Strengthening treatment method for glass tube in on-line production process

A production process and strengthening treatment technology, applied in the field of glass material manufacturing, can solve the problems of not conforming to the basic concept, increasing the quality of devices or devices, consuming glass raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

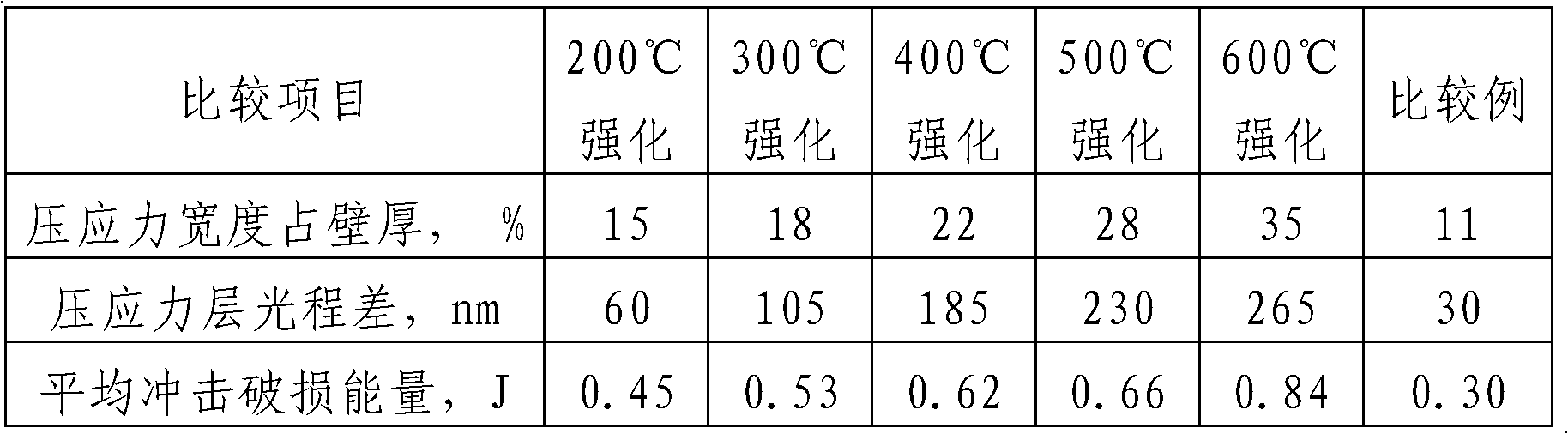

Embodiment 1

[0013] Taking the medical glass tube produced by Dana method as an example, the glass material is low borosilicate glass, the size specification is 15.8mm in outer diameter, and the wall thickness is 1.0mm. When the temperature is 600°C, the strengthening treatment of glass tubes in the online production process is carried out, using an ultra-micro atomizer, the atomized particles are less than 5 microns, the strengthening treatment medium is vinyltriethoxysilane aqueous solution, the solid content is 15wt%, and the spraying dosage is 15L / hour, the surface stress value and impact damage energy of the glass tube after strengthening treatment, the comparative example is the glass tube without strengthening treatment.

[0014] The width of the compressive stress area of the glass tube and the value of the compressive stress are measured by using an orthogonal polarizing microscope. A full-wave plate (565nm optical path difference) is inserted in the optical path of the microsco...

