Production process of storage battery positive plate

A production process and positive plate technology, which is applied in the production process field of battery positive plates, to achieve the effects of inhibiting sulfation of negative electrodes, improving corrosion resistance, and uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

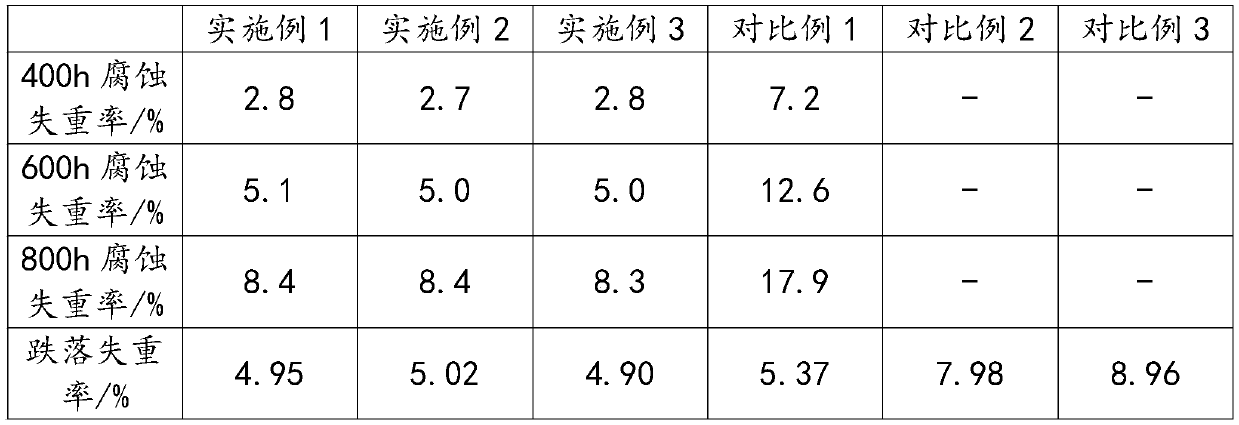

Examples

preparation example Construction

[0027] The first step, preparation of alloy grid: Pb-Ca-Sn-Al alloy and alloy additives are gravity casted into lead rod alloy at 500°C, and then the lead rod alloy is made into grid at 500°C;

[0028] Wherein, the alloy additive is TaC (thallium carbide), and the addition amount of the alloy additive is 0.5% of the alloy mass;

[0029] When Pb-Ca-Sn-Al alloy forms grains, due to the precipitation of Ca, it will form unevenly distributed intermetallic compounds, which hinder the growth of grains, resulting in uneven grain distribution and large size differences. After the addition of TaC, TaC can play the role of refining the grain, so that the grain size of the alloy is reduced and the grain distribution is uniform, the microstructure of the alloy is improved, and the corrosion resistance of the grid alloy can be effectively improved;

[0030] The second step is to prepare the positive lead paste, and apply the positive lead paste evenly on the surface of the grid by a coatin...

Embodiment 1

[0044] A production process for a storage battery positive plate, comprising the steps of:

[0045] The first step, preparation of alloy grid: Pb-Ca-Sn-Al alloy and alloy additives are gravity casted into lead rod alloy at 500°C, and then the lead rod alloy is made into grid at 500°C;

[0046] The second step is to prepare the positive lead paste, and apply the positive lead paste evenly on the surface of the grid by a coating machine to obtain a wet grid;

[0047] Positive lead paste is made of the following raw materials by weight: 90 parts of lead powder, 8 parts of sulfuric acid aqueous solution, 14 parts of deionized water, 0.5 part of sodium perborate, 0.15 part of graphene;

[0048] The third step, wet grid curing: in the first stage, the wet grid is cured at a temperature of 48°C and a humidity of 99% for 45 hours; in the second stage, the cured grid in the first stage is cured at a temperature of 84°C without Dry under humidified conditions for 30 hours;

[0049] Th...

Embodiment 2

[0051] A production process for a storage battery positive plate, comprising the steps of:

[0052] The first step, preparation of alloy grid: Pb-Ca-Sn-Al alloy and alloy additives are gravity casted into lead rod alloy at 500°C, and then the lead rod alloy is made into grid at 500°C;

[0053] The second step is to prepare the positive lead paste, and apply the positive lead paste evenly on the surface of the grid by a coating machine to obtain a wet grid;

[0054] Positive lead paste is made of the following raw materials by weight: 95 parts of lead powder, 10 parts of sulfuric acid aqueous solution, 16 parts of deionized water, 0.8 part of sodium perborate, 0.18 part of graphene;

[0055] The third step, wet grid curing: in the first stage, the wet grid is cured at a temperature of 49°C and a humidity of 100% for 44 hours; in the second stage, the cured grid in the first stage is cured at a temperature of 85°C without Dry under humidified conditions for 29 hours;

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com