Vibrating mirror element and manufacturing method for same

A manufacturing method and mirror technology, applied to electrical components, microstructure devices composed of deformable components, optical components, etc., can solve the problems of low rigidity of the region, easy to produce bending deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

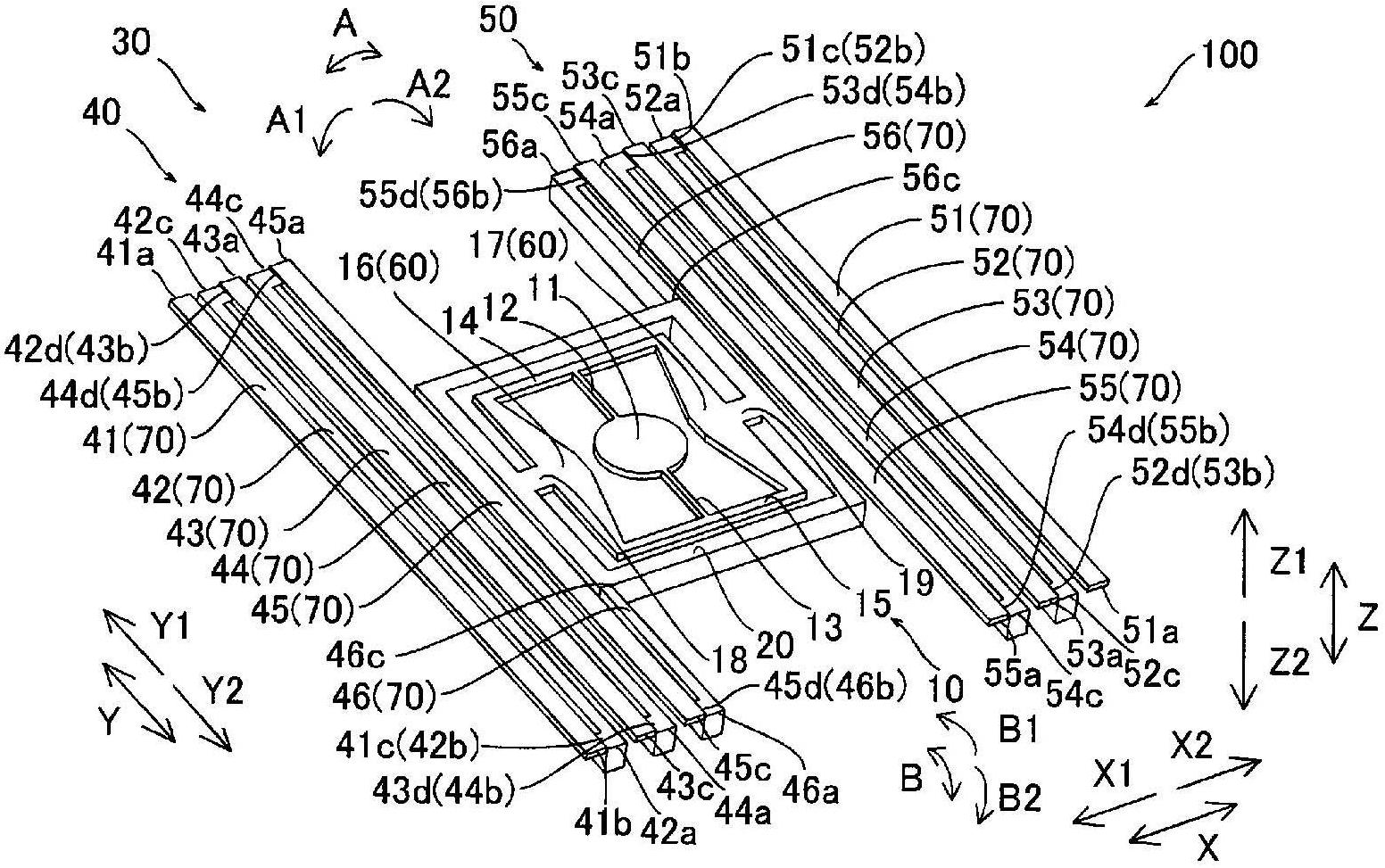

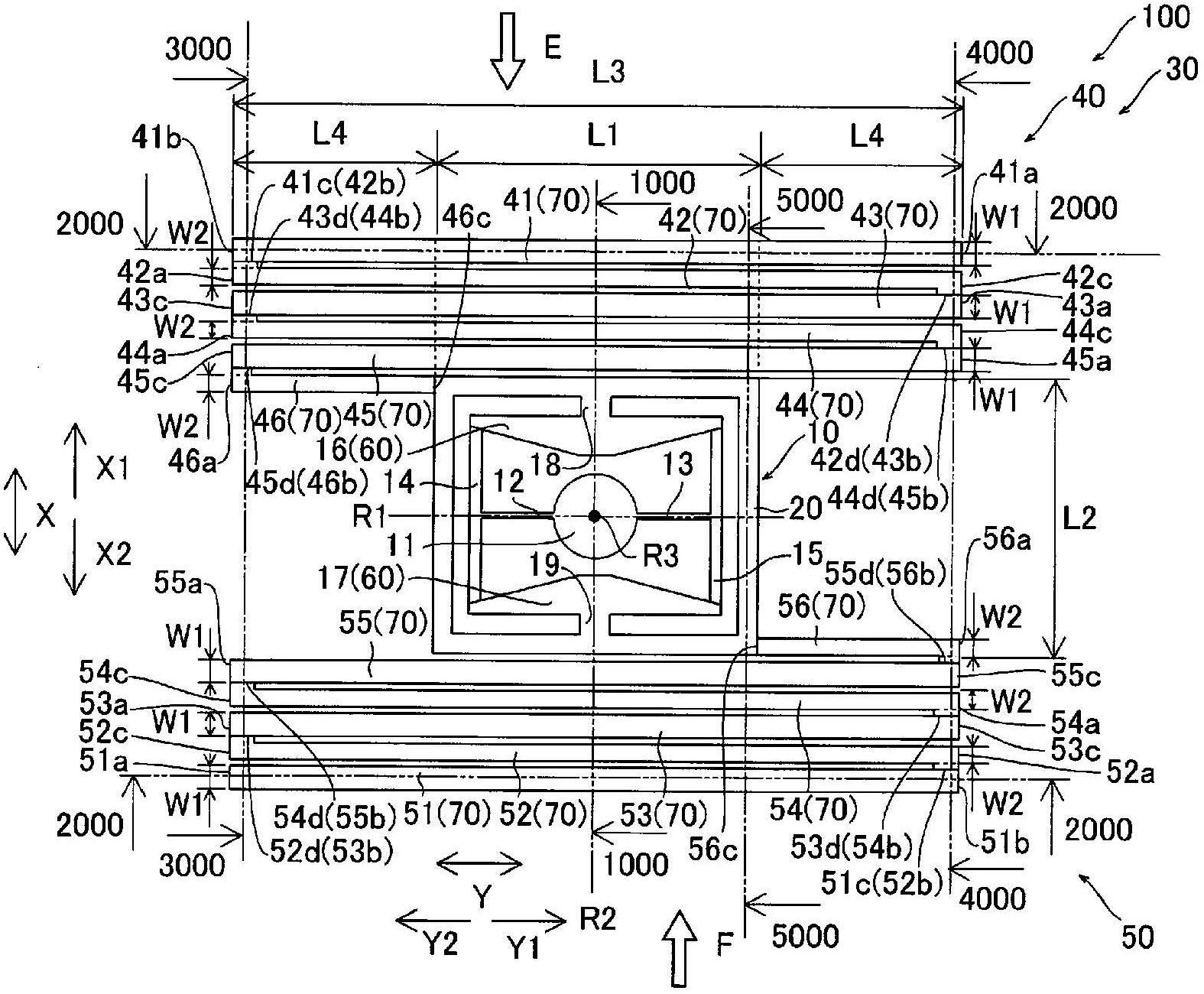

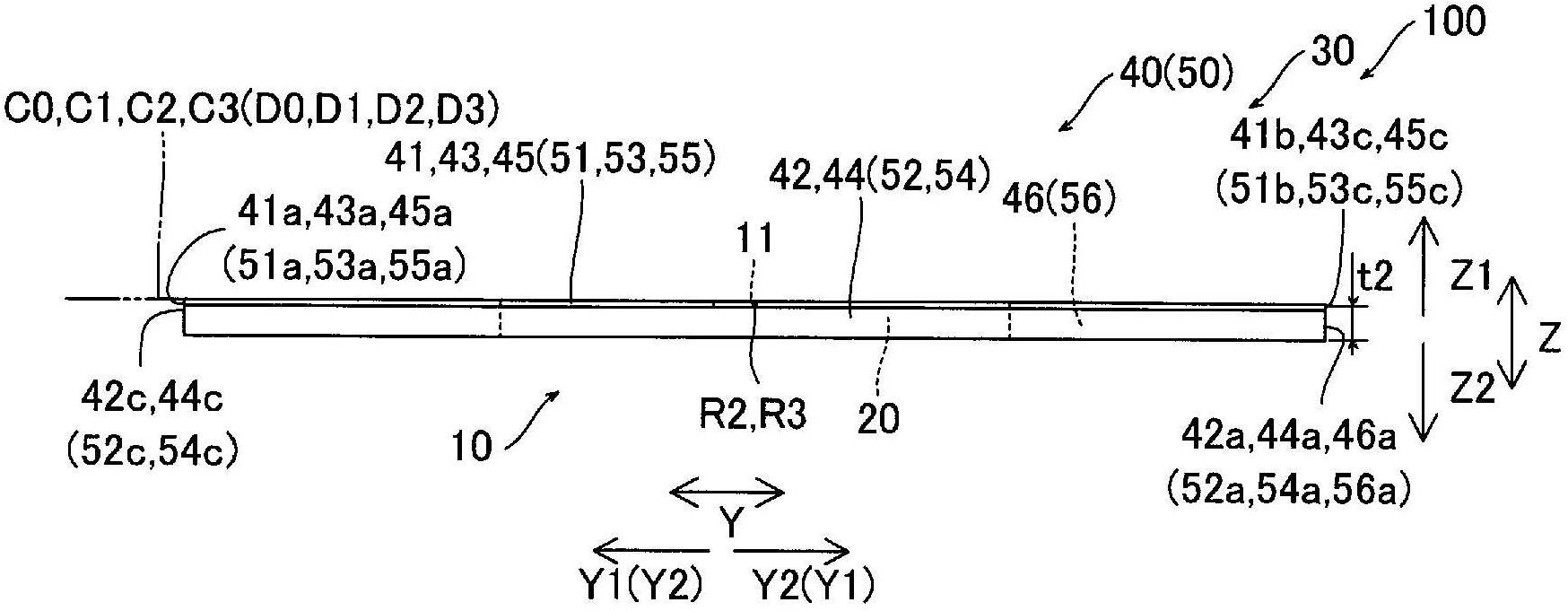

[0056] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

[0057] First, refer to Figure 1 to Figure 10 , the structure of the vibrating mirror element 100 according to one embodiment of the present invention will be described.

[0058] Such as Figure 1 to Figure 3 As shown, the vibrating mirror element 100 according to one embodiment of the present invention has: an X-direction light scanning unit 10 that scans with light in the X direction using a mirror 11 described later; a Y-direction light scanning unit 30 that uses The mirror 11 scans with light in the Y direction perpendicular to the X direction. In addition, if Figure 4 to Figure 8 As shown, the X-direction optical scanning unit 10 and the Y-direction optical scanning unit 30 are integrally formed on a general-purpose upper Si substrate 1 having a thickness t1 of about 0.1 mm. In addition, the X direction light scanning part 10 is an example of the "mir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com