Embodiment 2

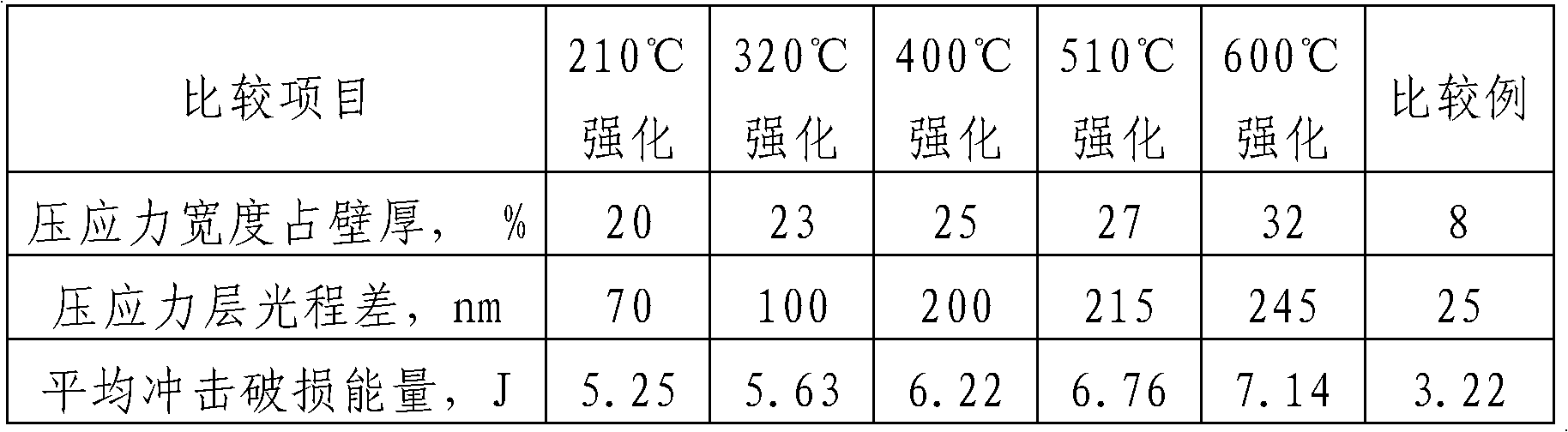

[0019] Taking the blank tube for solar heat collector produced by the maintenance method as an example, the glass material is high borosilicate glass, the size specification is 58mm in outer diameter, and the wall thickness is 1.8mm. At ℃ and 600℃, the strengthening treatment of glass tubes in the online production process is carried out, using an ultra-micro atomizer, the atomized particles are less than 5 microns, the strengthening treatment medium is diethyldichlorosilane aqueous solution, the solid content is 25wt%, and the amount of spraying 20L / hour, the surface stress value and impact damage energy of the glass tube after strengthening treatment, the comparative example is the glass tube without strengthening treatment.

[0020] The measurement and characterization method is the same as in Example 1, and the measured values are shown in Table 2.

[0021] Table 2 Comparison table of on-line strengthening treatment of blank tubes for high borosilicate solar collector tu...

Embodiment 3

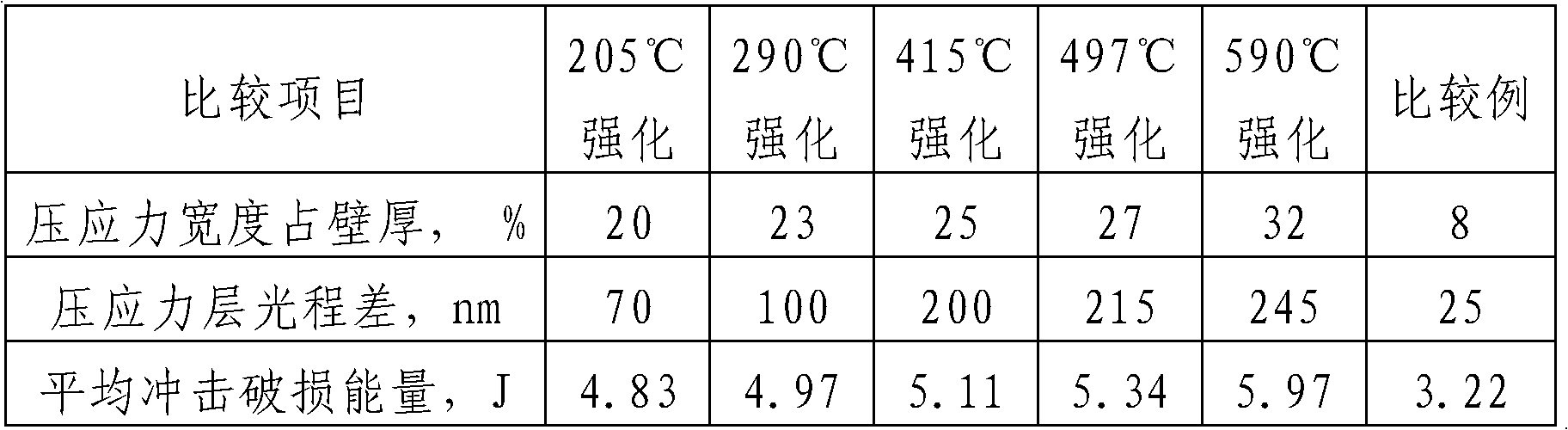

[0024] Taking the blank tube for solar heat collector produced by the maintenance method as an example, the glass material is high borosilicate glass, the size specification is 58mm in outer diameter, and the wall thickness is 1.8mm. ℃, 590 ℃, the strengthening treatment of glass tubes in the online production process, using ultra-micro atomizer, the atomized particles are less than 5 microns, the strengthening treatment medium is pure water, the spraying amount is 20L / hour, the surface stress of the glass tube after strengthening treatment Value and impact breakage energy, the comparative example is a glass tube that has not been strengthened.

[0025] The measurement and characterization method is the same as in Example 1, and the measured values are shown in Table 3.

[0026] Table 3 Comparison table of on-line strengthening treatment of blank tubes for high borosilicate solar collector tubes (pure water medium)

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com