Run-flat tire

A zero-pressure tire and tire technology, applied in the field of sidewall-reinforced zero-pressure tires, can solve problems such as deterioration of driving stability, achieve the effects of improving riding comfort, improving durability, and avoiding local stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

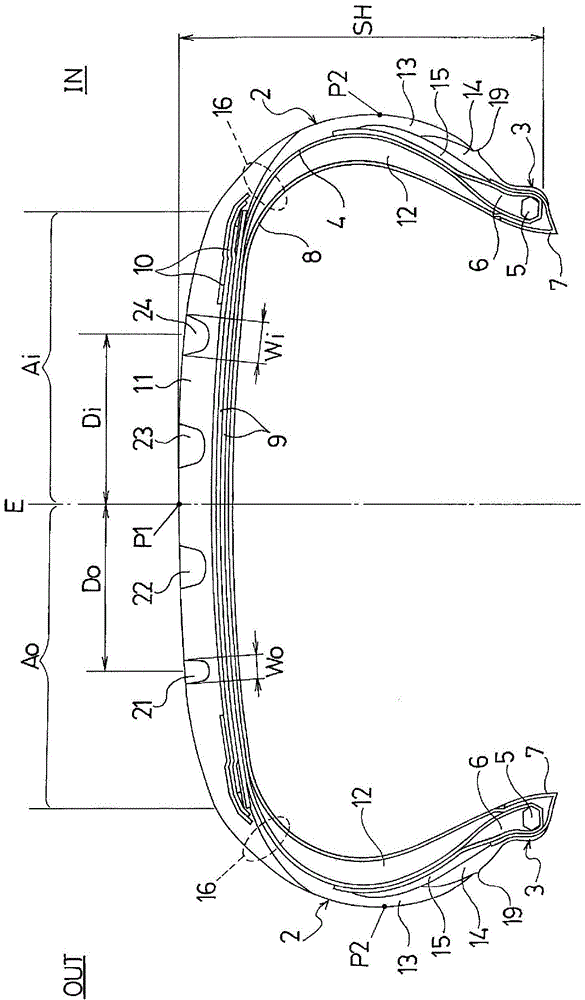

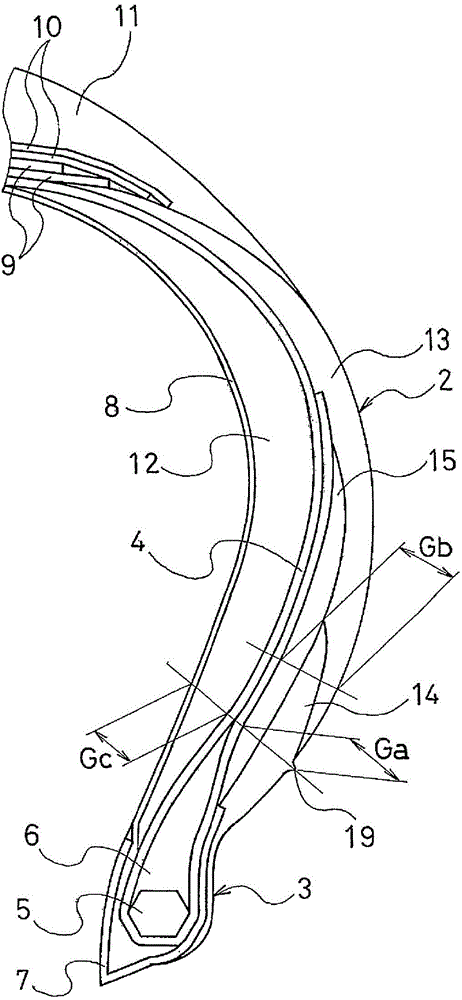

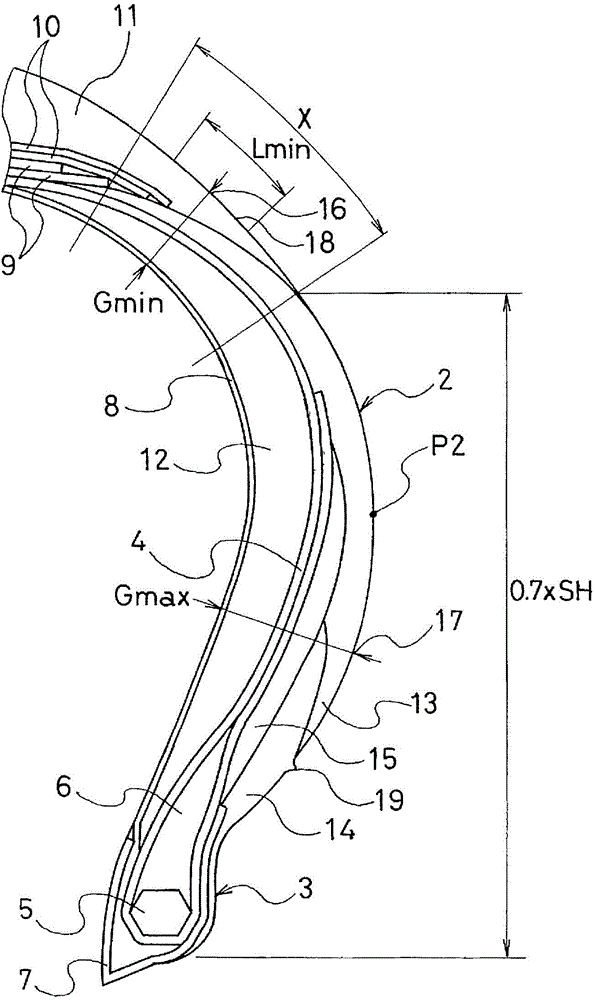

[0056] The tires of Conventional Example, Comparative Examples 1 to 6, and Examples 1 to 4 were produced. The tire size was 235 / 50R18, and one layer of carcass was arranged between a pair of bead parts. The periphery of the bead core is rolled up from the inner side of the tire to the outer side, a bead filler is arranged on the outer peripheral side of each bead core in the bead portion, and two belt layers are arranged on the outer peripheral side of the carcass layer of the tread portion. A cover layer is arranged on the outer peripheral side, a side wall reinforcement layer with a crescent-shaped cross-section is arranged between the carcass layer of the side wall portion and the inner liner layer, an additional reinforcement layer is buried outside the carcass layer, and the position when it is installed on the vehicle is specified Orientation, wherein the relationship between the distance Do and the rim width Wr from the center position of the circumferential main groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com