charge Life

[0033] The alloy (a large amount of lead, calcium 0.08% tin 0.6% rare earth elements 0.05%) is cast into a positive grid with a thickness of 4.0 mm. After coating the positive active material, assemble it into a GMF2-200 backup battery for telecommunications, and carry out a high-temperature accelerated float charge life test according to the Ministry of Information Industry standard (YD / T799-2). The water loss of the battery (after 4 months of high temperature float charge) and float charge life (equivalent to normal temperature 25°C) are shown in Table 3:

[0034] table 3

[0035]

[0036] It can be seen from the above that the addition of rare earth elements can improve the float charge life of the battery. However, the result of prolonging the life of the battery is not directly proportional to the corrosion resistance effect of the rare earth on the alloy and the reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com