Wall panel

A technology of wall panels and folding panels, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of high transmission efficiency, high transportation costs, decreased stress transmission efficiency, and increased cost of wall panels, achieving reliable screw fixing and preventing Excellent resistance to deterioration and deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Each embodiment of the present invention will be described below based on the drawings.

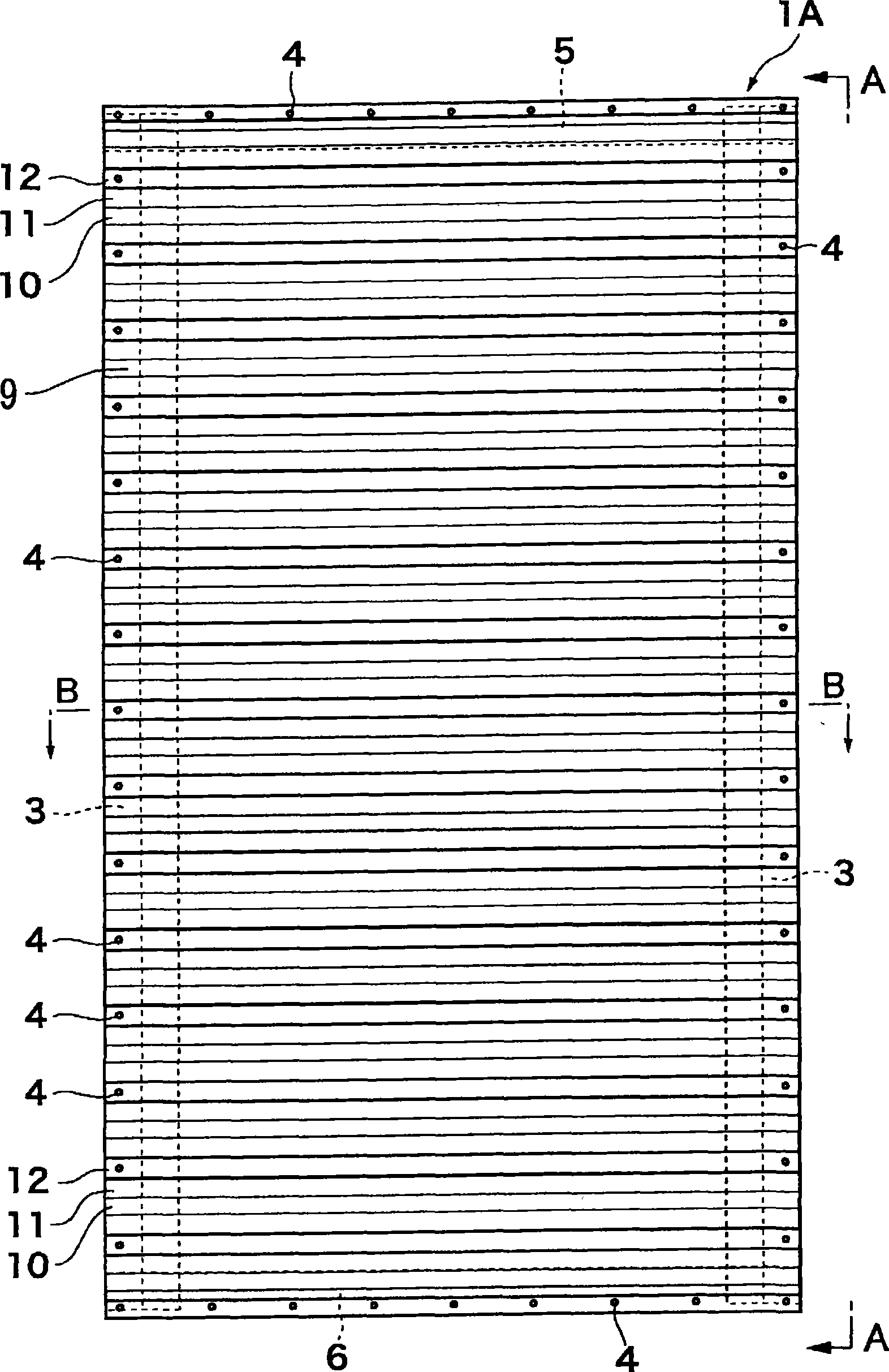

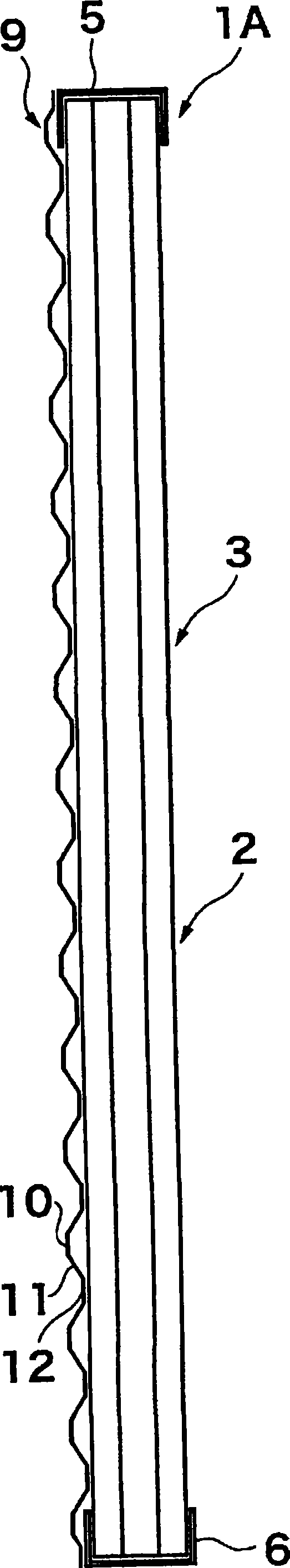

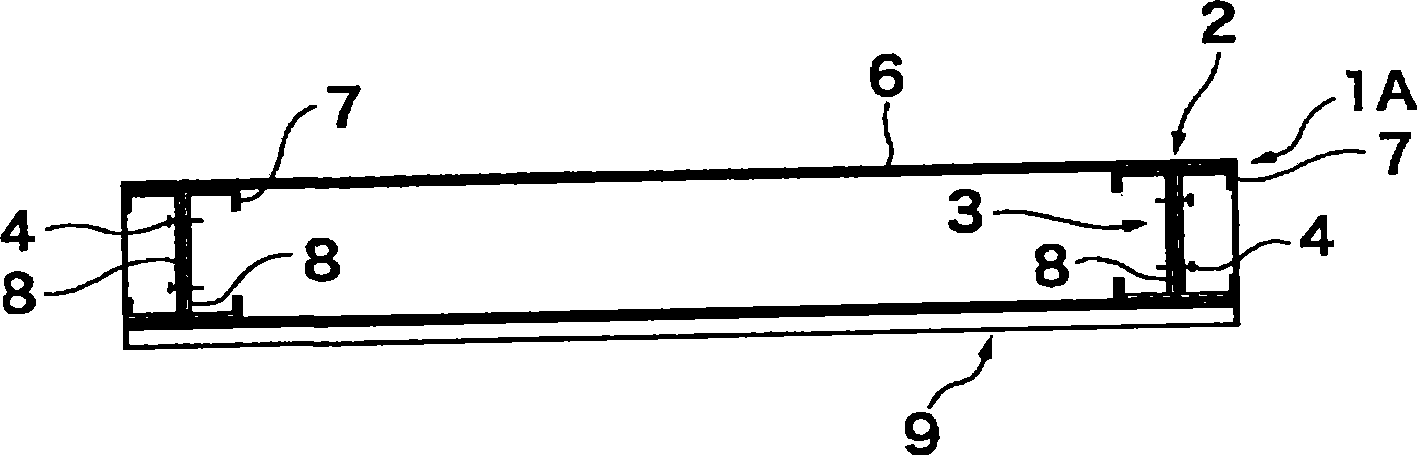

[0102] First, the frame body 2 used for wall panel 1A, 1B, 1C of each embodiment is demonstrated. Such as Figure 5A ~ Figure 5C As shown, the rectangular frame body 2 is composed of a pair of vertical frame members 3 arranged opposite to each other at intervals, arranged astride the upper ends of these vertical frame members 3, and fastening members 4 are fixed by screws such as self-tapping screws. The joined upper horizontal frame members 5 and the lower horizontal frame members 6 arranged across the lower ends of these vertical frame members 3 and joined by screw fixing fixtures 4 such as self-tapping screws are configured. No reinforcement bars are provided between the vertical frame members 3 . In each embodiment, the folded plates described later exert the same function as when the reinforcement bars are provided, thereby preventing the vertical frame members 3 from twistin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com