Lead-acid battery electrolyte

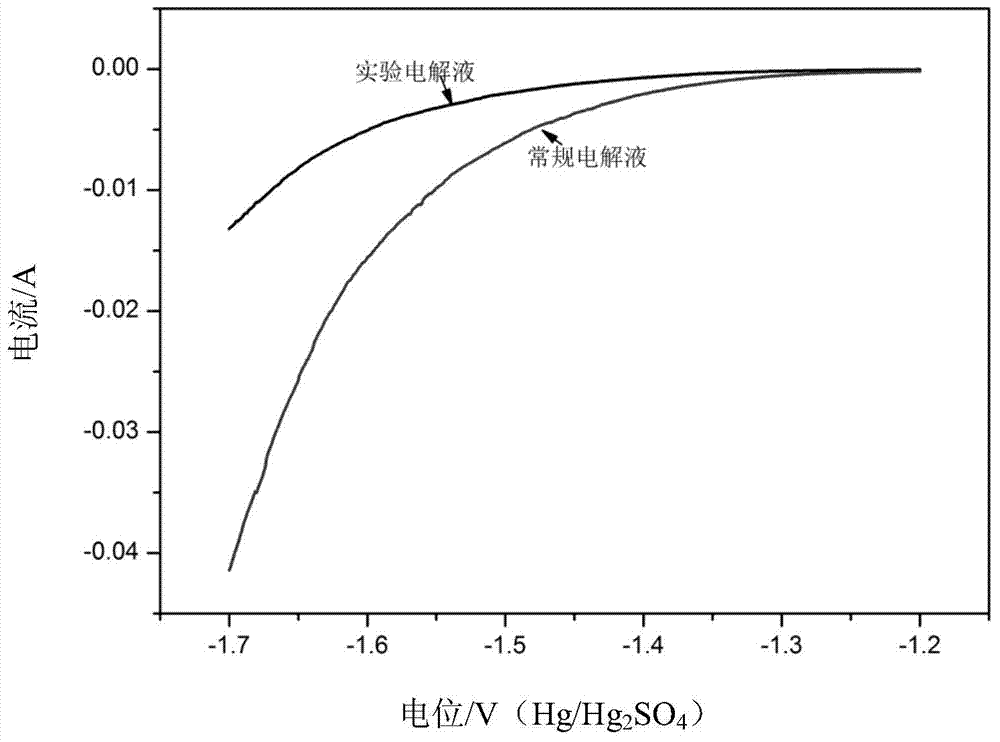

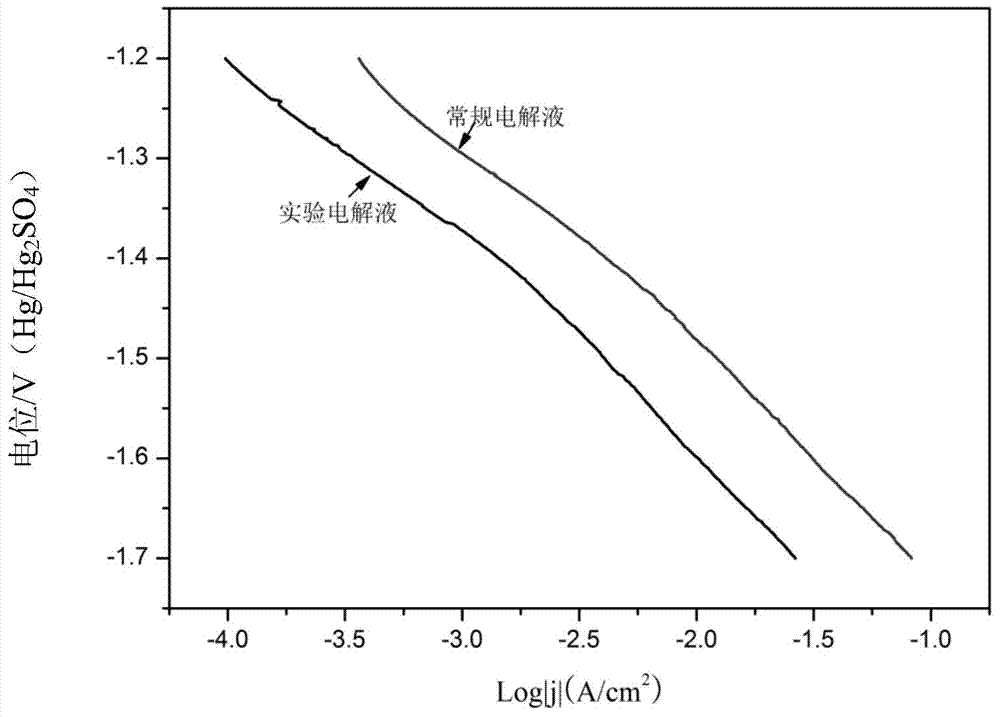

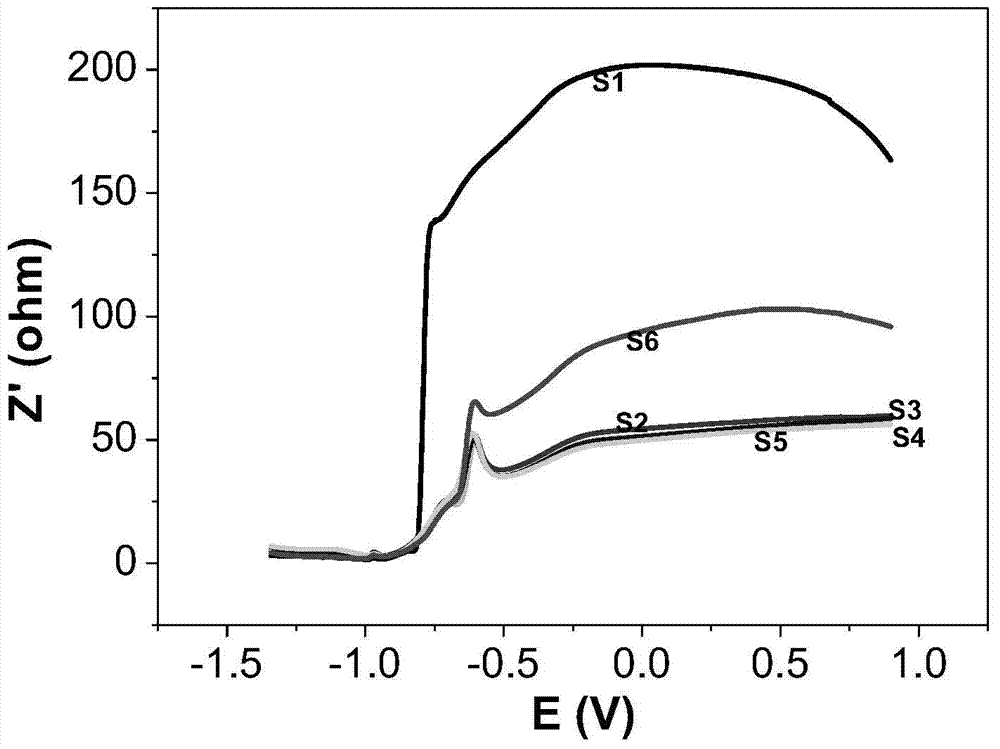

A lead-acid battery and electrolyte technology, applied in lead-acid batteries and other directions, can solve the problems of the battery charging performance to be improved, the composition is complex, the preparation method is cumbersome, etc., and the water loss is reduced, the addition method is simple, and the environment is pollution-free.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 lead-acid accumulator electrolyte

[0031] Get 0.134g of 3,5-diaminobenzoic acid and add in 1L sulfuric acid aqueous solution (density is 1.34g / cm3), obtain lead-acid battery electrolyte, the concentration of 3,5-diaminobenzoic acid in this lead-acid battery electrolyte 100ppm.

Embodiment 2

[0032] Preparation of embodiment 2 lead-acid battery electrolyte additive and lead-acid battery electrolyte

[0033] Get 0.67g of 3,5-diaminobenzoic acid and 0.074g of bismuth oxide and mix to obtain the electrolyte additive for lead-acid battery.

[0034] Add the obtained lead-acid battery electrolyte additive to 1L sulfuric acid aqueous solution (density is 1.34g / cm 3 ), the lead-acid battery electrolyte was obtained, the concentration of 3,5-diaminobenzoic acid in the lead-acid battery electrolyte was 500ppm, and the concentration of bismuth ions was 50ppm.

Embodiment 3

[0035] Preparation of embodiment 3 lead-acid battery electrolyte additive and lead-acid battery electrolyte

[0036] Get 0.938g of 3,5-diaminobenzoic acid and 0.104g of bismuth oxide and mix them to obtain the electrolyte additive for lead-acid batteries.

[0037] Add the obtained lead-acid battery electrolyte additive to 1L of sulfuric acid aqueous solution (density is 1.34g / cm 3 ), the lead-acid battery electrolyte was obtained, the concentration of 3,5-diaminobenzoic acid in the lead-acid battery electrolyte was 700ppm, and the concentration of bismuth ions was 70ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com