Heat treatment process of storage battery grid

A battery and grid technology, applied in lead-acid battery electrodes and other directions, can solve the problems of short life, poor battery consistency, unstable grid physical and chemical properties, etc., to improve the crystal phase structure, reduce ohmic internal resistance, improve Effects of consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

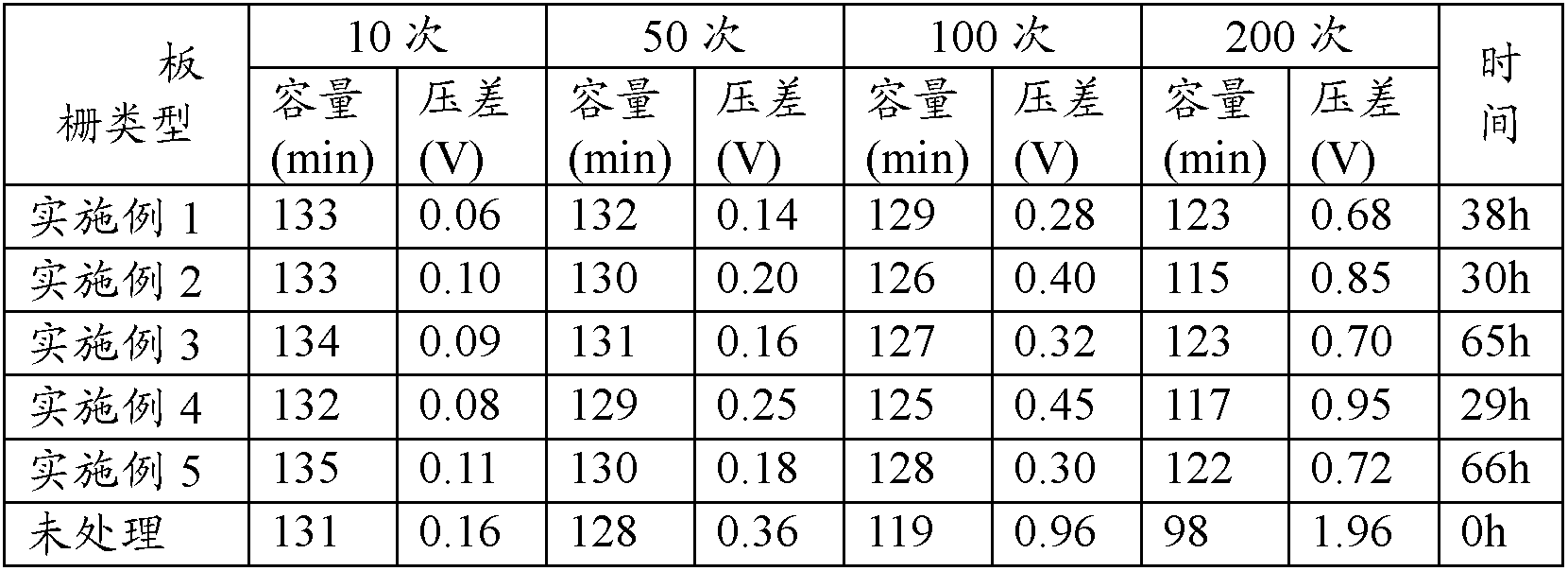

Examples

Embodiment 1

[0012] In the first stage, the newly cast grid is put into the curing room, and CO is introduced into the curing room 2 , so that the CO in the curing chamber 2 The volume concentration reaches 13%, and then steam is introduced to heat and humidify, so that the temperature in the curing room reaches 70°C and the humidity reaches 98%, and lasts for 24 hours.

[0013] In the second stage, the grid is transferred to the drying room. The temperature in the drying room is 85°C, stored for 4 hours, cooled naturally, and stored in a ventilated environment at room temperature for 10 hours before coating.

Embodiment 2

[0015] In the first stage, the newly cast grid is put into the curing room, and CO is introduced into the curing room 2 , so that the CO in the curing chamber 2 The volume concentration reaches 15%, and then steam is introduced to heat and humidify, so that the temperature in the curing room reaches 65°C and the humidity reaches 99%, and lasts for 12 hours.

[0016] In the second stage, the grid is transferred to the drying room. The temperature in the drying room is 80°C, stored for 6 hours, cooled naturally, and stored in a ventilated environment at room temperature for 12 hours before coating.

Embodiment 3

[0018] In the first stage, the newly cast grid is put into the curing room, and CO is introduced into the curing room 2 , so that the CO in the curing chamber 2 The volume concentration reaches 18%, and then the steam is heated and humidified, so that the temperature in the curing room reaches 60°C and the humidity reaches 99%, and lasts for 48 hours.

[0019] In the second stage, the grid is transferred to the drying room. The temperature in the drying room is 90°C, stored for 2 hours, cooled naturally, and stored in a ventilated environment at room temperature for 15 hours for coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com