Die clamping device for injection molding machine

A technology of injection molding machine and mold clamping device, which is applied in the field of connection mechanism, and can solve problems such as inability to completely absorb deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach ]

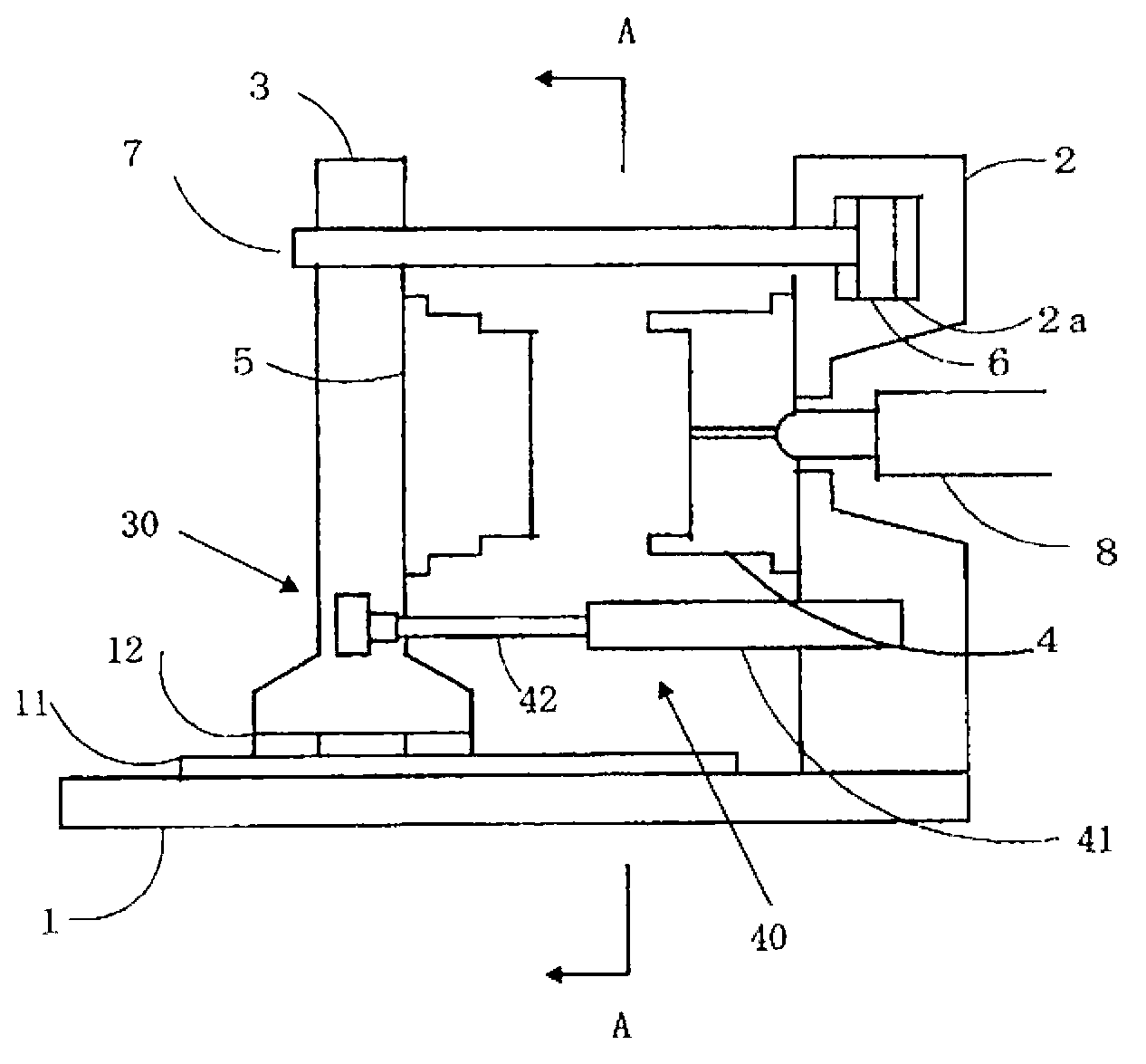

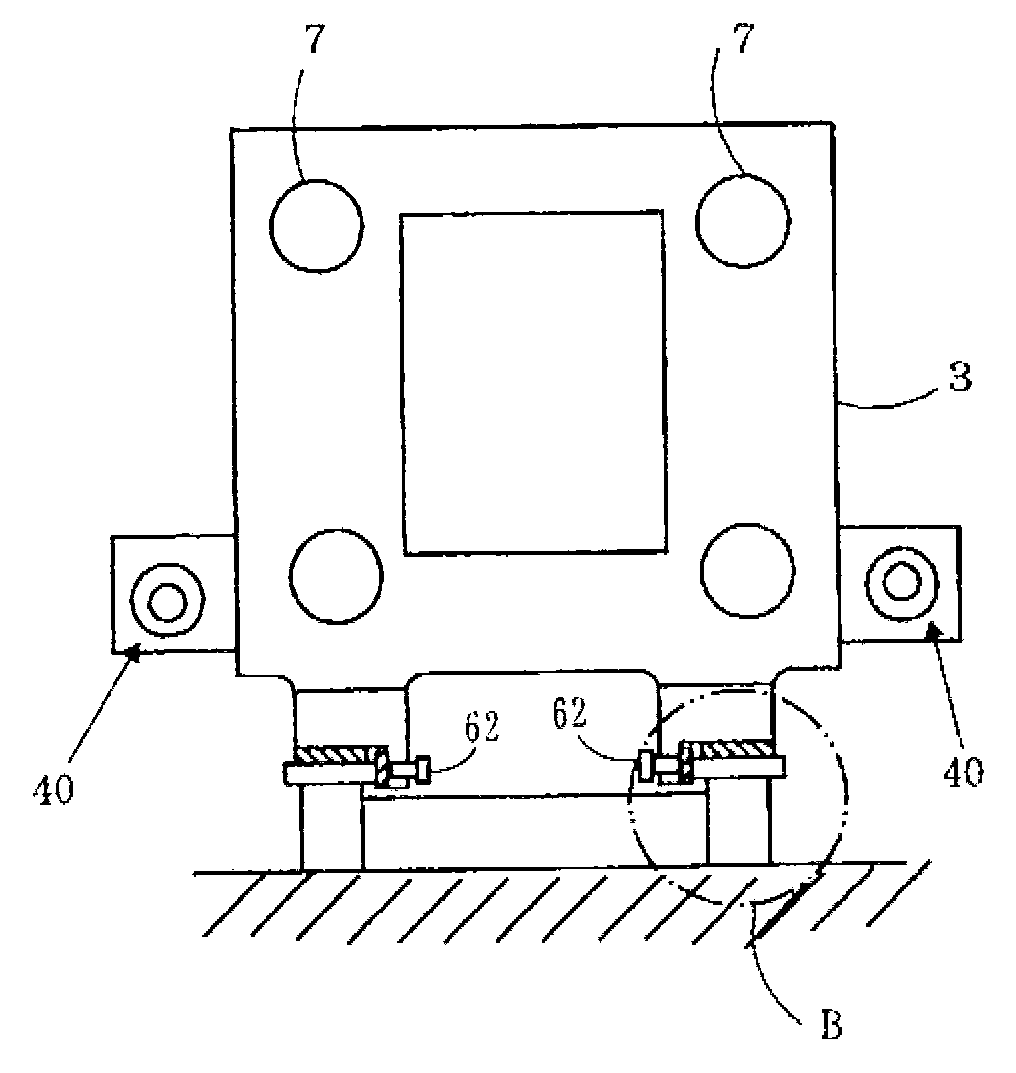

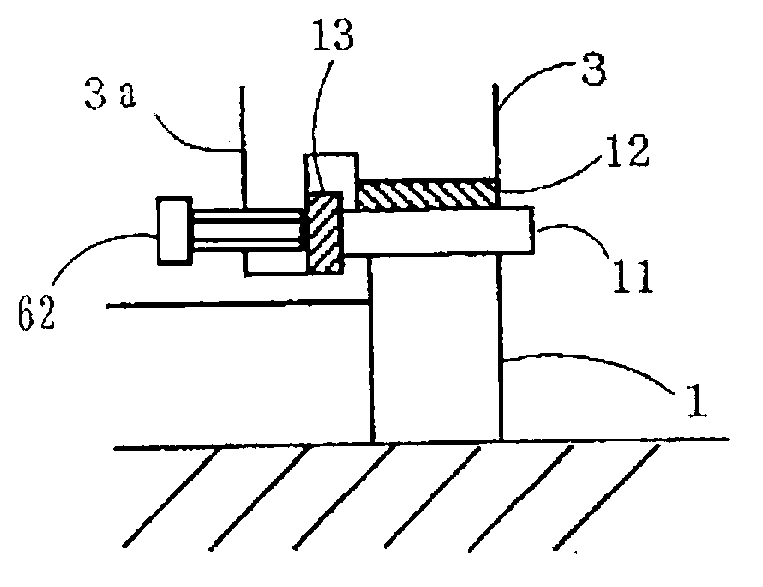

[0093] The first embodiment will be described based on the drawings. figure 1 is a side view of the injection molding device of the present invention; figure 2 yes figure 1 The A-A profile; image 3 yes figure 2 Enlarged view of Part B of ; Figure 4 yes means figure 1 The top view of the mold plate and the mold plate opening and closing mechanism of the injection molding device (the double dotted line indicates the movable mold plate when the mold is opened); Figure 5 yes Figure 4 The detailed drawing of the mold plate and the joint part C of the mold plate opening and closing mechanism; Image 6 yes means Figure 4 The tilted top view of the movable die plate when the side guide plate has been asymmetrically worn; Figure 7 yes Image 6 Enlarged view of Part E of (Part 1); Figure 8 yes Image 6 Enlarged view of Part E of (Part 2); Figure 9 is expressed in Figure 4 The enlarged view of the front end position of the hydraulic piston rod at the joint part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com