Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layers, tire parts, wheels, etc. of pneumatic tires to prevent the phenomenon of folding in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

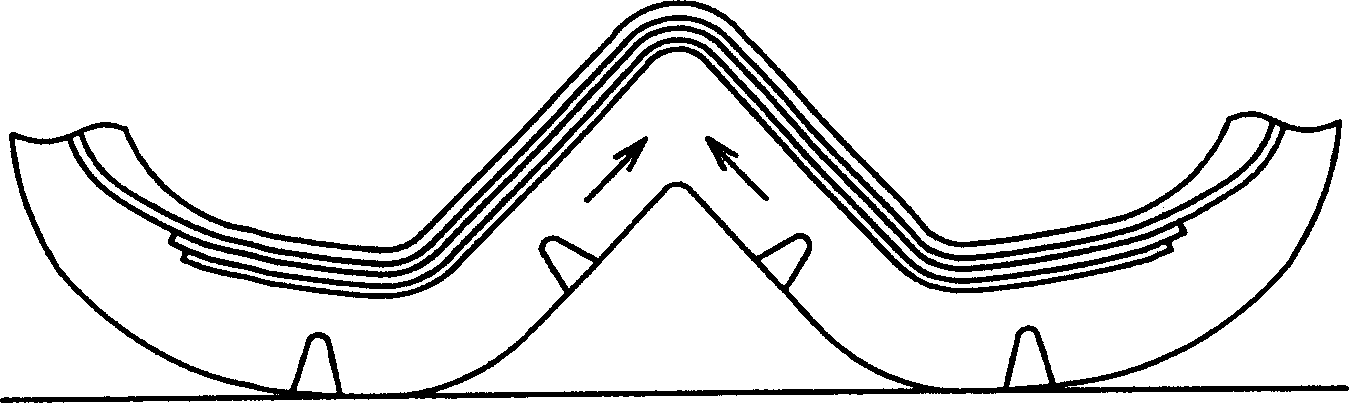

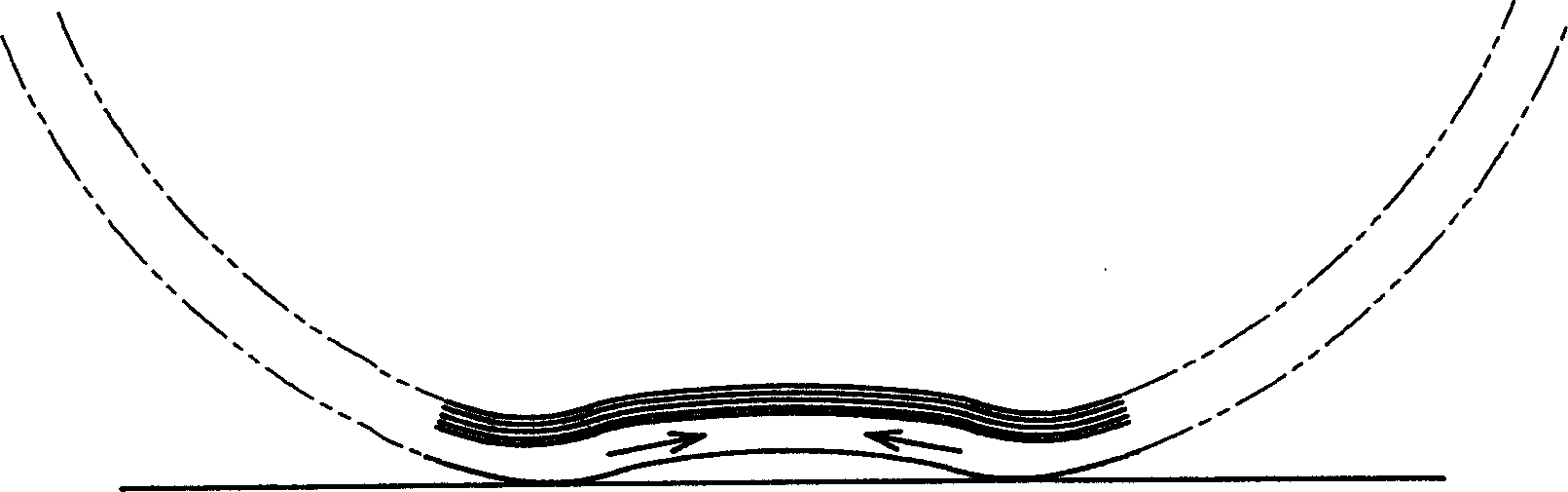

Method used

Image

Examples

Embodiment

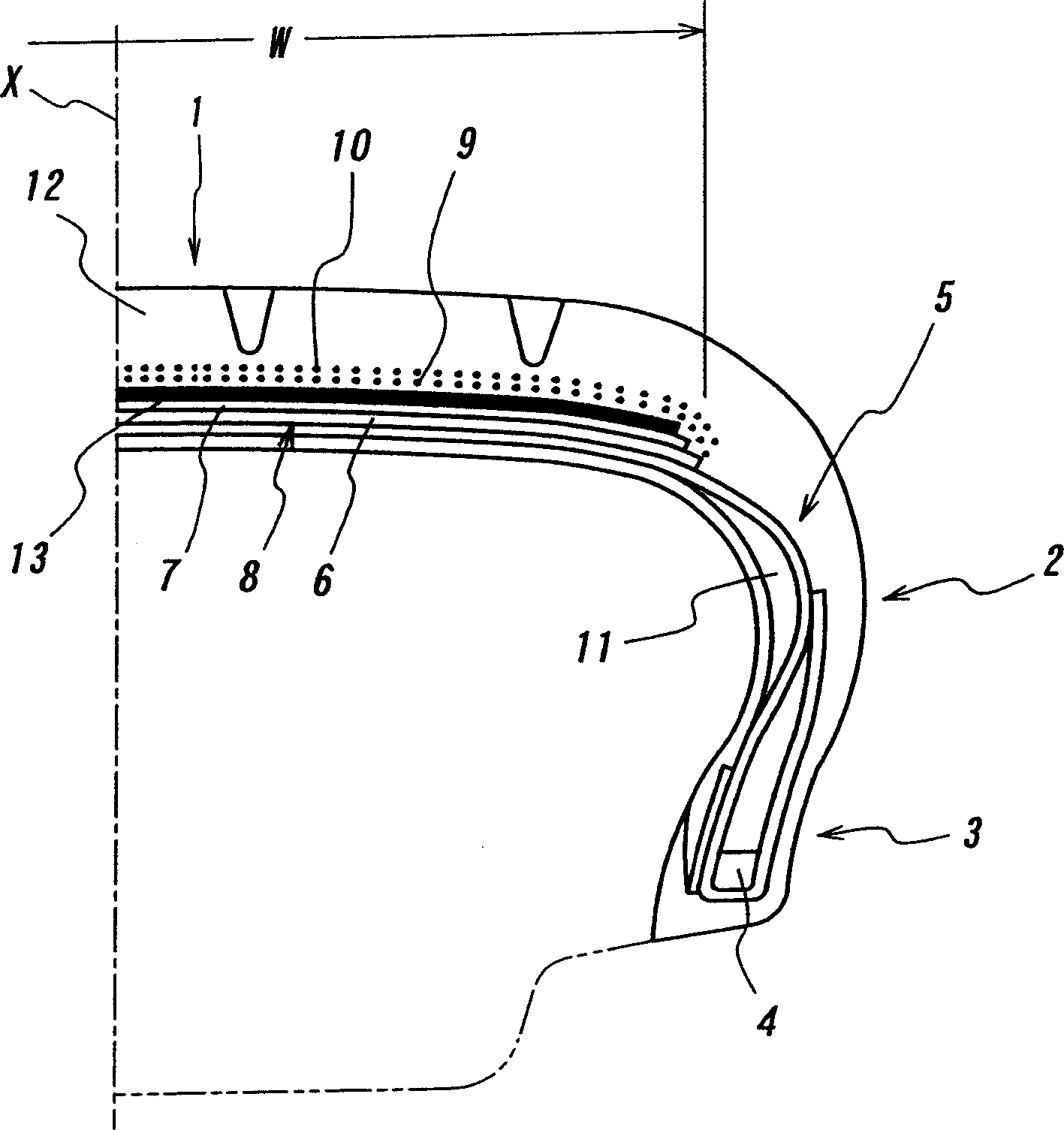

[0043] The size of each tire in the embodiment and the comparative example is 245 / 40R18, and has the structure shown in Figure 2, and the size is shown in Table 1, wherein the largest rubber reinforcement layer made of low-damage, high-rigidity rubber is used The thickness is 8mm, the two layers of the hat are made of nylon fiber rope, the width of the inner belt layer is 200mm, the width of the outer belt layer is 190mm, and the width of the additional belt layer is 180mm, they are installed in a rim of 18×8JJ , inflated to an air pressure of 230kPa or 0kPa. As for the driving stability on icy roads, no matter whether it has run to 200km or not, when the internal pressure is reduced, the lift of the tire surface and the durability of running smoothly can be achieved without problems. When the internal pressure of the tire is 0kPa and the load is 4.81 When kN and speed are 89km / h, the test results are shown in Table 1.

[0044] In Table 1, the elastic volume coefficient of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com