Rotor cage type elastic support

An elastically supported, squirrel-cage technology, applied in the direction of rigid brackets, bearing components, shafts and bearings of bearing components, can solve problems such as reduced sensitivity and accuracy, shortened life, machine structure or component damage, etc., to improve stability. durability and service life, suppressing bending deformation, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

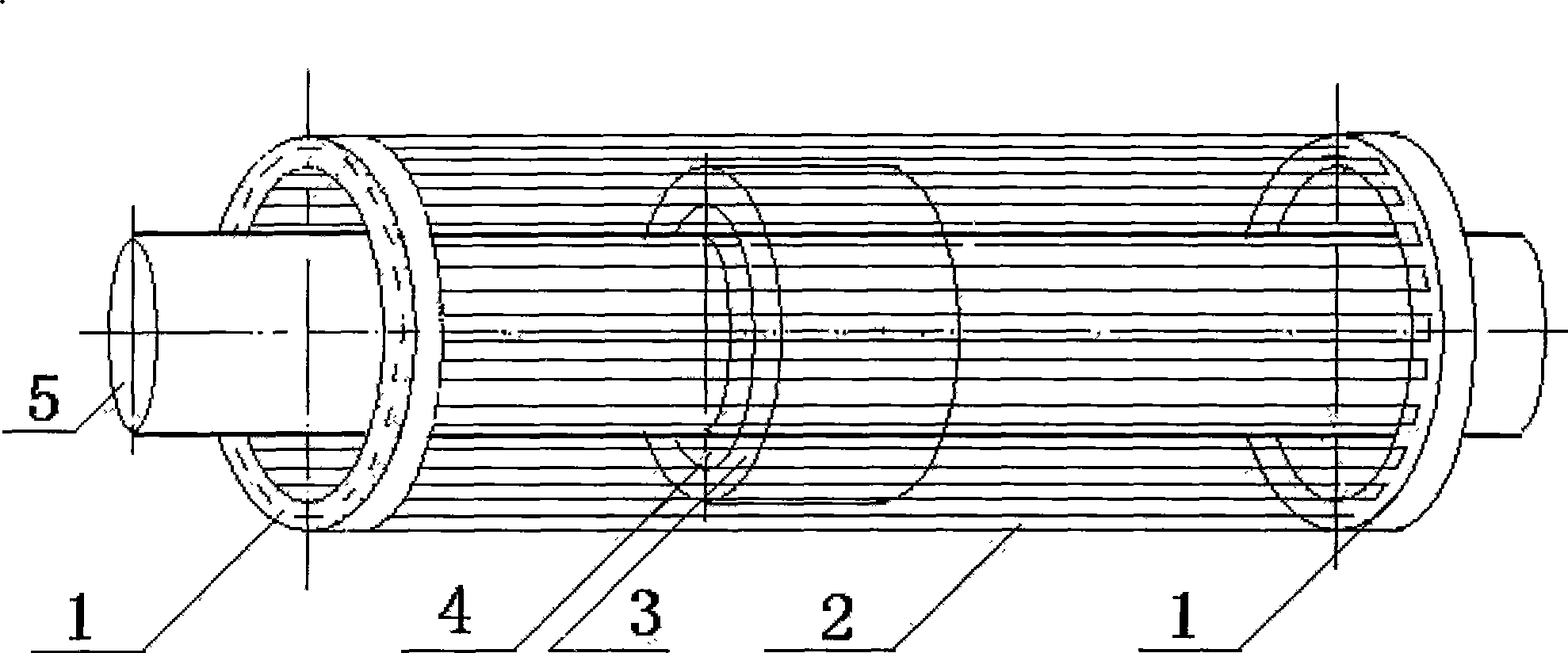

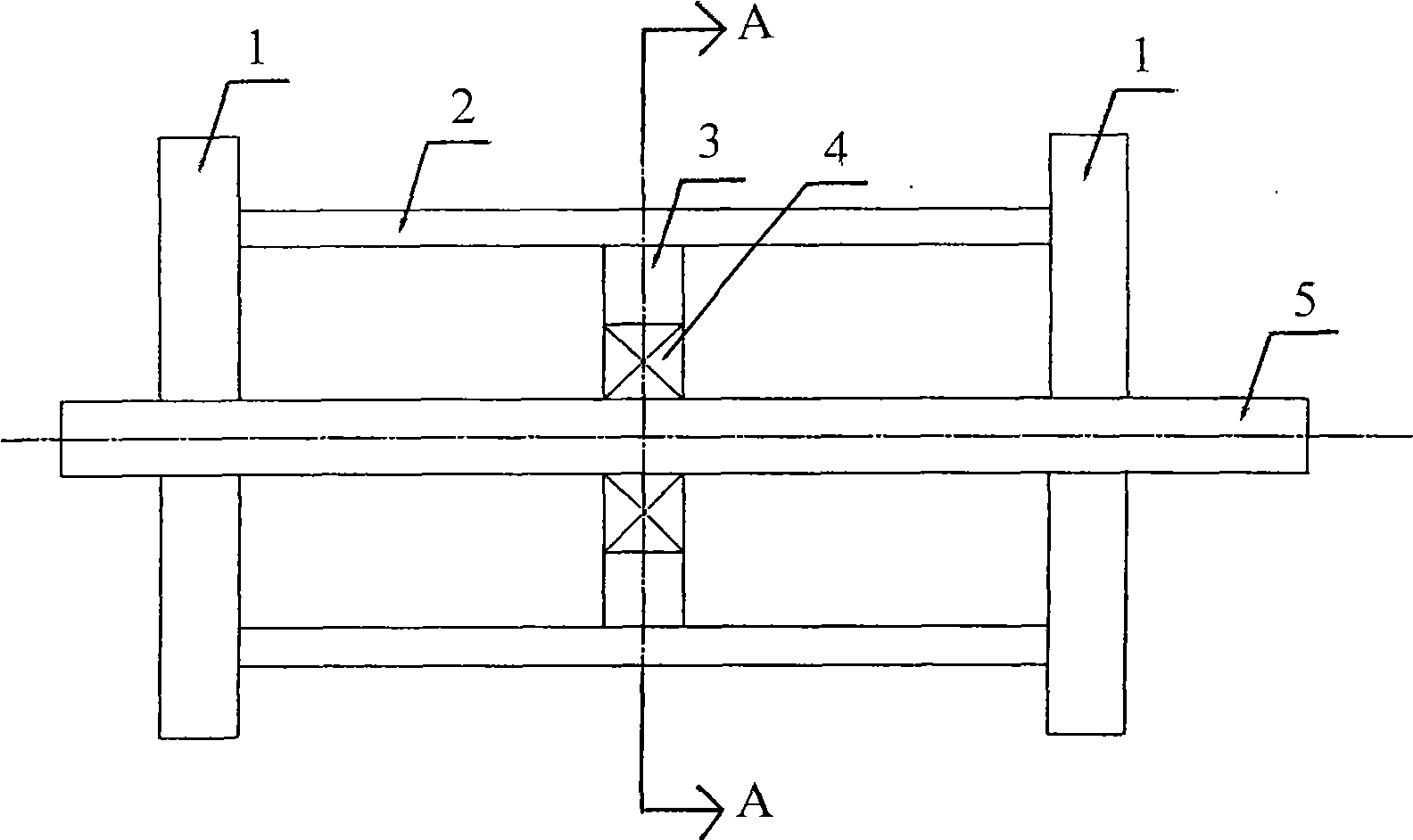

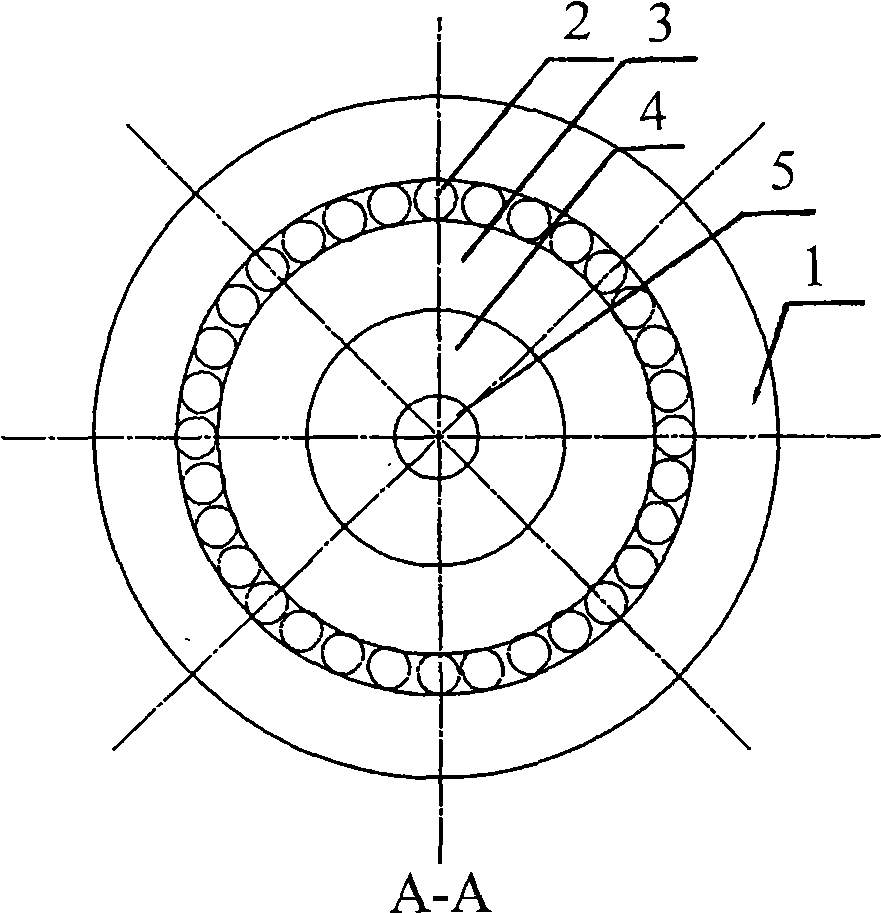

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises two fixed rings 1, a plurality of elastic strips 2 and rolling bearings 4; the same circumference of the plurality of elastic strips 2 is equally fixed on the end faces of the two fixed rings 1 to form a squirrel cage, and the shaft 5 in the squirrel cage and The inner ring of the rolling bearing is fixedly connected, and the two fixed rings 1 are fixed on the machine. When the shaft 5 rotates, the outer ring of the rolling bearing contacts with the elastic strip to form a squirrel-cage elastic support.

[0020] Or the outer ring of the rolling bearing is fixedly connected to the bearing support 3, and the bearing support 3 is in contact with the elastic strip 2 to form a squirrel-cage elastic support.

Embodiment 2

[0022] The invention includes two fixed rings, multiple elastic strips and sliding bearings. A plurality of elastic strips are equally fixed on the end faces of two fixed rings on the same circumference to form a squirrel cage. The shaft in the squirrel cage is fixedly connected to the inner sleeve of the sliding bearing. The two fixing rings are fixed on the machine. When the shaft rotates, the outer sleeve of the sliding bearing The sleeve is in contact with the elastic strip to form a squirrel-cage elastic support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com