Worm drive

A technology of worm drive and worm shaft, which is applied in hoisting devices, portable lifting devices, components with teeth, etc., and can solve problems such as increased expansion/contraction and difficulty in maintaining backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

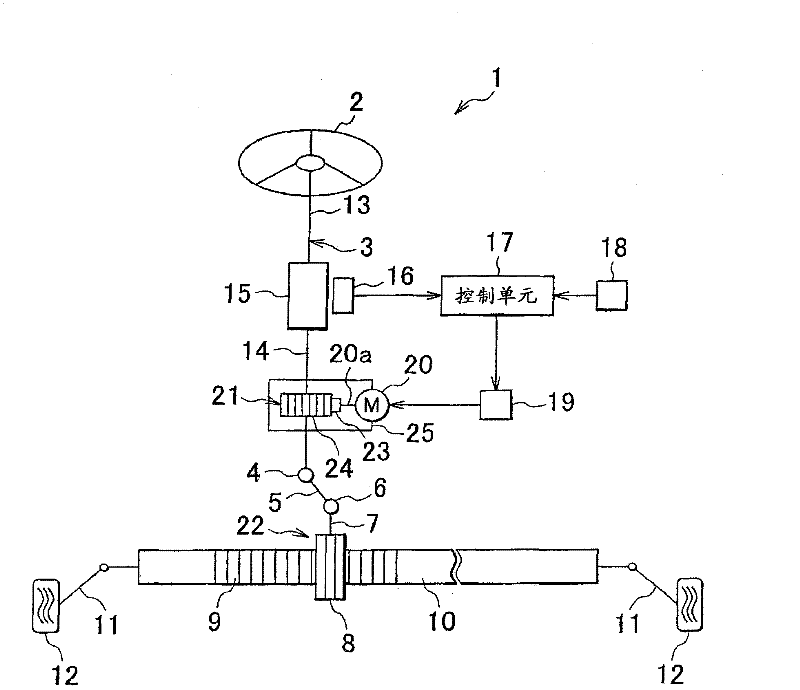

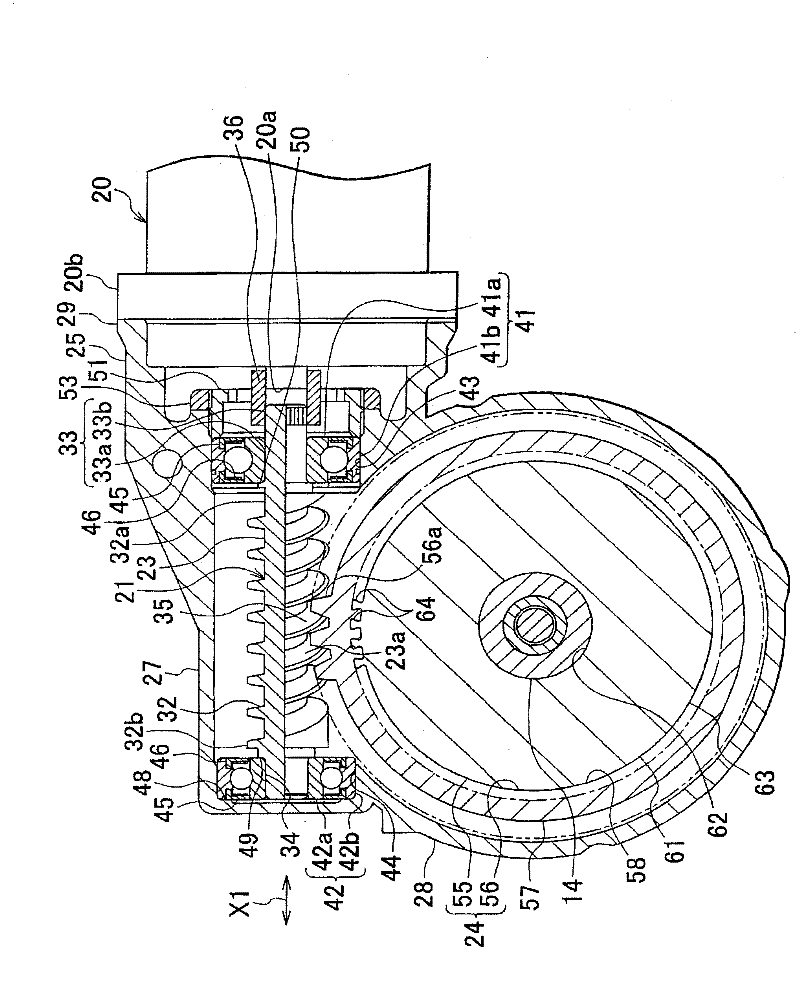

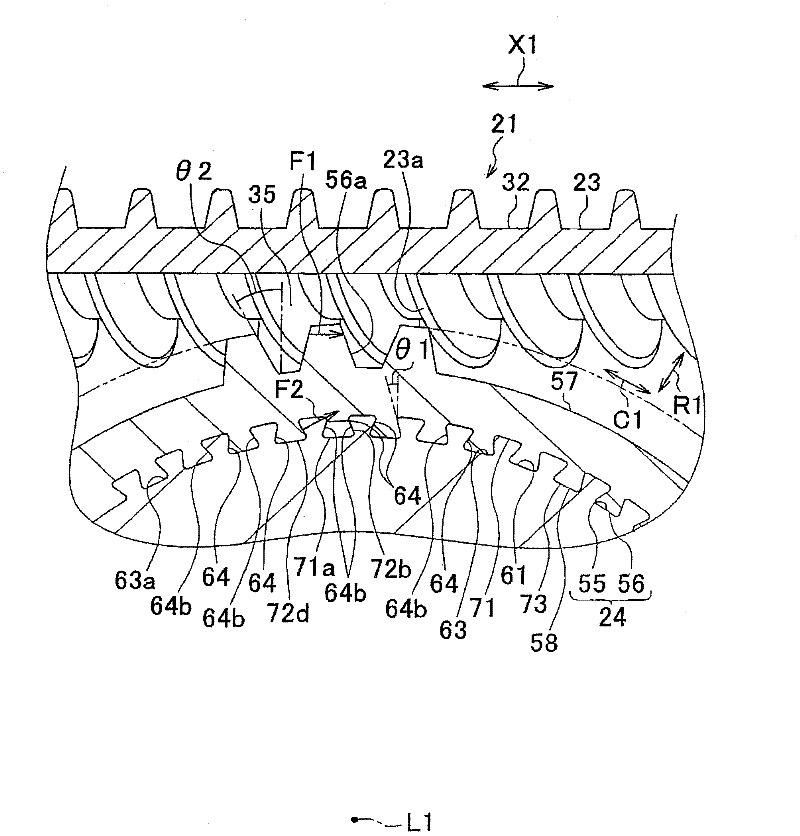

[0022] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a schematic diagram showing a schematic configuration of the electric power steering apparatus 1 according to the first embodiment of the present invention. see figure 1 , the electric power steering apparatus 1 has: a steering shaft 3 connected to a steering member 2 such as a steering wheel; an intermediate shaft 5 connected to the steering shaft 3 through a universal joint 4; a pinion shaft 7 connected to the intermediate shaft 5 through a universal joint 6 ; and the rack shaft 10 . The rack shaft 10 forms a rack 9 that meshes with a pinion 8 provided at the distal end of the pinion shaft 7 and extends in the left-right direction of the vehicle.

[0023] Rods 11 are connected to respective ends of the rack shaft 10, and each tie rod 11 is connected to a corresponding steering wheel 12 through a corresponding joint arm (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com